Device for preparing air aqueous foam in pneumatic mode

A foam and air technology, applied in the field of fire-fighting equipment, can solve the problems of cumbersome maintenance and inspection process, complicated process, inconvenient use, etc., achieve broad application prospects and social benefits, simple device structure, and realize the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

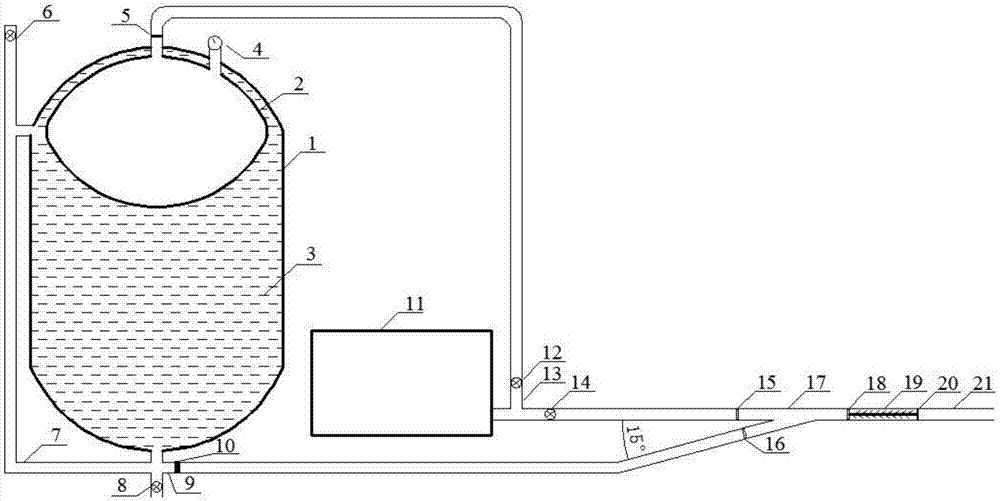

[0015] A device for the pneumatic preparation of airborne aqueous foams such as figure 1 As shown, it consists of a foam liquid storage tank 1, an air bag 2, a foam liquid 3, a pressure gauge 4, quick connectors 5, 10, regulating valves 6, 8, 12, 14, a water level gauge 7, a four-way pipe 9, and an air compressor 11 , Right angle tee pipe 13, valve flange 15, 16, 18, 20, 15 ° tee pipe 17, mixer 18, foam outlet pipe 21 composition.

[0016] The air compressor 11 is connected to one end of the right-angle three-way pipe 13, and the other two ends of the right-angle three-way pipe 13 are respectively connected to the regulating valves 12 and 14. 15 communicates with one end of the inlet end of the 15° tee pipe 17; the air bag 2 is arranged inside the foam liquid storage tank 1; the pressure gauge 4 and the quick connector 5 are connected with the air bag 2 respectively, and are respectively exposed in the middle of the top of the foam liquid storage tank 1 and the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com