Foaming mold of foaming multi-slide-block following mechanism box body with beam

A technology of a follow-up mechanism and a foaming mold, applied in the field of molds, can solve the problems of inconvenient assembly, disassembly and maintenance, difficult application of the expansion and contraction mechanism, and difficulty in cleaning the mechanism, so as to shorten the production cycle, save time and labor in use and maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

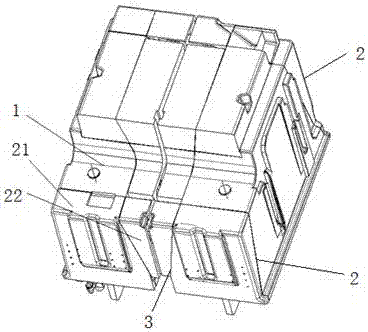

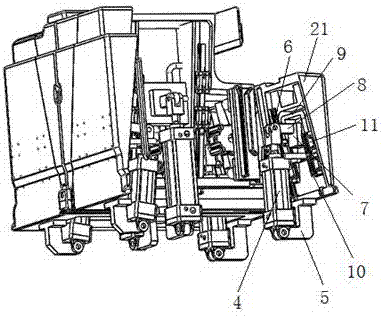

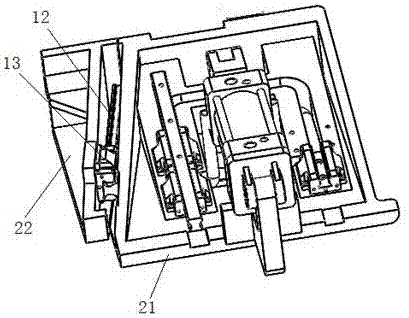

[0023] see figure 1 , a beam foaming multi-slider follower mechanism box foaming mold provided by the present invention includes a mold shell 1, the front side and the rear side of the mold shell 1 are provided with a shell mouth and a cover to cover the shell mouth The slider group 2, the slider group 2 includes active sliders 21 located on both sides of the shell mouth, and a follower slider 22 that is restricted by the two drive sliders 21 to move down, and the outer wall of the follower slider 22 is slidably fitted on the On the inner side wall of the active slider 21 , a mechanical component for pushing the active slider 21 to slide is provided in the mold housing 1 .

[0024] After the foaming is completed, the foamed product (the following example is the refrigerator liner, not shown in the figure) is covered on the mold. At this time, the mechanical component pushes the active slider 21, and the active slider 21 moves downward. When the active slider When block 21 tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com