Oil field well casing gas recovery device and process

A technology of oil well casing and recovery device, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of wasting oil and gas resources, increasing carbon emissions, and polluting the atmospheric environment, so as to reduce construction investment and Effects of operation and management cost, increase of gathering and transportation radius, and simplification of technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

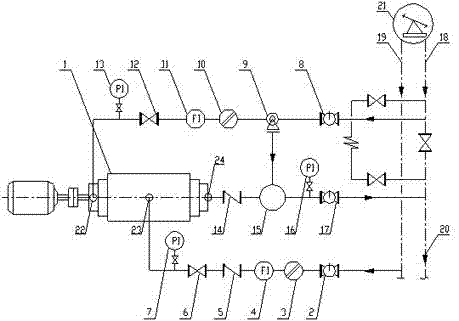

[0015] like figure 1 As shown, an oil well casing gas recovery device in an oil field is characterized in that it includes a synchronous rotary compressor 1, crude oil 18 from the wellhead, casing gas 19 from the wellhead, valve pipeline and pumping unit 21, and crude oil 18 from the wellhead passes through The first pipeline and synchronous The first inlet 22 of the rotary compressor 1 is connected to the pipeline; the casing gas 19 from the wellhead passes through the second ball valve 2, the second filter 3, the second flow meter 4, and the second check valve 5 , The second pipeline of the second throttling valve 6 and the second pressure gauge 7 is connected to the second inlet 23 of the synchronous rotary compressor 1; the compression outlet 24 of the synchronous rotary compressor 1 passes through the outlet check The output pipeline connected in series with the return valve 14 , the buffer tank 15 , the outlet pressure gauge 16 and the outlet ball valve 17 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com