Following filling mechanism of full-automatic following filling machine

A filling machine, fully automatic technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of high equipment cost, affecting production efficiency, and multiple production spaces, so as to avoid pinching the bottle mouth and increase production efficiency , The effect of reducing the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

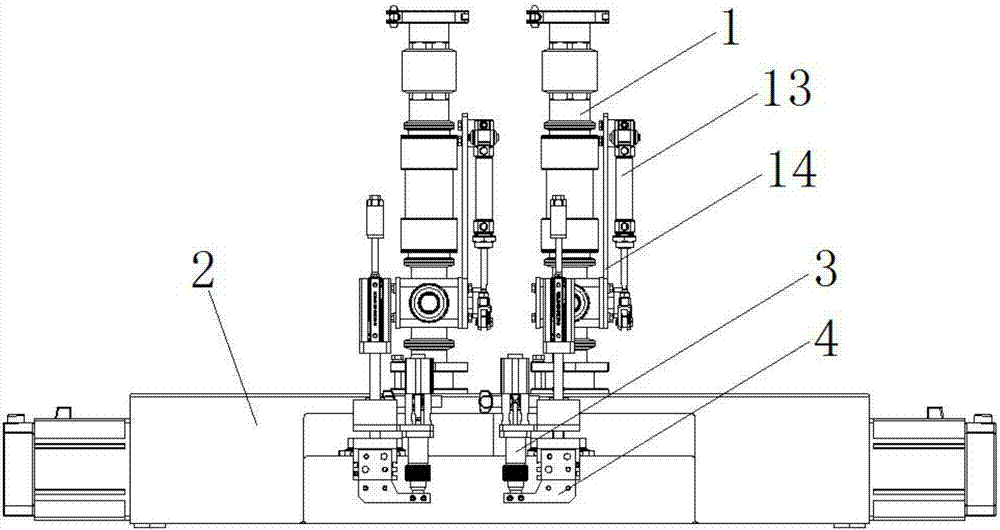

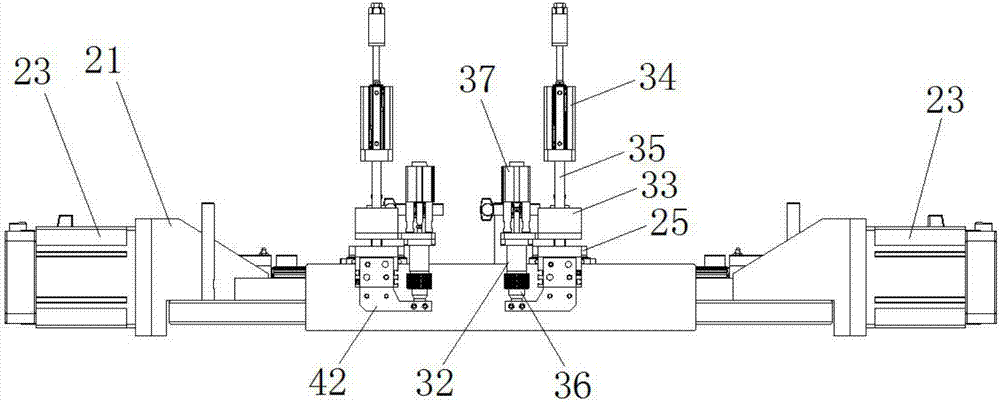

[0031] See figure 1 , the follow-up filling mechanism of the fully automatic follow-up filling machine in this embodiment includes a feeding device 1 , a traverse follower device 2 , a filling device 3 and a bottle clamping device 4 .

[0032] The feeding device 1, the filling device 3 and the bottle clamping device 4 are all provided with two groups. 4 above. The traverse follower 2 drives two groups of filling devices 3 and two groups of bottle clamping devices 4 to move in the horizontal direction.

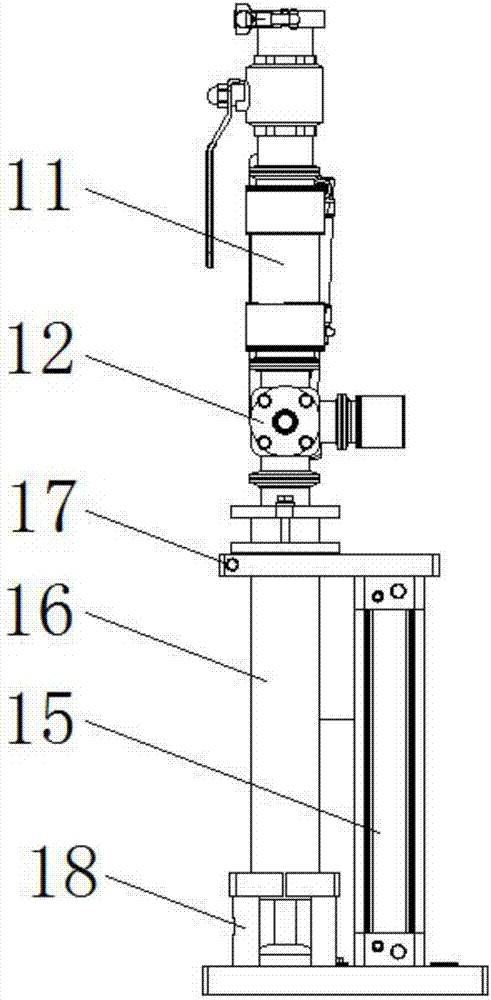

[0033] The feeding device 1 comprises a feeding pipe 11, a feeding valve 12, a valve control cylinder 13, a cylinder support plate 14, a feeding lifting cylinder 15, a lifting guide rod 16, a lifting plate 17 and a guide seat 18. The inlet of the feeding valve 12 is communicated with and fixed to the bottom of the feeding pipe 11 , and the outlet of the feeding valve 12 is connected to the filling device 3 . Cylinder support plate 14 is fixed on the shell of feeding valve 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com