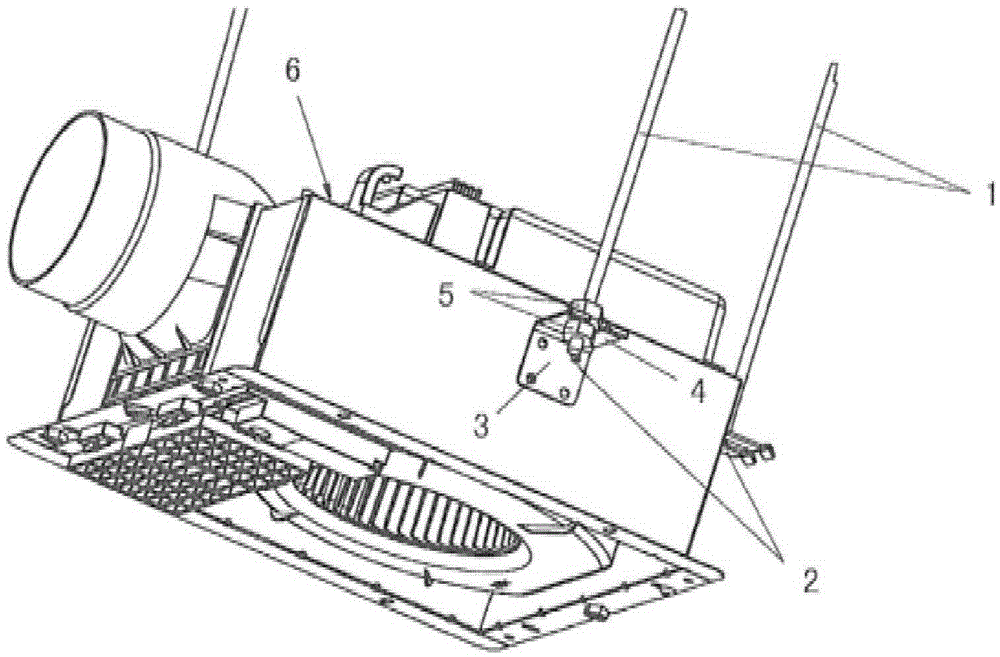

Integrated ceiling mounting support

A technology for installing brackets and integrated ceilings, which is applied to ceilings, building components, buildings, etc., can solve the problems of complicated installation, non-adjustable, and many installation tools, and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

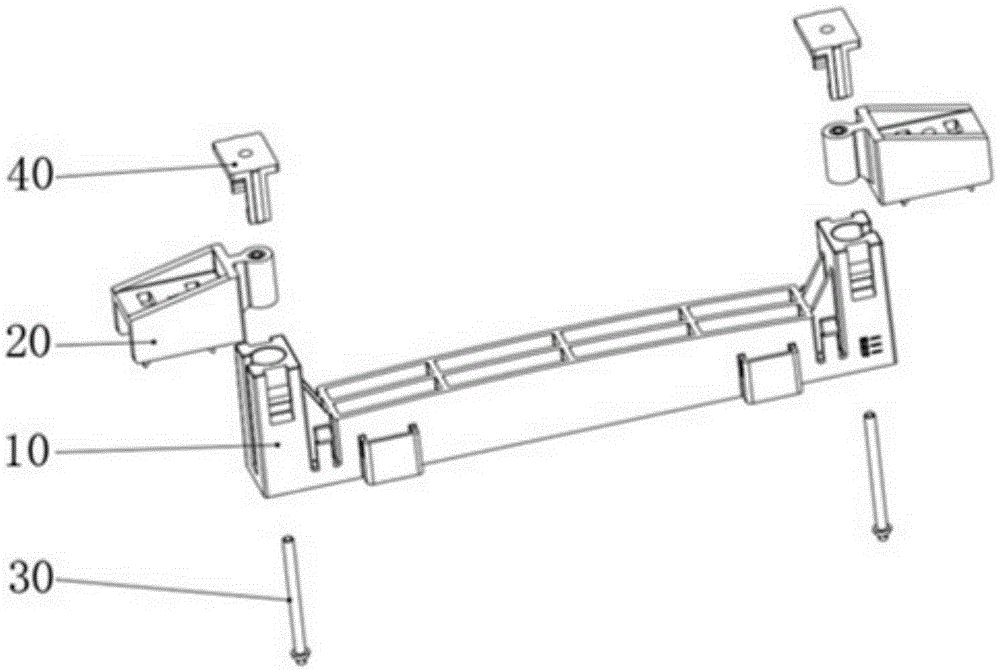

[0029] see figure 2 , which is an exploded schematic view of the overall structure of the integrated ceiling mounting bracket of the present invention. The integrated ceiling installation bracket includes a hoisting beam 10 , a hoisting support 20 , an adjusting screw 30 and a hoisting limit block 40 .

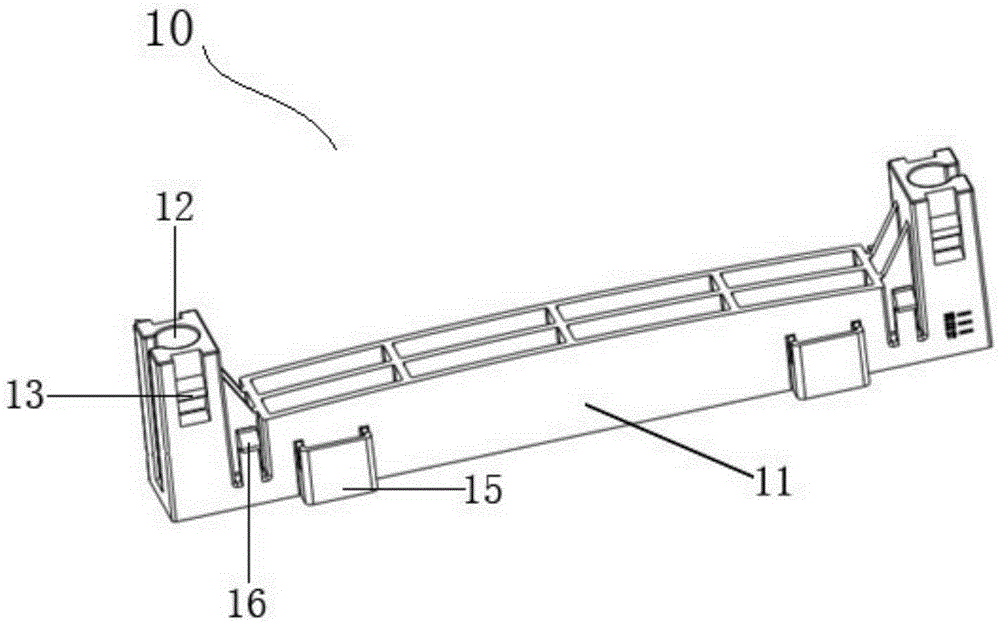

[0030] see image 3 , which is a structural schematic diagram of the suspension beam 10 . The hoisting beam 10 includes a beam 11 , a slideway 12 arranged at the end of the beam 11 , a slot 13 arranged outside the slideway 12 , a support frame 15 and a self-locking buckle 16 arranged on the side wall of the beam 11 . In this embodiment, the slideway 12 runs through the upper end surface and the lower end surface of the beam 11 in the vertical direction. The support frame 15 is mated and connected with the installation groove of the matching installation item, and the self-locking buckle 16 is matched and connected with the anti-loosening boss of the matching installation i...

Embodiment 2

[0040] see Figure 10 , which is a schematic diagram of the structure of the connected components in this embodiment. The content of this embodiment is basically the same as that of Embodiment 1, the difference is that the hoisting support 20 further includes a hollow positioning column 26 disposed below the support plate 24 . The support plate 24 is provided with a positioning hole corresponding to the hollow positioning post 26 .

[0041] see Figure 11 , which is a schematic diagram of the installation of the integrated ceiling installation bracket and the keel in this embodiment. When the width of the keel A exceeds the support range of the two elastic buckles 25 in the lifting support 20, the two buckles 25 are broken off, and the self-tapping screw B is used to connect the positioning hole and the positioning hole of the lifting support 20 The column 26 passes through, and directly locks the hoisting support 20 and the keel A with screws. Through this structural arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com