Well site throttling method and well site throttling system

A technology of well site and throttling device, which is applied to pipeline systems, wellbore/well components, production fluids, etc., can solve the problems of high cost, high cost of heating furnace maintenance, operation and salvage, and achieves simple operation, low cost, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

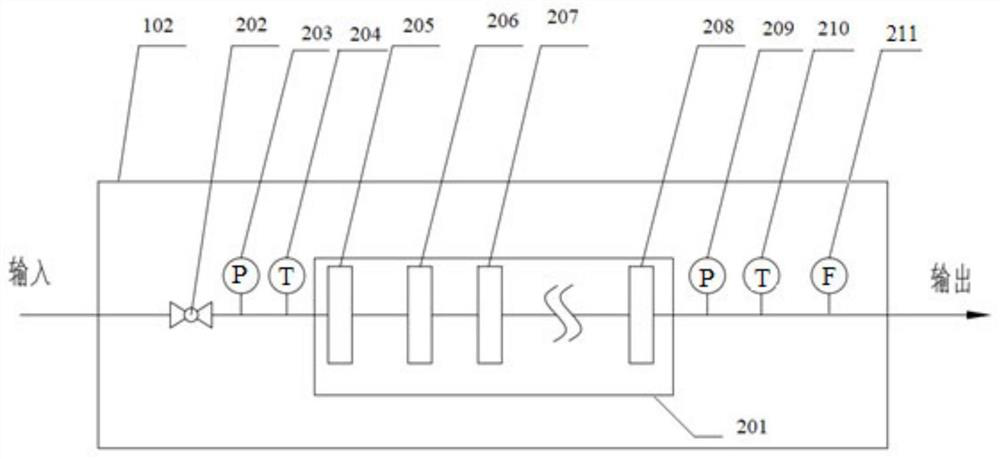

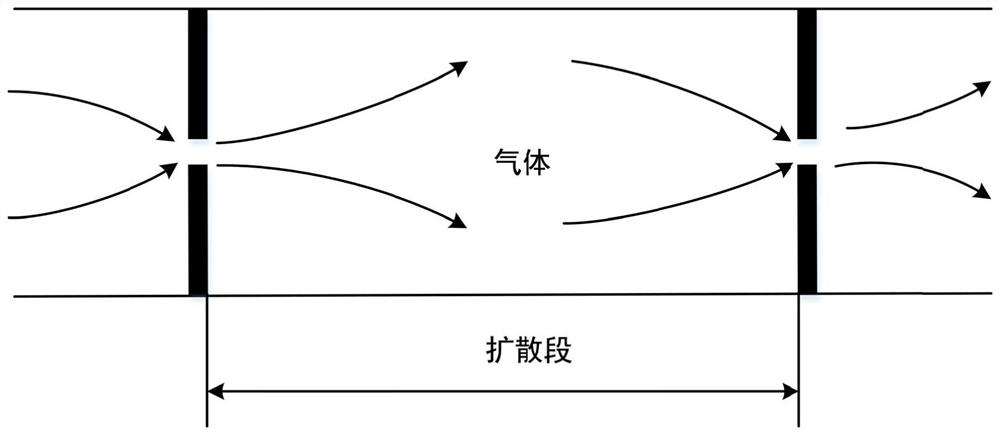

[0051] The specific implementation manner of the present application will be described below in conjunction with the accompanying drawings.

[0052] In this article, "upper", "lower", "front", "rear", "left", "right", etc. are only used to indicate the relative positional relationship between related parts, rather than to limit the absolute position of these related parts .

[0053] In this article, "first", "second", etc. are only used to distinguish each other, not to indicate the degree of importance and order, or the prerequisite for mutual existence.

[0054] Herein, "equal", "identical" and the like are not strictly restricted in the sense of mathematics and / or geometry, but also include errors understandable by those skilled in the art and allowed in manufacture or use.

[0055] Unless otherwise stated, a numerical range herein includes not only the entire range within its two endpoints, but also several subranges subsumed therein.

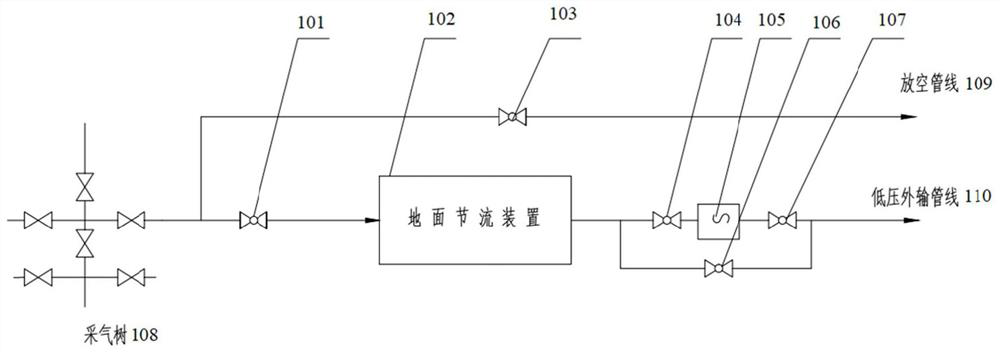

[0056] This application provides a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com