Quality identification method of pit sealing mud

A technology of quality identification and pit sealing mud, which is applied in the direction of removing certain components and weighing, can solve the problems of manpower consumption, waste of resources, and inaccurate individual judgment results, so as to achieve accurate and effective identification and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

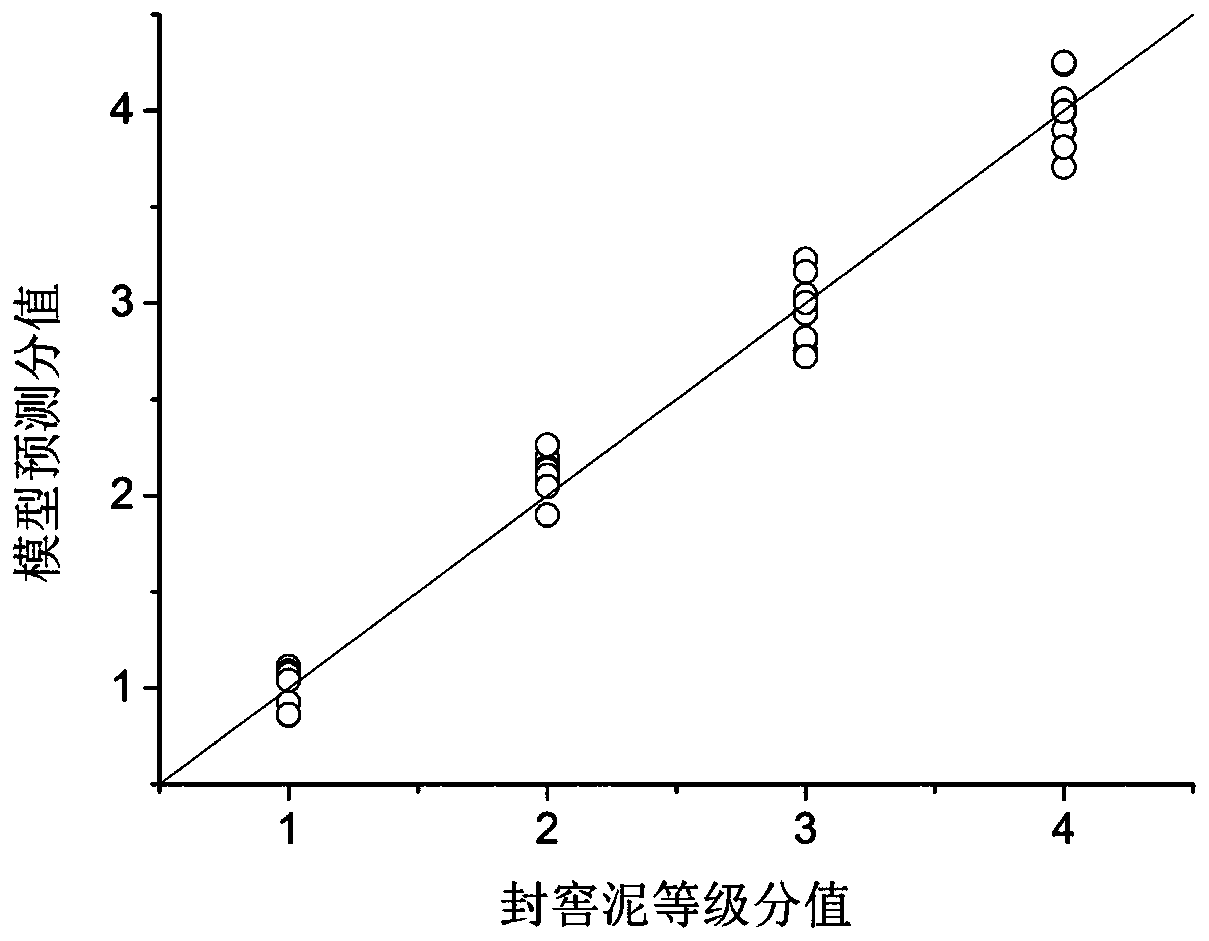

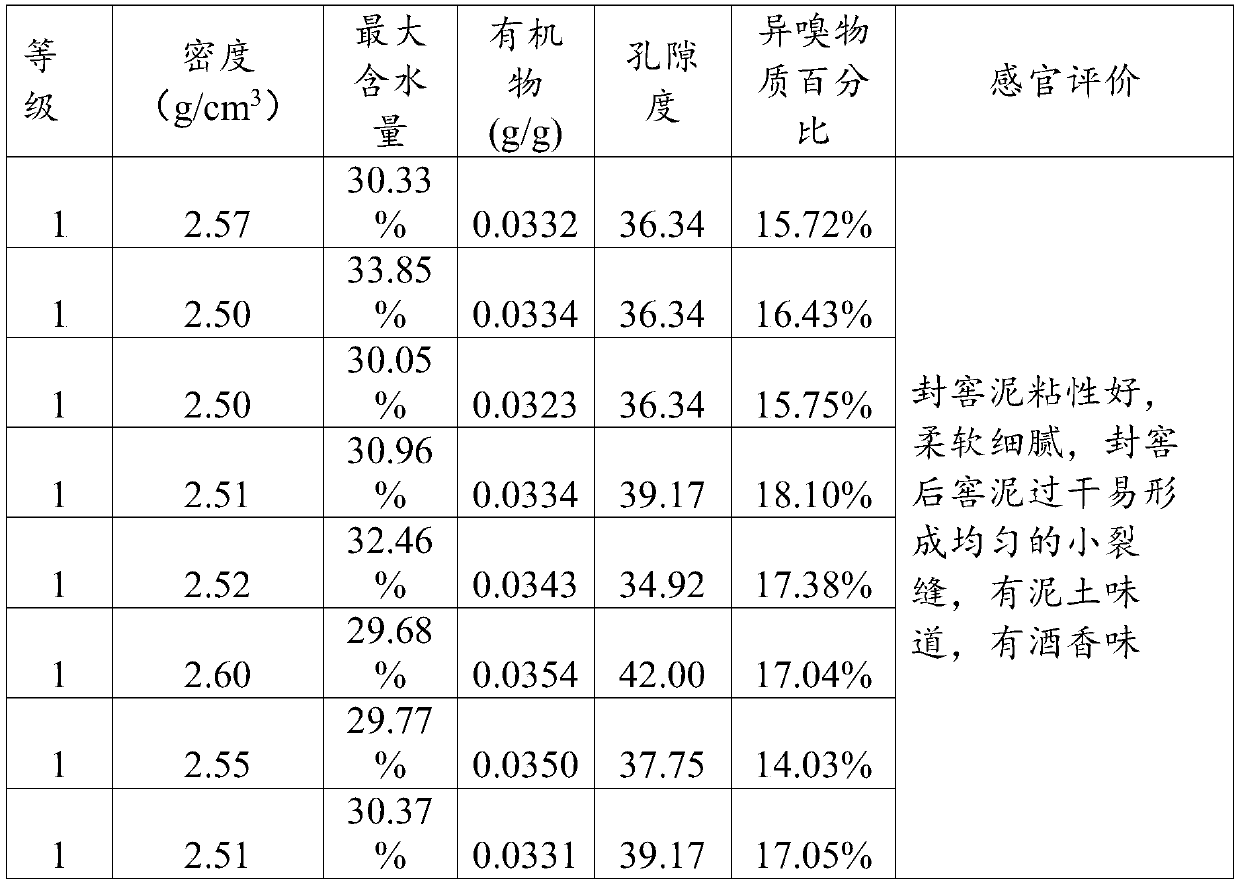

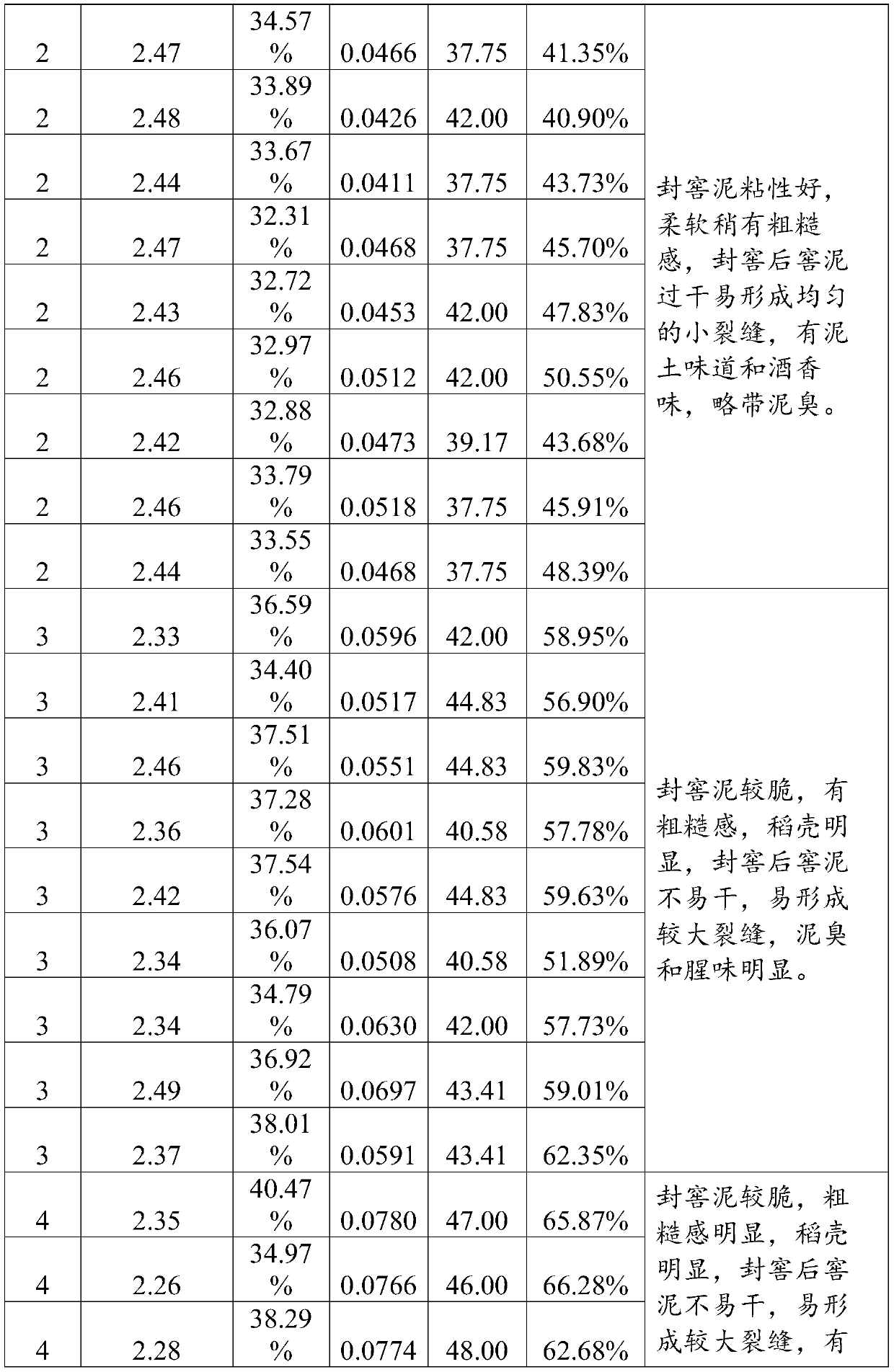

[0047] First, the quality-related parameters of multiple groups of sealing mud samples were measured using the above-mentioned measurement method provided by the embodiment of the present invention, including the density, maximum water content, organic matter content, porosity, and percentage of odorous substances of the sealing mud samples. The results of the measurement are shown in Table 1 below.

[0048] Table 1 Determination data and sensory evaluation of quality-related parameters of various grades of pit sealing mud samples

[0049]

[0050]

[0051]

[0052] The grading in Table 1 here is based on the sensory evaluation of the sealing mud samples and previous practical experience. In order to ensure that the sensory evaluation of cellar sealing mud samples is sufficiently accurate, different from the usual sensory evaluation of cellar sealing mud samples, this time each group of cellar sealing mud samples is evaluated by technicians in multiple shifts (for exa...

Embodiment 2

[0070] In the present embodiment, the organic content X of the sealing mud of a certain round of wine is measured 1 0.0342g / g, density X 2 2.47 g / cm 3 , the maximum water content X 3 31.52%, porosity X 4 is 38.85, the percentage of different smell substances X 5 It is 12.87%, according to the formula Y=K·X+b=3.124+23.573 X 1 -2.207X 2 +3.800X 3 +0.033X 4 +1.578X 5 . The result is 1.2, that is, the grade of sealing mud is about 1, and the effect is good.

Embodiment 3

[0072] In the present embodiment, the organic content X of the sealing mud of a certain round of wine is measured 1 0.0466g / g, density X 2 2.41g / cm 3 , the maximum water content X 3 31.81%, porosity X 4 is 38.95, the percentage of different smell substances X 5 It is 39.78%, according to the formula Y=K·X+b=3.124+23.573 X1 -2.207X 2 +3.800X 3 +0.033X 4 +1.578X 5 . The result is 2.0, that is, the grade of sealing mud is about 2, and the effect is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com