Shale gas horizontal well refracturing technological process and design method

A technology of repeated fracturing and process flow, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as difficulty in starting pressure, long construction period, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

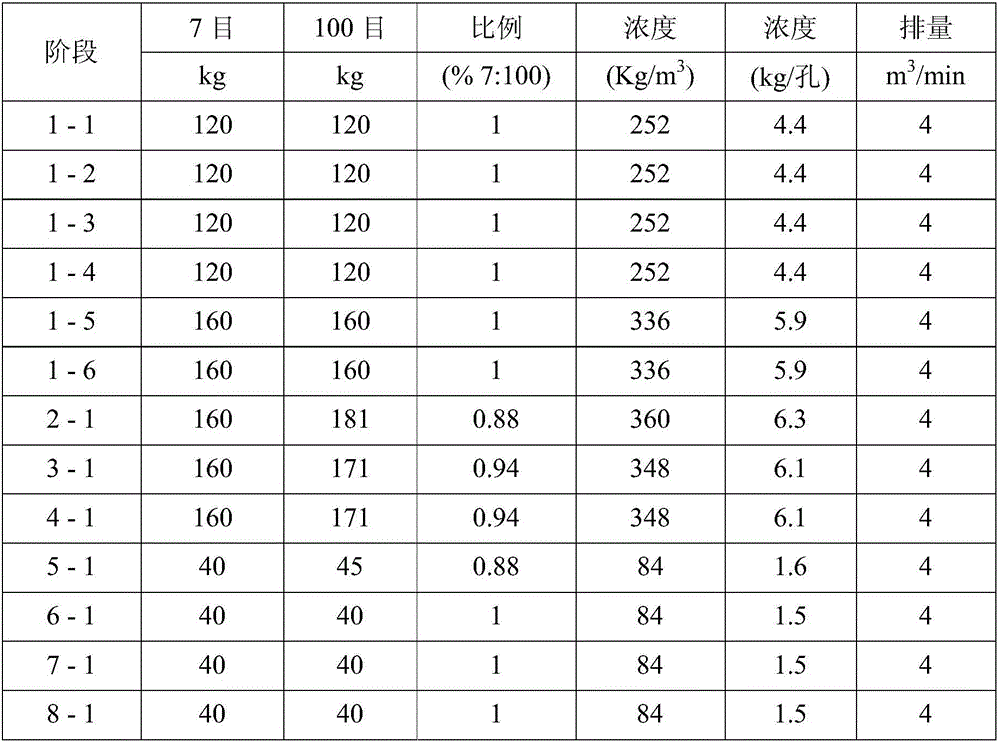

[0098] This embodiment provides a shale gas horizontal well refracturing process and design method, the flow chart is as follows figure 1 shown, from figure 1 It can be seen that the process flow and design method include the following steps:

[0099] (1) Steps to determine wells in selected areas for refracturing of shale gas horizontal wells

[0100] (1) Data collection: collect basic completion information, productivity data, production pressure and production, measure data, fracturing construction, post-fracture report, and microseismic results of all old shale gas horizontal wells in a target oil and gas well block , petrophysical data, well logging, special well logging, logging interpretation, geophysical properties, geomechanical data and other related data to clarify the criteria for judging the reservoir quality index, completion index, and productivity index of the target oil and gas block , and at the same time collect information about adjacent wells;

[0101] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com