Classification and discrimination system in metallurgical balling process

A ball forming and sub-classification technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of index number and sample dimension expansion, pellet classification, difficult to realize, etc., and achieve the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

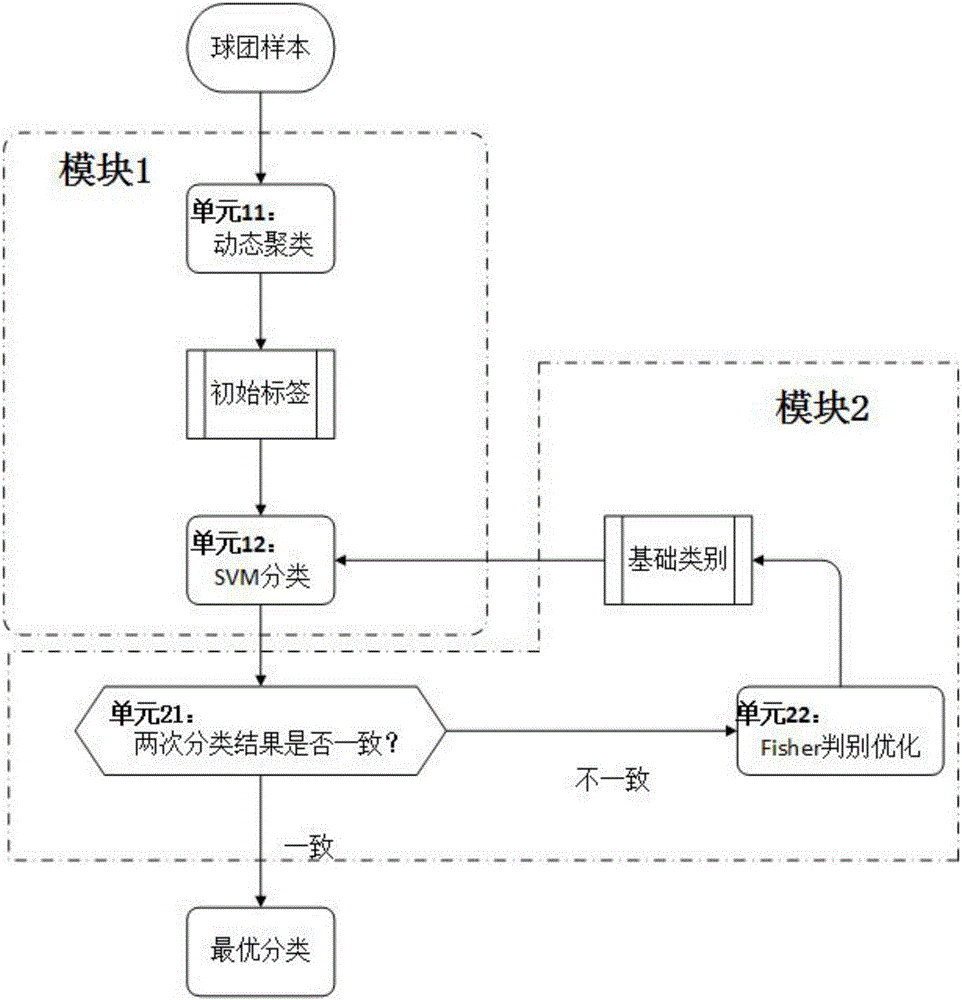

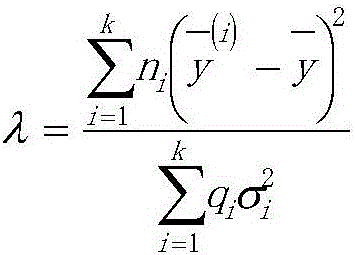

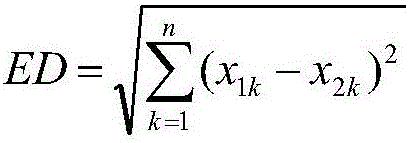

[0024] The invention relates to a classification and discrimination system in the metallurgical spheroidizing process, and the system is mainly composed of a clustering and classification module and a discrimination and optimization module. The clustering classification module mainly includes two parts: dynamic clustering unit and SVM classification unit: first, a set of initial labels is obtained by dynamic clustering, and then the SVM classification model is constructed based on the initial labels. The discriminant optimization module mainly includes a discriminant unit and a Fisher optimization unit: the discriminant unit discriminates the classification result obtained by the SVM classification from the last neighbor classification result: if the two classification results are consistent, the optimal classification method can be obtained directly; If the classification results are inconsistent, the Fisher optimization unit uses the Fisher discriminant principle to optimize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com