Method for cleaning surface contaminants of wafer through twin-fluid atomization

A atomization cleaning and two-phase flow technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of graphic structure damage, large atomized particle size, small atomized particle size, etc., and achieve effective cleaning , Efficient removal efficiency, optimized cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

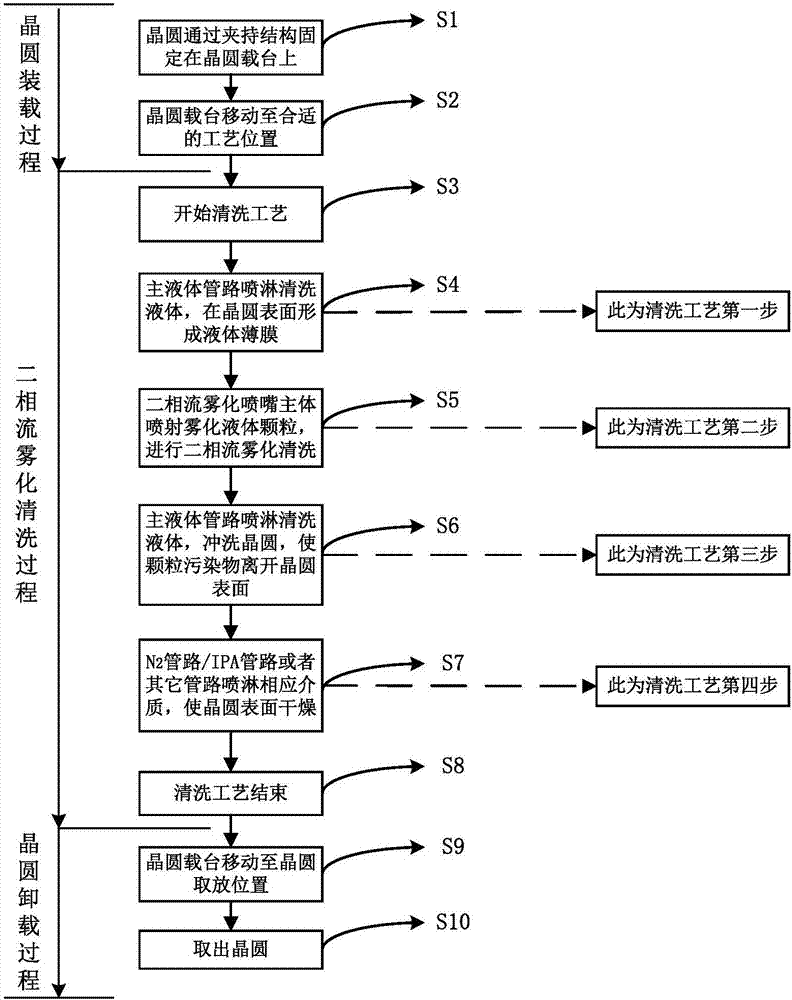

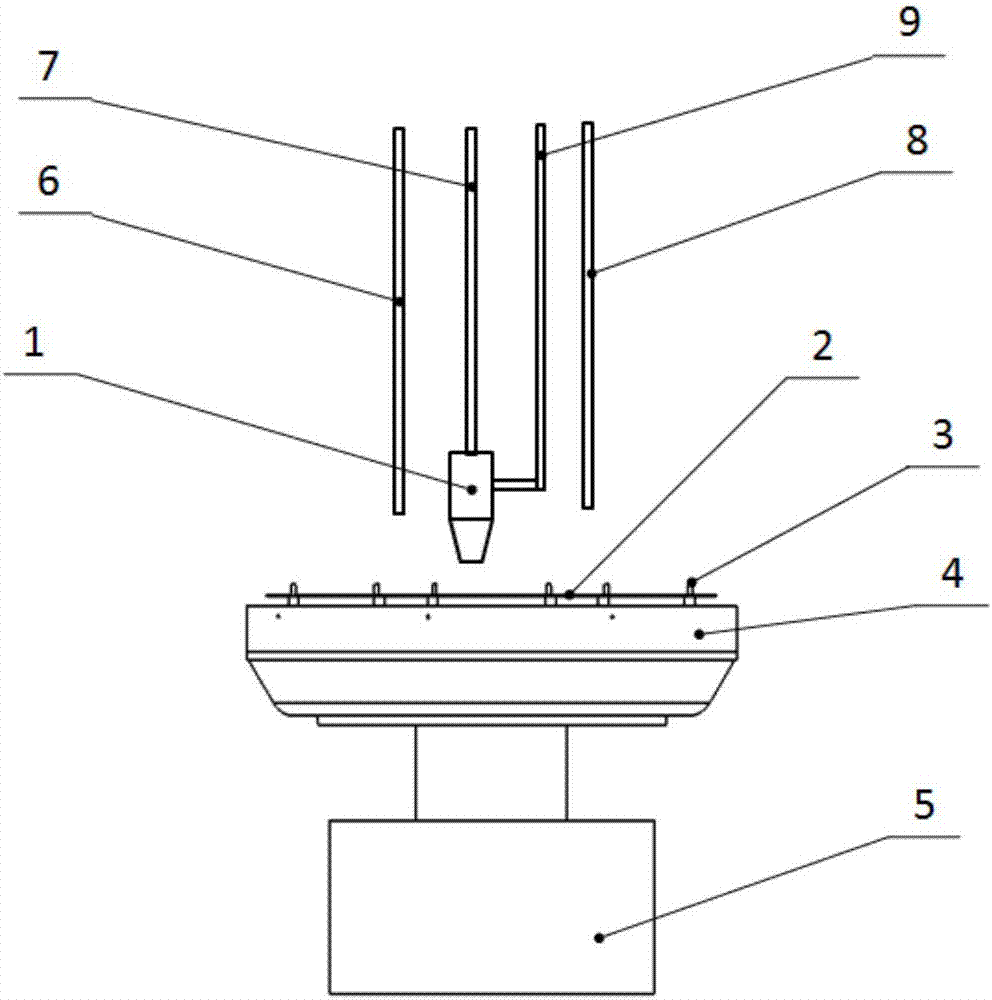

[0027] The core idea of the present invention is: a kind of method of the present invention adopts two-phase flow atomization to clean wafer surface pollutant, realizes through the following steps:

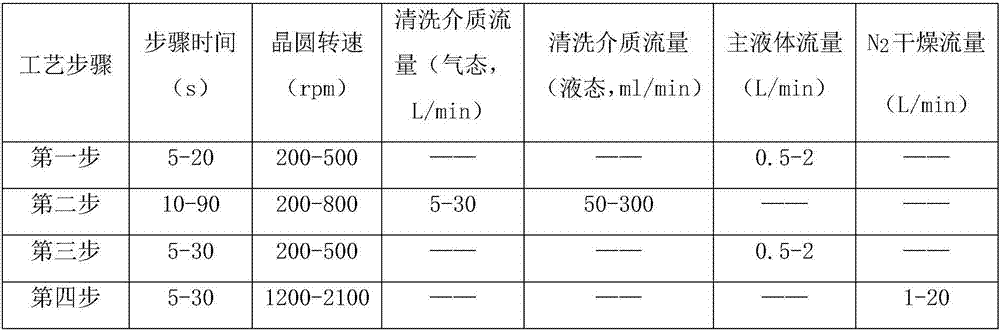

[0028] Step 1: Make the wafer rotate at the first speed, spray the first cleaning liquid with the first flow rate on the surface of the wafer through the main liquid pipeline, so as to form a liquid film on the surface of the wafer, and perform a first-time cleaning on the surface of the wafer. cleaning;

[0029] Step 2: Make the wafer rotate at the second speed, close the main liquid pipeline, and pass the second flow rate of gaseous cleaning medium and the third flow rate of liquid cleaning medium into the two-phase flow atomizing nozzle to pass the two-phase flow The atomizing nozzle sprays the modulated atomized liquid particles to the surface of the wafer, and performs two-phase flow atomization cleaning on the surface of the wafer at a second time;

[0030] Step 3: Make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com