Odor-resistant floor drain with gas-preventive barrel

A floor drain and gas-proof technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve problems such as poor floor leakage and deodorization effect, and achieve the effects of smooth drainage and simple structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

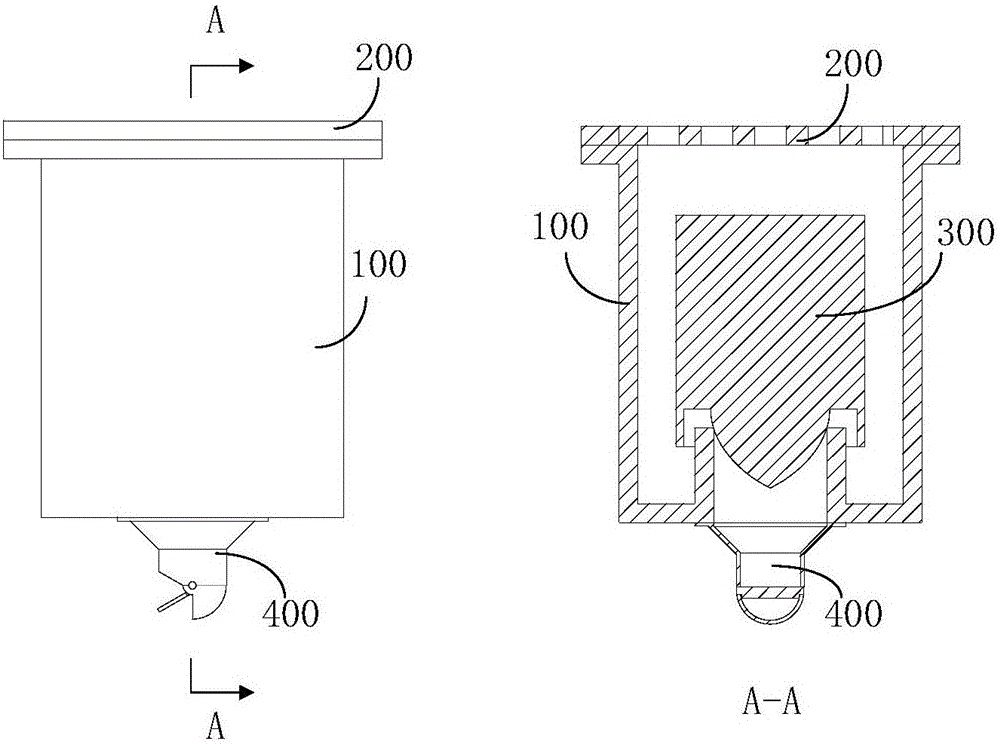

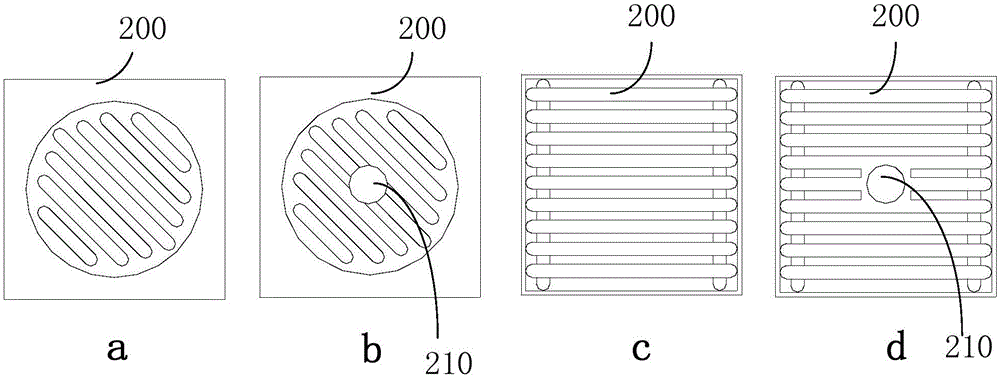

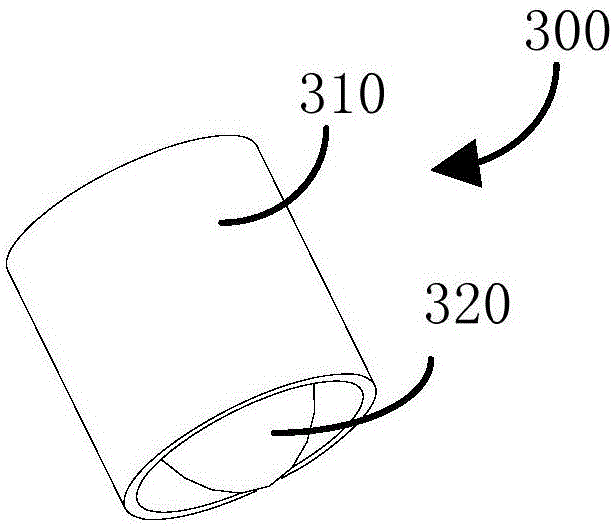

[0082] This embodiment provides an anti-odor floor drain with an air-proof cylinder, which includes a floor drain body, a floor drain cover and a float; the floor drain cover is arranged at the opening of the upper end of the floor drain body; the lower end of the floor drain body is connected to a drain pipe; the The float is arranged inside the floor drain body, the float is arranged above the drain pipe, the lower end of the float is provided with an air-proof cylinder, and the air-proof cylinder is set on the outside of the drain pipe, and the bottom of the float Cooperate with the top of the drain pipe and the inner wall of the floor drain body.

[0083] The working process of the floor drain is briefly described as follows: In the initial state, the float 300 is in contact with the water outlet 101 of the floor drain (the float 300 seals the water outlet 101 of the floor drain). The upward buoyancy of the 300 increases gradually. When the upward buoyancy of the water act...

Embodiment 3

[0110] This embodiment provides a floor drain, please refer to Figure 11 with Figure 12 ,

[0111] The floor drain includes: a floor drain body 100, a floor drain cover 200 and a float 300, wherein the floor drain cover 200 includes a cover wall and a cover top, the cover top is arranged below the cover wall, and the cover wall is detachably connected above the inside of the floor drain body 100; the floor drain body The lower end of 100 is connected with the drain pipe, the float 300 is bowl-shaped, and the float 300 is arranged above the water outlet 101 . The lower end of the float 300 is provided with an air-proof cylinder, and the air-proof cylinder is set on the outside of the drain pipe, and the bottom of the float 300 cooperates with the top of the drain pipe and the inner wall of the floor drain. When the floor drain cover 200 is in normal use ( Figure 11 ), the opening formed by the cover wall and the top of the cover faces downward, and after the floor drain c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com