Dry hanging stone keel

A dry-hanging stone and keel technology, which is applied to building components, walls, buildings, etc., can solve problems such as difficulty in ensuring the flatness of keels, time-consuming and labor-intensive installation, and difficult adjustment of keels, achieving great practical and promotional value, convenient use and installation, fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

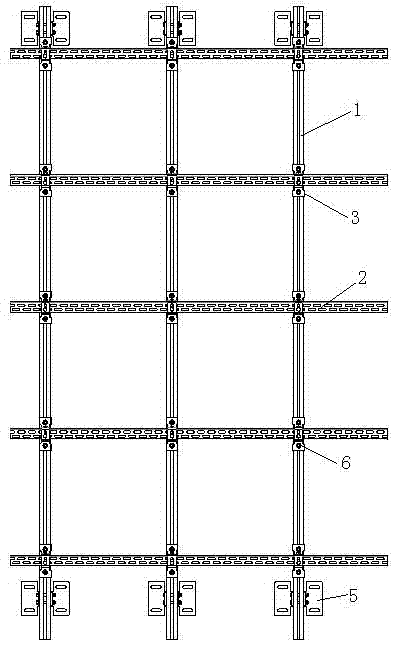

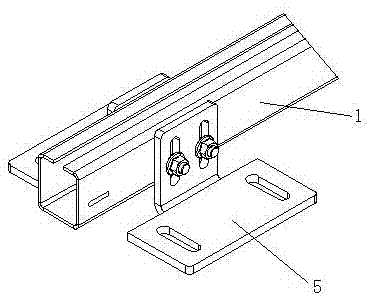

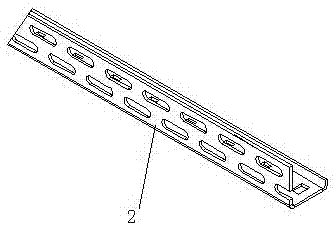

[0019] Reference attached figure 1 , Attached figure 2 , Attached image 3 , Attached Figure 4 , Attached Figure 5 , Attached Image 6 , The dry hanging stone keel of the present invention is composed of a main keel 1, a secondary keel 2, a transitional connecting piece 3, a connecting pin 4, a wall connecting piece 5, and a connecting bolt 6. The main keel 1 passes through the wall connecting piece 5 Vertically fixed on the wall; the connecting bolt 6 is set on the main keel 1 and the auxiliary keel 2 is laterally fastened to the main keel 1 through the transition connecting piece 3; the connecting pin 4 is set on the main keel 1 The inner part is used for the extension connection of the main keel 1; the stone is set on the auxiliary keel 2 through the pendant; the main keel 1 adopts the structural form of the steel belt integrally rolled into channel steel; the auxiliary keel 2 body is folded by the steel belt into two plates perpendicular to each other Integral angle ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com