Tree defect detection device and detection method

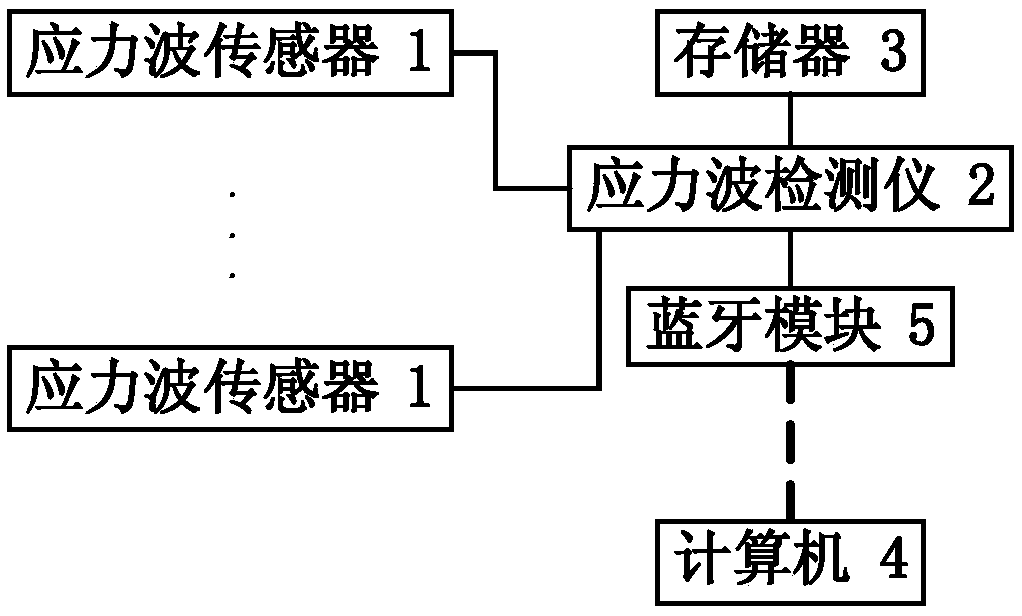

A defect detection and detection method technology, which is applied in measuring devices, instruments, analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as inability to accurately detect internal defects in wood and incomplete detection methods, and achieve strong promotion and application. Value, suitable for promotion, high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

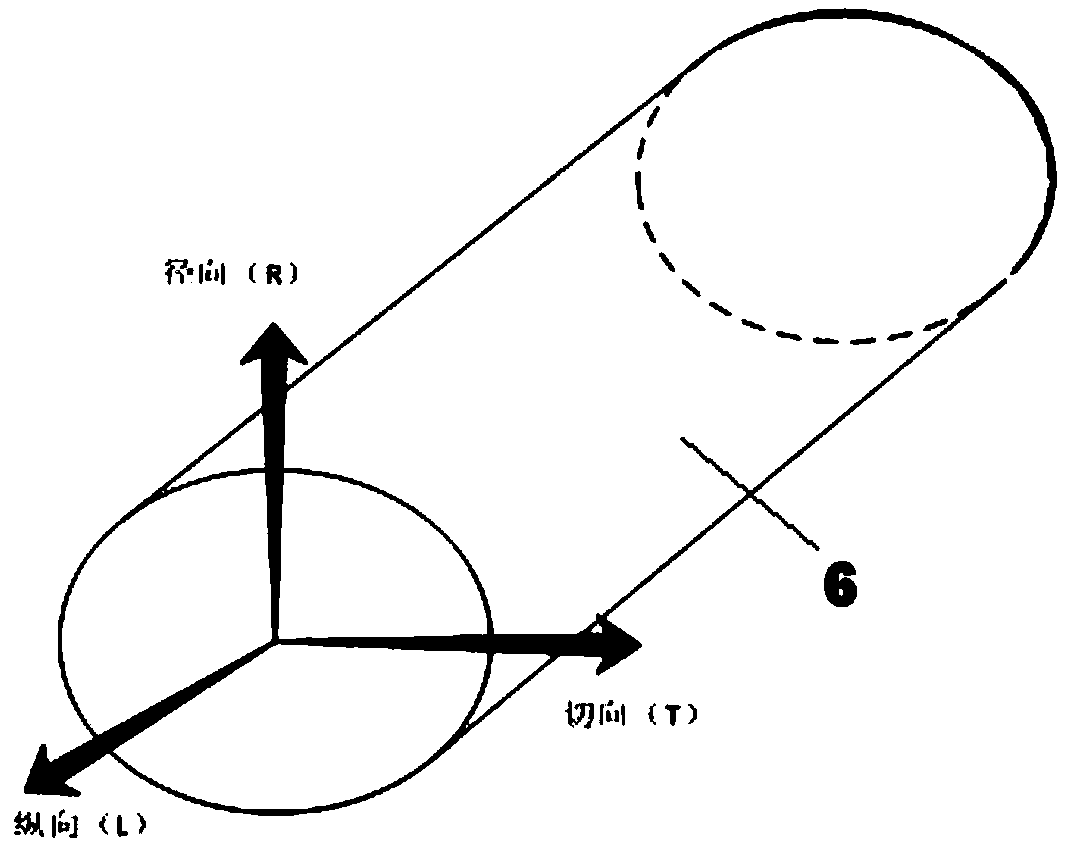

[0069] The experiment uses such as image 3 As shown in the cedar, a longitudinal section with an angle of 15° to the radial section is detected, and 6 stress wave sensors are arranged on both sides of the section. The distance between each sensor on one side is 10cm, and the sensor numbers are 1-12;

[0070] During the experiment, a pulse hammer was used to strike from No. 1 to No. 12 in sequence, and the propagation time of the stress wave between each sensor was recorded. Six longitudinal sections with different angles α, including the radial section, were tested in a single experiment. The included angles α are 0°, 15°, 30°, 45°, 60°, and 75°, respectively. By analyzing the stress wave propagation velocity on the longitudinal section of six different section angles α, we can know the internal defects of wood in the longitudinal direction, such as defect position, size and shape. The specific experimental steps are as follows:

[0071] Step 1: Carry out 6 times of fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com