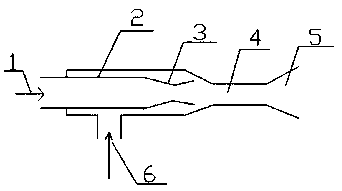

Method for simplifying coalbed methane gathering and transporting technology by using Venturi ejector

A venturi and coalbed methane technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of high manpower, material resources, and high operating costs, and achieve simplified gathering and transportation processes, reduced depreciation costs and The effect of production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Yanchuan South Coalbed Gas Field takes the existing reserve resources of the No. 2 coal seam of the Permian Shanxi Formation as the development object, and has built (1#, 2#, 3#, 4#) 4 gas gathering stations and 1 central dehydration station, of which 4# The gas-gathering station and the central dehydration station are combined to form a gas-gathering central dehydration station. Gathering pipelines are built between the gas gathering station and the dehydration station of the gas gathering center. The overall layout of the 500 million m3 production and construction surface project of Yanchuan South Coalbed Methane adopts the second-level gas-gathering station layout method to set up the station. It is transported to the dehydration station of the gas gathering center for repressurization, deep dehydration, and export.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com