Ultimate bearing capacity analysis method for steel pressure vessel based on yield strength and tensile strength double key points

A technology of ultimate bearing capacity and yield strength, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as inconvenient engineering application, complicated calculation process, and strict requirements for calculation parameters, and achieve good calculation accuracy and practicality. The effect of the convenience solution method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

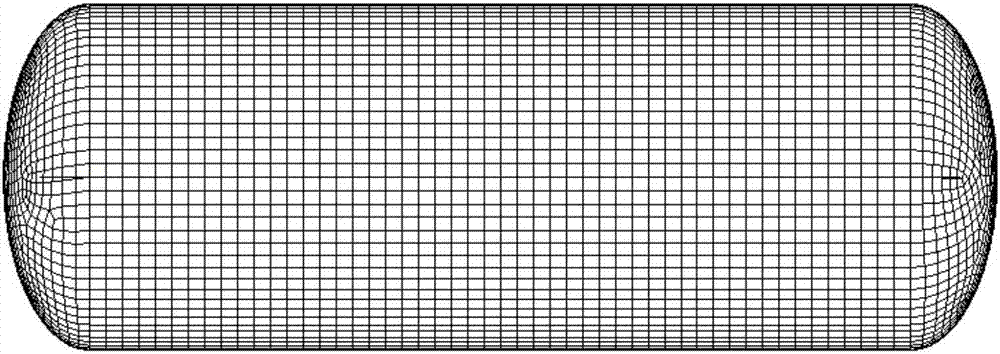

[0025] This embodiment is a specific example of an analysis method for the ultimate bearing capacity of a steel pressure vessel based on the double key points of yield strength and tensile strength, including the following steps:

[0026] (1) Obtain the geometric parameters, elastic modulus and double key point parameters of the pressure vessel:

[0027] The geometric parameters and elastic modulus of a pressure vessel are shown in Table 1, and the parameters of double key points are shown in Table 2.

[0028] Table 1 Geometric parameters and modulus of elasticity

[0029]

[0030] Table 2 Double key point parameters

[0031] Double Keypoint Parameters Yield Strength tensile strength value 324.00MPa 460.00MPa

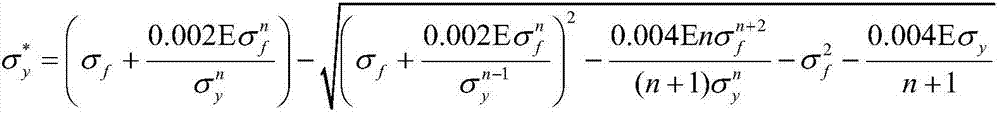

[0032] (2) Solve the equivalent yield strength based on double key points

[0033] Based on the double key point parameters obtained in step (1), calculate the equivalent yield strength:

[0034]

[0035] Among them, the hardening in...

Embodiment 2

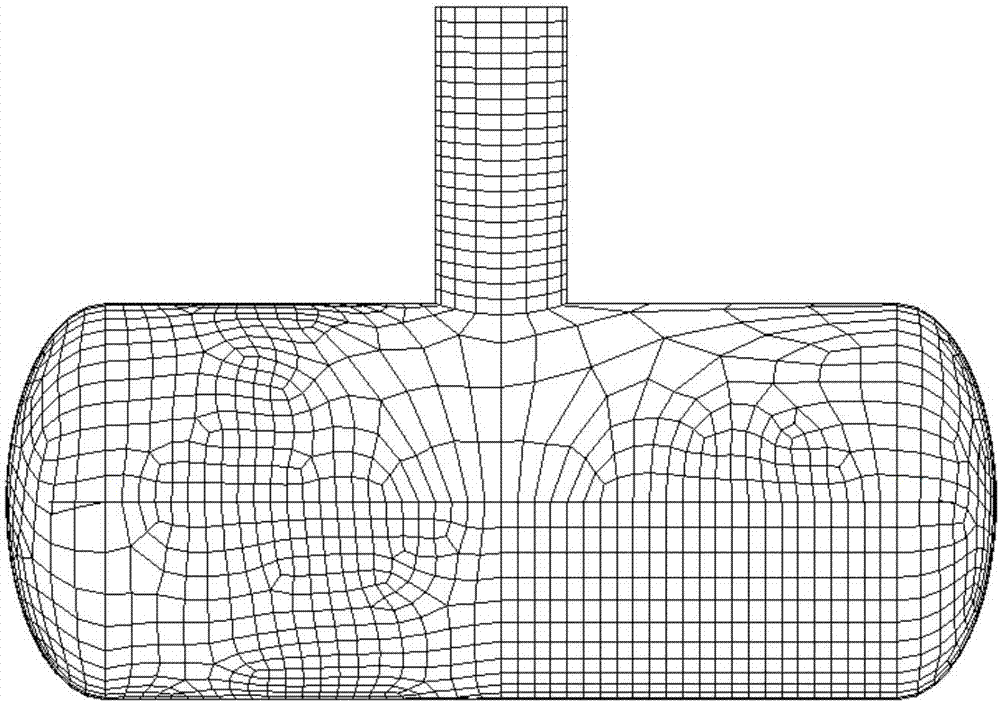

[0045] This embodiment is another specific example of the ultimate bearing capacity of a steel pressure vessel based on the double key points of yield strength and tensile strength, including the following steps:

[0046] (1) Obtain the geometric parameters, elastic modulus and double key point parameters of the pressure vessel:

[0047] The barrel and connecting pipe of a pressure vessel are made of different materials. The geometric parameters and elastic modulus of the barrel are shown in Table 4, the double key point parameters of the barrel are shown in Table 5, and the geometric parameters and elastic modulus of the connecting pipe are shown in Table 4. 6, and the double keypoint parameters of the takeover are shown in Table 7.

[0048] Table 4 geometric parameters and modulus of elasticity of the cylinder

[0049]

[0050] Table 5 Double key point parameters of cylinder

[0051] Double Keypoint Parameters Yield Strength tensile strength value 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate bearing capacity | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com