Cable detection board, cable detection method, and line sequence, impedance, insulation and aging detection methods

A detection board, insulation technology, applied in the direction of measuring resistance/reactance/impedance, measuring electricity, measuring devices, etc., can solve the problems of easy errors and omissions, difficult operation, complicated wiring, etc., to reduce costs and wide range of applications , the effect of reducing wiring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

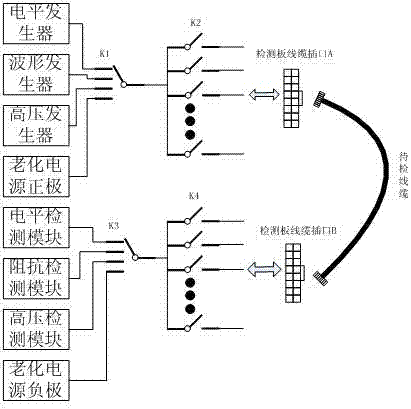

[0026] Such as figure 1As shown, the level generator, the waveform generator, the high voltage generator, and the positive electrode of the aging power supply are respectively connected to the four selection terminals of the first function selection switch K1. The common end of the first function selector switch is connected with eight first detection switches K2, and each first detection switch is respectively connected to one end of the eight-core wire to be detected by the first socket A. The other end of the wire to be tested is correspondingly connected to the eight second detection switches K4 through the second socket B. The other end of the second detection switch is connected together and then connected with the common end of the second function selection switch K3; Negative connection.

[0027] Insulation requirements for cable processing to be inspected: 5 megohms, 1000V; on-resistance less than 5 ohms; aging requirements: 2A for 1 hour; high level is defined as 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com