Single-tube high-fiber-count stainless optical unit production method and corresponding tooling structure thereof

A production method, stainless steel technology, applied in optical components, fiber mechanical structures, light guides, etc., can solve the problems of inability to meet the needs of communication, poor load bearing and electrical performance of optical units, and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

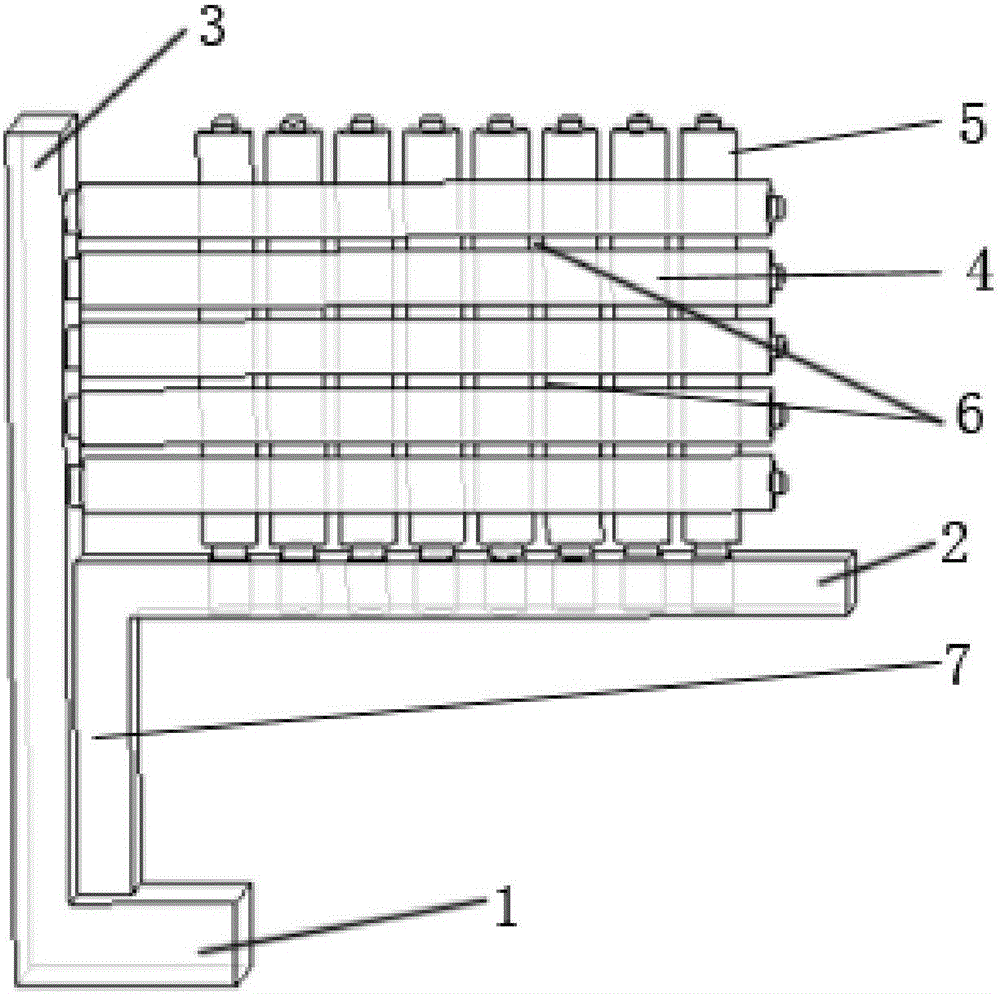

[0017] A method for producing a single-tube stainless steel optical unit with a large core count. The stainless steel tube is pre-processed, and then the optical fiber and grease are introduced into the stainless steel tube. The optical fiber and the grease are respectively introduced through the optical fiber catheter and the grease catheter, and the optical fiber is introduced before the fiber catheter , Pre-pass several optical fibers through a set of tic-tac-toe rollers to ensure that the optical fibers are divided into a number of equal parts and then pass through independent flow channels in the corresponding tic-tac-toe rollers, and enter the optical fiber conduit after the split.

[0018] The size of the ointment conduit is slightly smaller than the inner diameter of the stainless steel tube; the size of the optical fiber conduit should be maximized under the premise of satisfying the amount of ointment introduced to reduce the action resistance of the optical fiber during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com