Preparation method of insulated silica gel belts

A silicone tape and silicone technology, applied in flat products, other household appliances, household appliances, etc., can solve problems such as waste, achieve high production efficiency, save mold costs, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

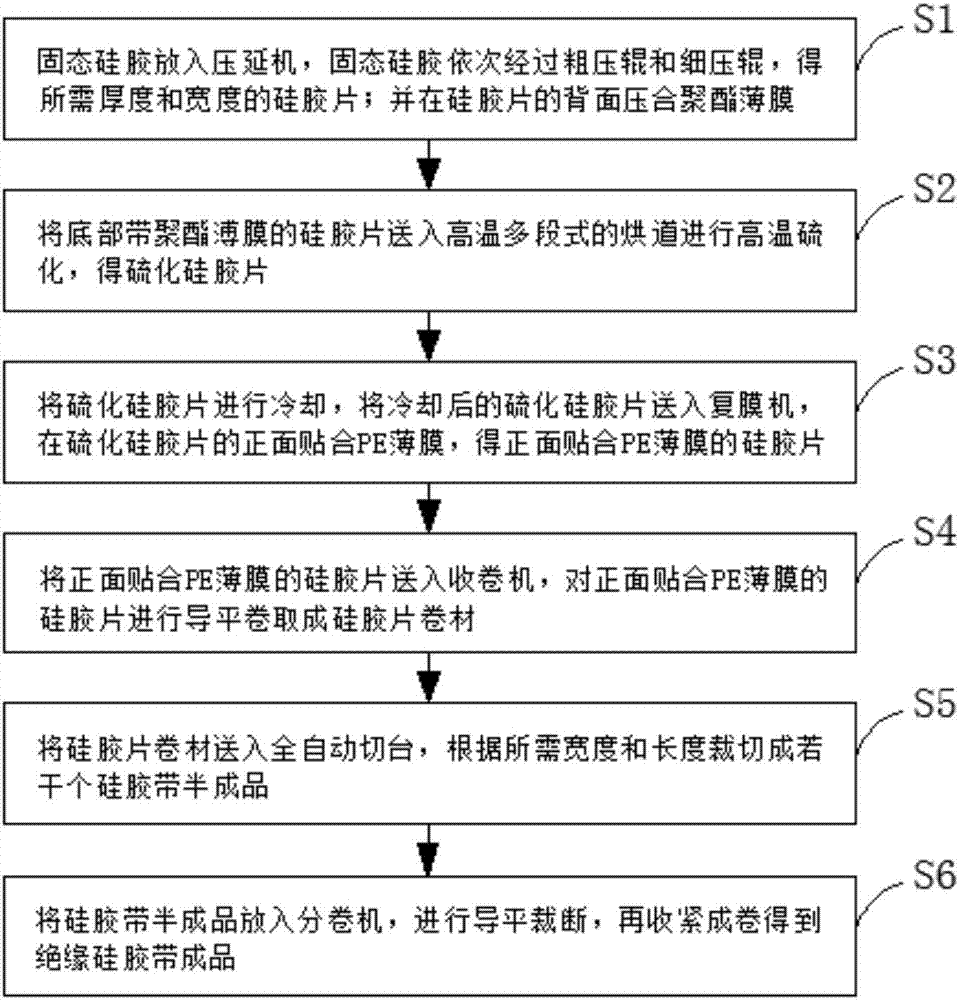

[0027] Such as figure 1 Shown, a kind of preparation method of insulating silicone tape, comprises the following steps:

[0028] Step S1. The solid silica gel is put into the calender, and the solid silica gel passes through the rough pressing roller and the fine pressing roller in turn to obtain a silica gel sheet with a width of 500 mm and a thickness of 0.25 mm; and laminate a polyester film on the back of the silica gel sheet;

[0029] Step S2. Send the silica gel sheet with polyester film on the bottom into a high-temperature eight-stage drying tunnel for high-temperature vulcanization, and the drying tunnel performs eight-stage high-temperature vulcanization on the silica gel sheet with polyester film on the bottom; wherein the first high-temperature vulcanization The temperature of the stage is: 130°C; the temperature of the second high-temperature vulcanization stage is: 130°C; the temperature of the third high-temperature vulcanization stage is: 120°C; the temperature...

Embodiment 2

[0036] A preparation method for an insulating silicone tape, comprising the following steps:

[0037] Step S1. The solid silica gel is put into the calender, and the solid silica gel passes through the rough pressing roller and the fine pressing roller in turn to obtain a silica gel sheet with a width of 800 mm and a thickness of 0.8 mm; and laminate a polyester film on the back of the silica gel sheet;

[0038] Step S2. Send the silica gel sheet with polyester film on the bottom into a high-temperature eight-stage drying tunnel for high-temperature vulcanization, and the drying tunnel performs eight-stage high-temperature vulcanization on the silica gel sheet with polyester film on the bottom; wherein the first high-temperature vulcanization The temperature of the stage is: 135°C; the temperature of the second high-temperature vulcanization stage is: 135°C; the temperature of the third high-temperature vulcanization stage is: 125°C; the temperature of the fourth high-temperatu...

Embodiment 3

[0045] A preparation method for an insulating silicone tape, comprising the following steps:

[0046] Step S1. The solid silica gel is put into the calender, and the solid silica gel passes through the rough pressing roller and the fine pressing roller in sequence to obtain a silica gel sheet with a width of 1200 mm and a thickness of 1.5 mm; and laminate a polyester film on the back of the silica gel sheet;

[0047]Step S2. Send the silica gel sheet with polyester film on the bottom into a high-temperature eight-stage drying tunnel for high-temperature vulcanization, and the drying tunnel performs eight-stage high-temperature vulcanization on the silica gel sheet with polyester film on the bottom; wherein the first high-temperature vulcanization The temperature of the stage is: 140°C; the temperature of the second high-temperature vulcanization stage is: 140°C; the temperature of the third high-temperature vulcanization stage is: 130°C; the temperature of the fourth high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com