Inclined tube h-type underwater crude oil online separation method

A separation method, inclined tube technology, applied in the field of marine engineering, can solve problems such as insufficient separation time, small oil-water interface coverage area, etc., to achieve the effect of ensuring the safety of production operations and simplifying the gathering and transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

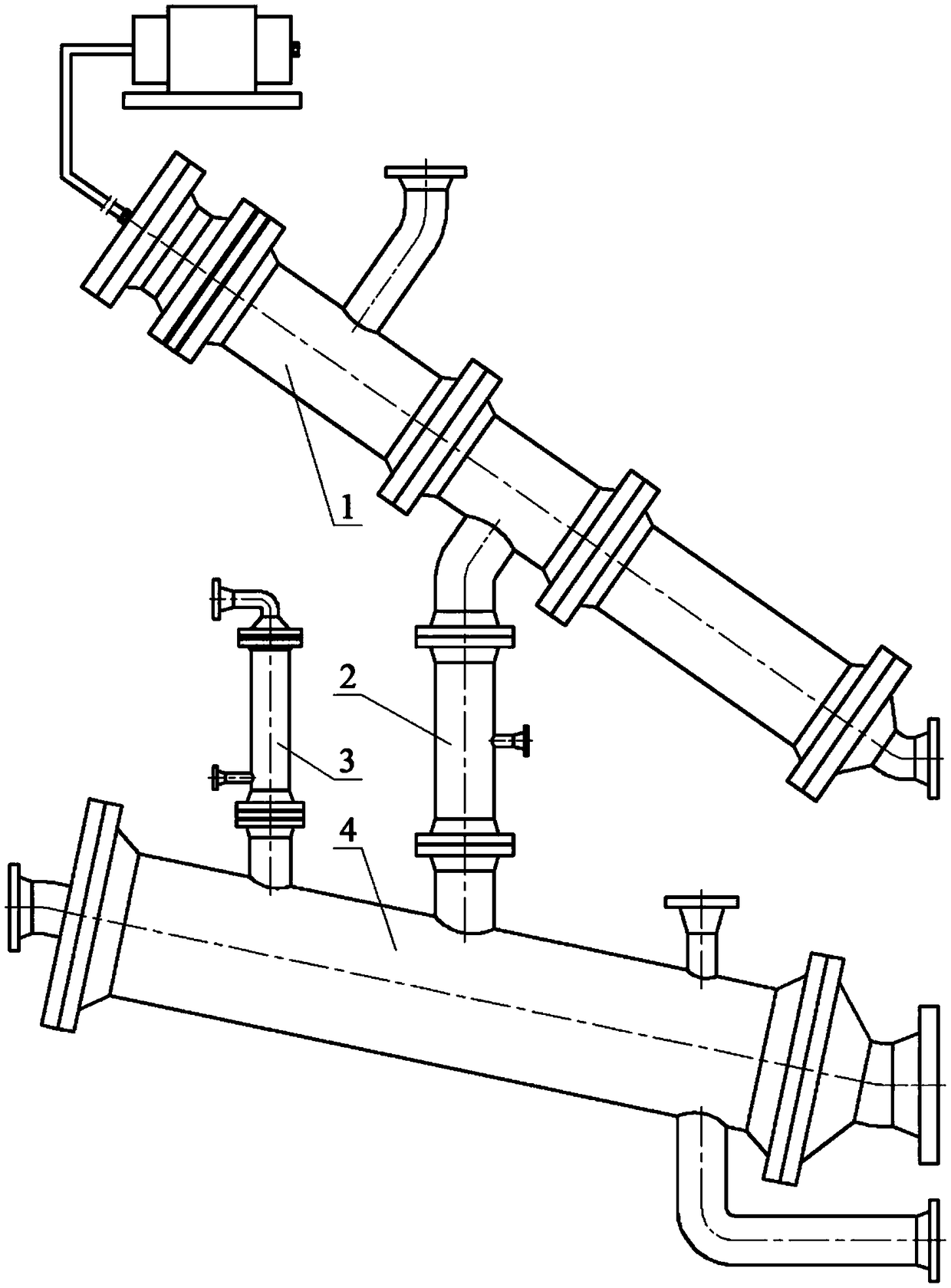

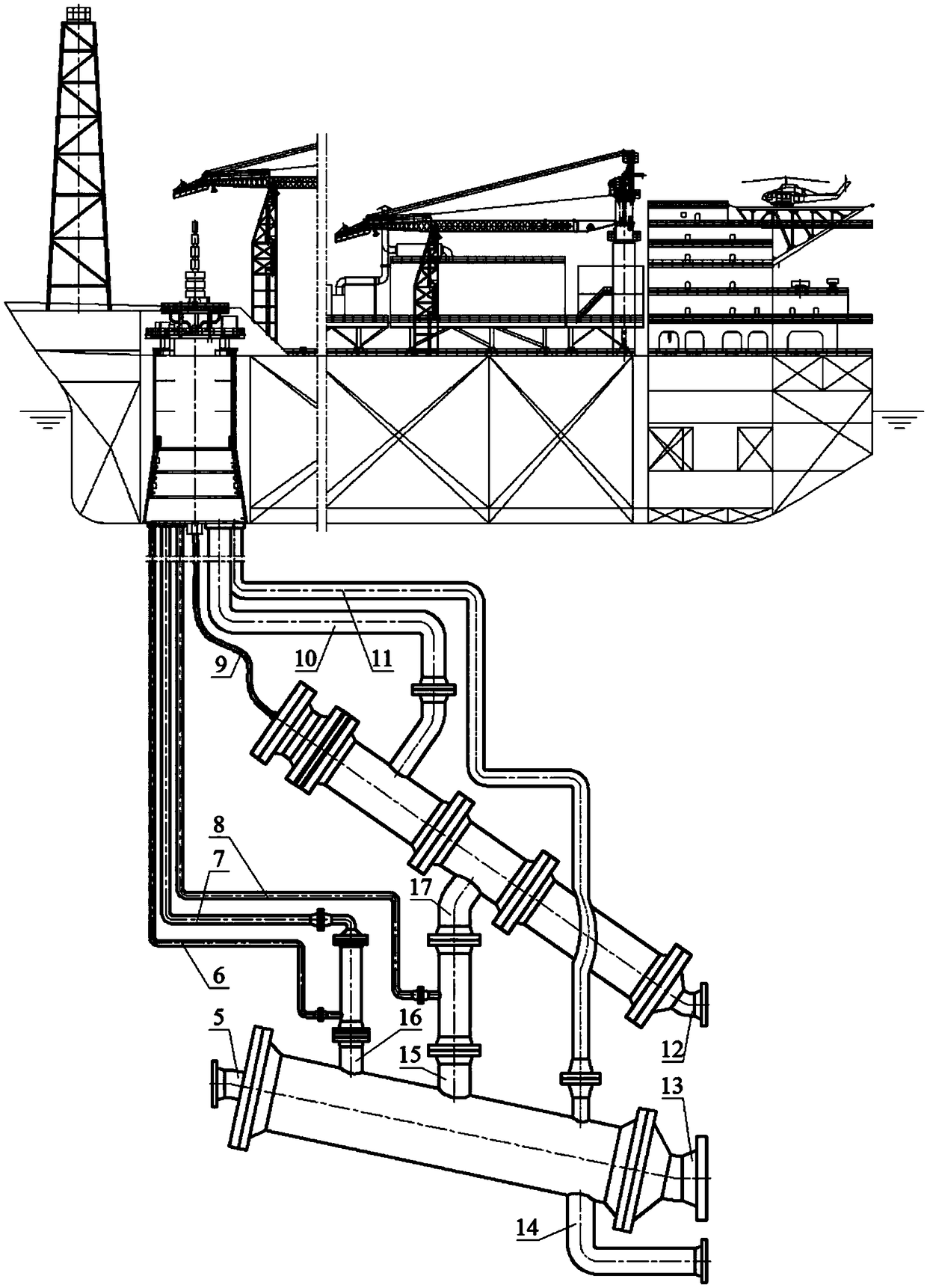

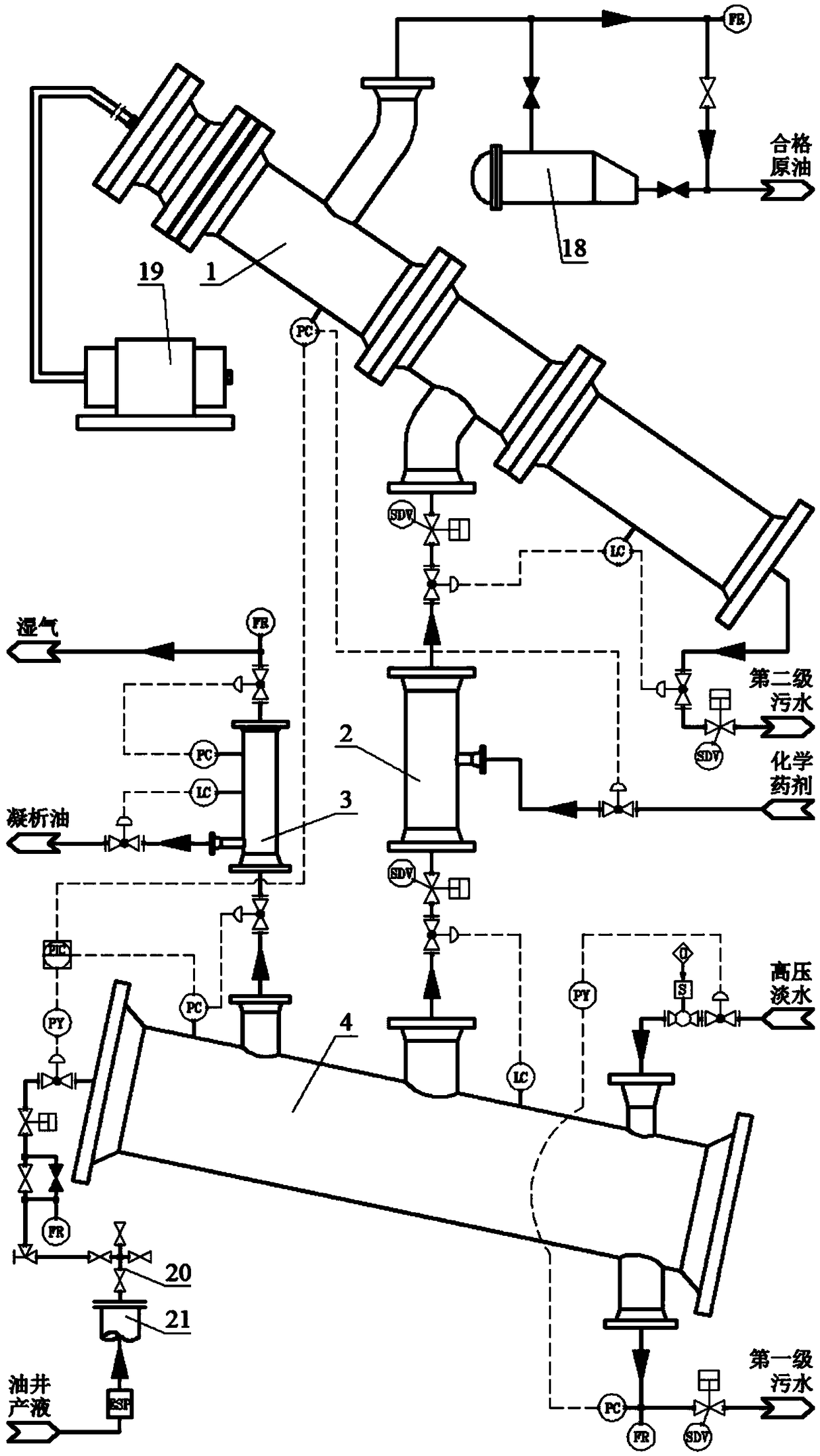

[0029] exist figure 1 Among them, the inclined tube H-type underwater crude oil online separation system is composed of the second-stage tubular electric dehydrator 1, the mixer 2, the gas-liquid separator 3, the first-stage tubular separator 4 and the underwater online control system. The underwater crude oil online separation system adopts the first-stage tubular separator 4 and the second-stage tubular electric dehydrator 1 two-stage tubular separators connected in series to realize rapid and deep separation of crude oil, and the two-stage tubular separators are all inclined Arrangement, so as to organically combine the vertical and horizontal online separation technologies of crude oil, and at the same time, the two-stage pipe separators are arranged up and down respectively and kept connected through the mixer 2 in the middle, so that the entire separation system presents an H-shaped layout mode as a whole.

[0030] exist figure 1 Among them, the problem of changing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com