Trim panel integrated wall space construction method

A construction method and technology for interior panels, applied in covering/lining, architecture, building structure, etc., can solve the problems of environmental protection and personalized artistic effects of the final product, which can be avoided, and achieve the omission of wet work construction process and work efficiency. High and cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

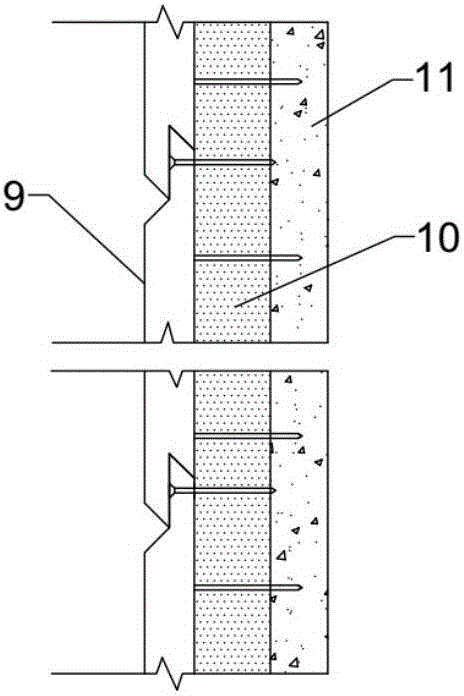

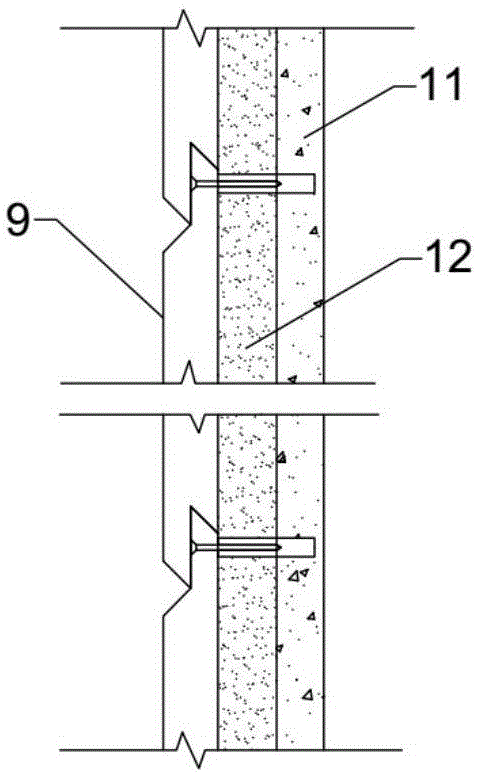

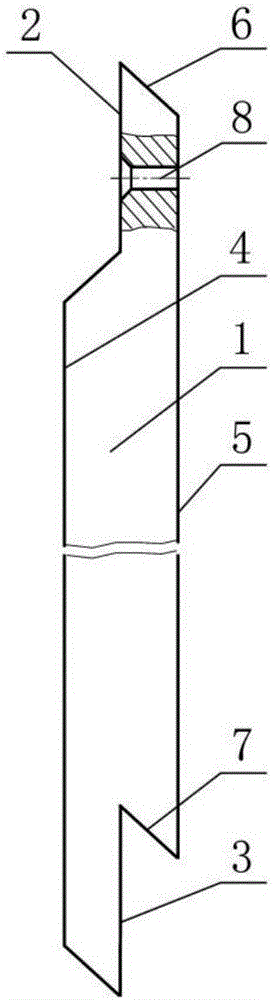

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

[0031] The construction method of the interior trim panel integrated wall surface in this embodiment specifically includes the following steps:

[0032] (1) Inspection of interior wall structure

[0033] According to the customer's requirements and the quality of the internal wall structure on site, in order to select the appropriate leveling construction method, the quality of the base layer of the wall surface must be inspected before the official star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com