AMT transmission gear-shifting meshing point position self-learning method

A self-learning method and meshing point technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as reduced efficiency, increased cost, weak starting and climbing power, etc., to achieve guaranteed Smoothness, the effect of eliminating the deviation of the meshing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

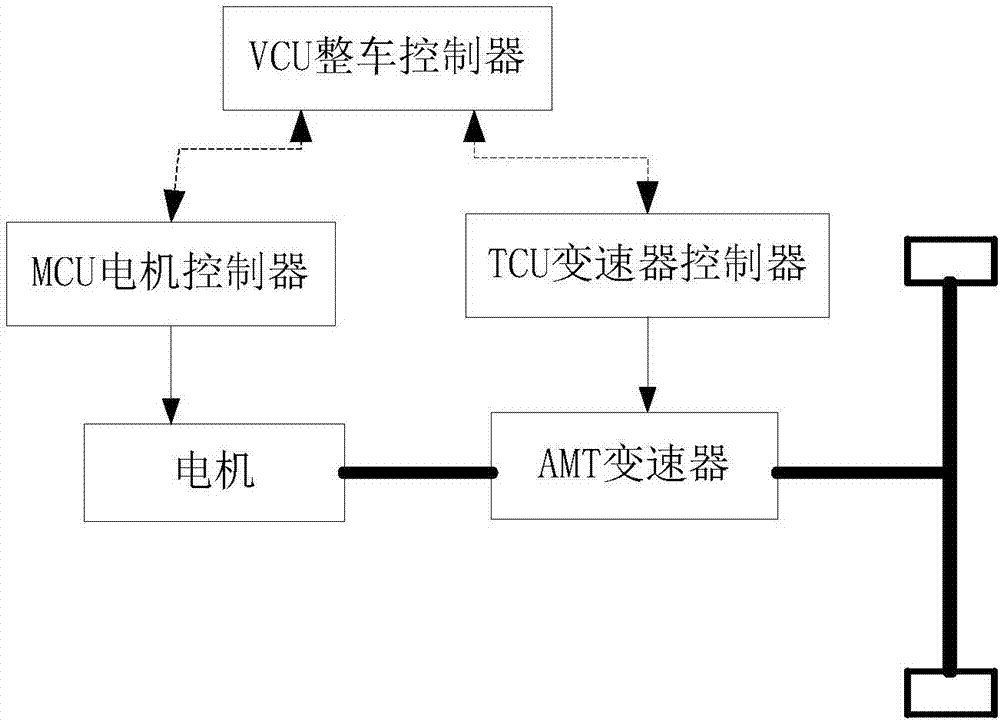

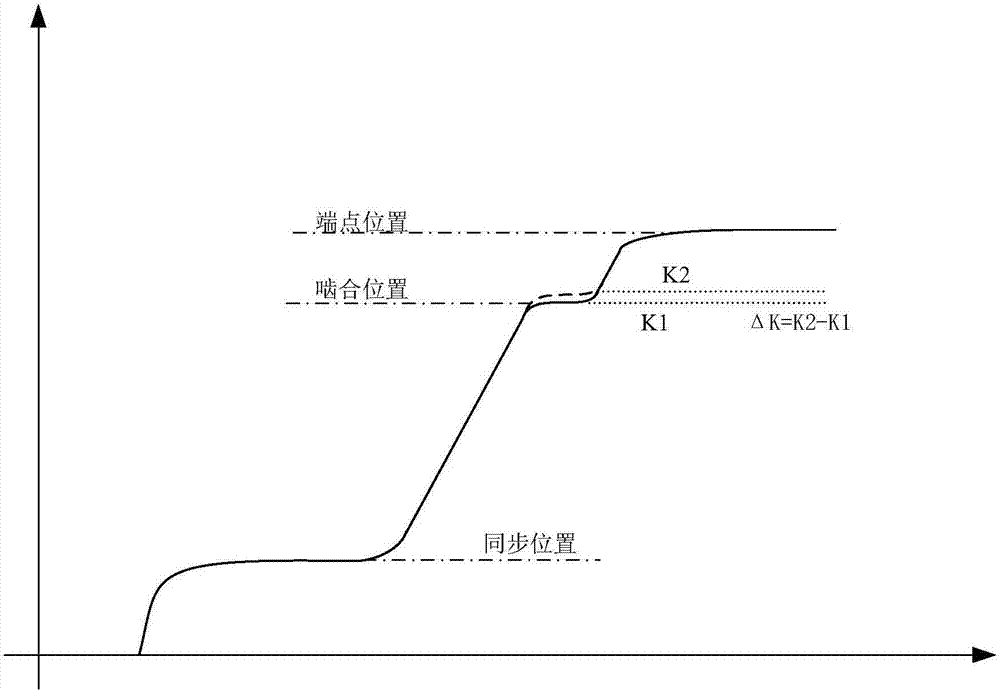

[0029] This embodiment provides a self-learning method for the position of the shifting mesh point of an AMT transmission, which is applied to a system composed of a motor + a mechanical automatic transmission. There is a synchronizer in this system, but there is no clutch separation mechanism, and the MCU motor controller The torque and speed control of the motor is realized. The VCU vehicle controller collects information such as the accelerator and brake of the vehicle, calculates the required torque of the vehicle, and realizes the coordinated control of the vehicle. The TCU transmission controller calculates the required gear based on the information of the accelerator and vehicle speed. And complete the gear shifting operation through the gear shift actuator (electric actuator or hydraulic actuator). In this embodiment, the structure of the system is as follows figure 1 shown.

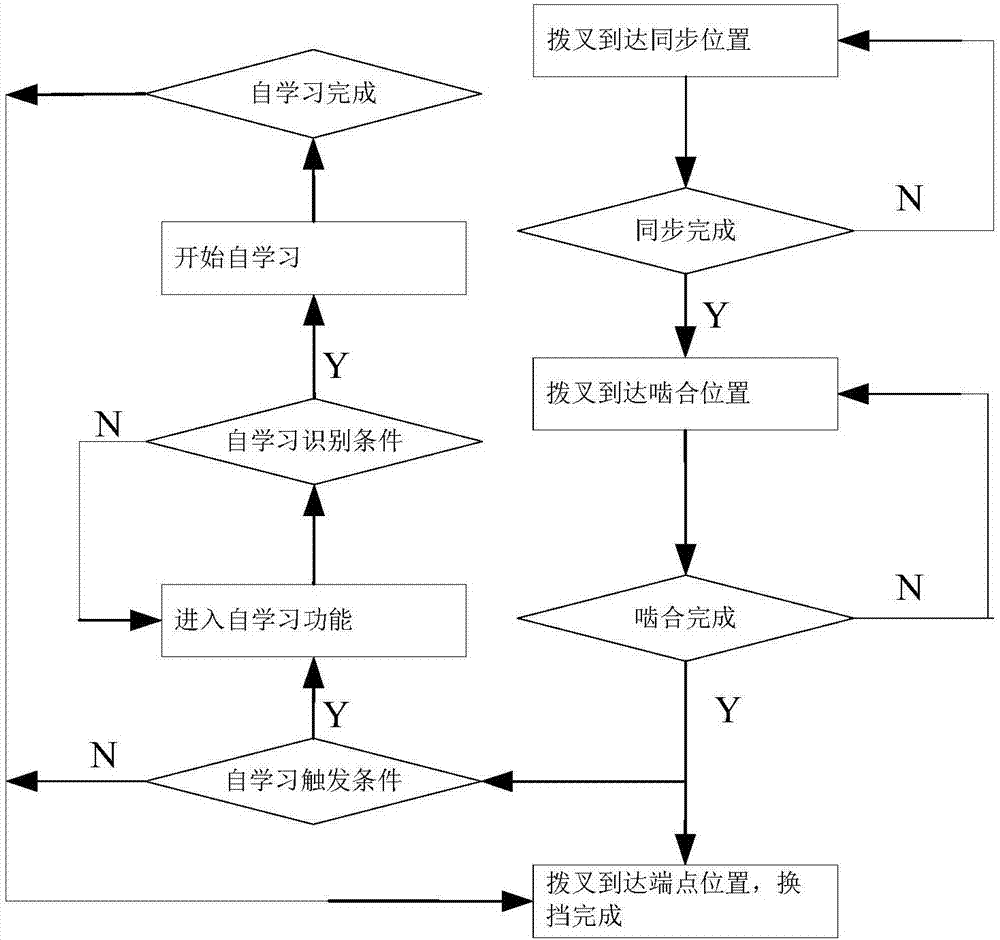

[0030] The methods include:

[0031] S10. The TCU transmission controller judges the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com