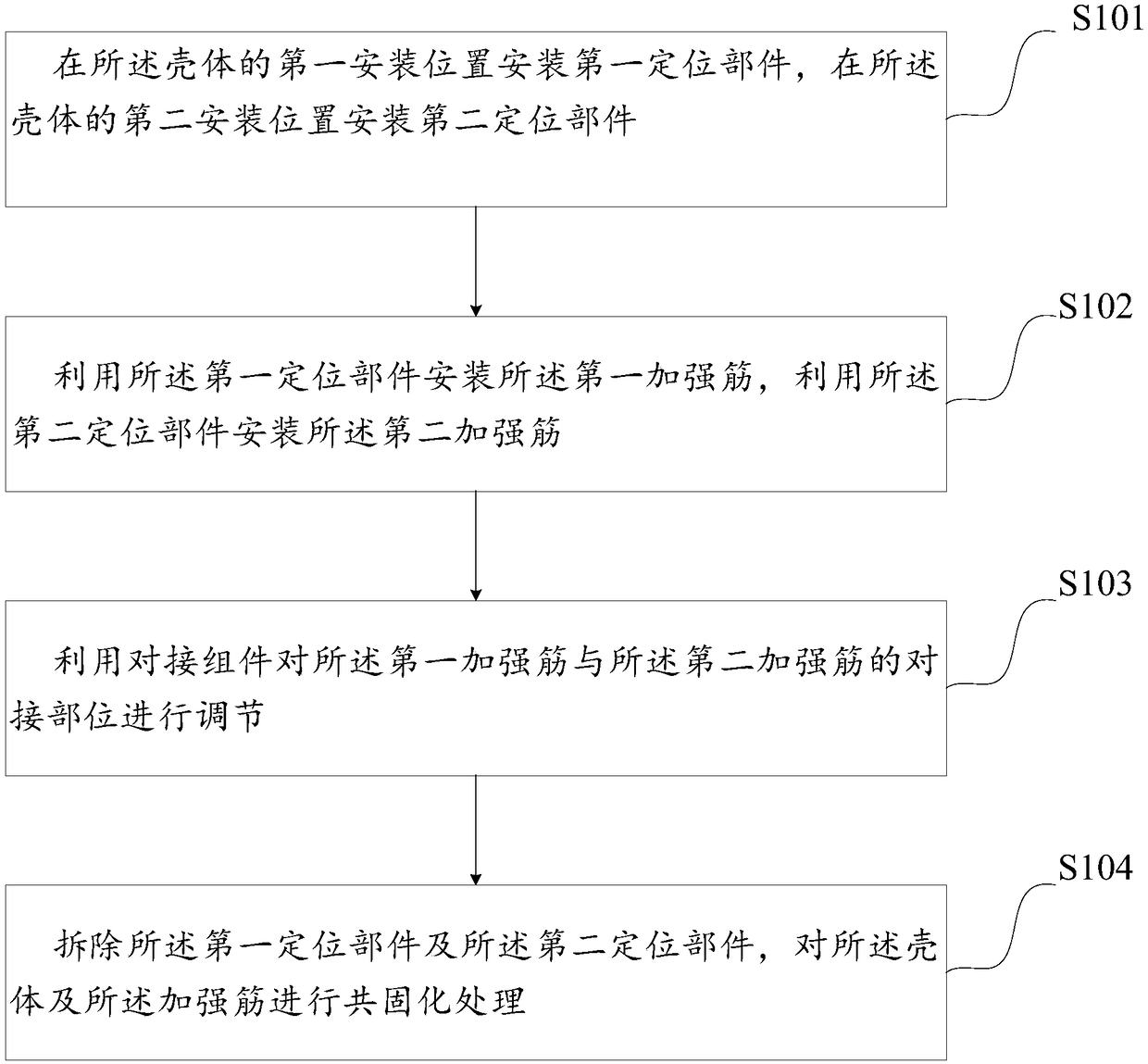

A method for forming inner circumferential reinforcing ribs of a composite material shell

A technology for hoop stiffeners and composite materials is applied in the field of forming hoop stiffeners in composite material shells, which can solve the problems of easy falling off, inability to ensure the quality of the bonding interface, and inaccurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0054] In practical applications, when the circumferential reinforcement ribs of the composite shell are formed by the method provided in the first embodiment, the details are as follows:

[0055] Installing a first positioning component at the first position of the housing, and before installing a second positioning component at the second position of the housing, the method further includes: laying a prepreg in the housing forming mold After the mold is closed, the shell is preformed at a temperature of 110°C. The two ends of the shell molding die are provided with metal baffles, and the two ends of the baffles are respectively provided with assembly holes of the first positioning component and the second positioning component for installation at the first position of the shell The first positioning component is installed at the second position of the housing. Wherein, the first position of the shell is one side of the axis of the hoop stiffener, and the second position of the...

Embodiment 3

[0069] In actual applications, when using the method provided in the first embodiment to shape the circumferential stiffeners of another composite shell, the details are as follows:

[0070] Installing a first positioning component at the first position of the housing, and before installing a second positioning component at the second position of the housing, the method further includes: laying a prepreg in the housing forming mold After the mold is closed, the shell is preformed at a temperature of 120°C. The two ends of the shell molding die are provided with metal baffles, and the two ends of the baffles are respectively provided with assembly holes of the first positioning component and the second positioning component for installation at the first position of the shell The first positioning component is installed at the second position of the housing. Wherein, the first position of the shell is one side of the axis of the hoop stiffener, and the second position of the shell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com