Two-stage axial flow underwater pipeline online gas-liquid separation device

A gas-liquid separation device and underwater pipeline technology, which is applied in the direction of combined devices, separation methods, and dispersed particle separation, can solve the problems of high energy consumption, low oil-water separation efficiency, and energy loss in the gathering and transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

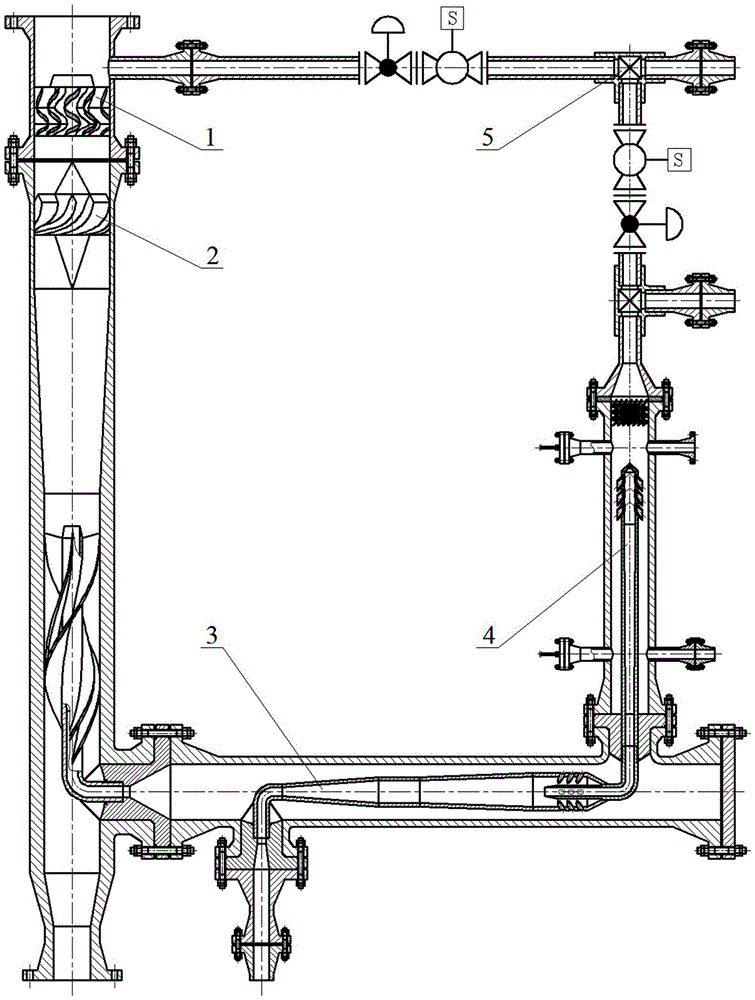

[0037] exist figure 1 Among them, the two-stage axial-flow underwater pipeline online gas-liquid separation device consists of a gas-liquid homomixer 1, a first-stage axial flow device 2, a second-stage axial flow device 3, a scrubber balancer 4, a cleaning pipe 5 and a gas-liquid separation control system composition. The gas-liquid homogenizer 1, the primary axial flow device 2, the secondary axial flow device 3 and the scrubber balancer 4 are sequentially connected to each other through flanges, and the connected whole presents a U-shaped special structure. The cleaning pipe 5 Connect the gas-liquid homogenizer 1 through the flange plate and connect the scrubber balancer 4 through the exhaust tee. The inlet of the gas-liquid separation device is connected to the pipeline of the underwater wellhead Christmas tree through the homogenizing cylinder of the gas-liquid homomixer 1, the first-stage liquid discharge pipe of the first-stage axial flow device 2, and the second-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com