Novel logistics shelf

A logistics and shelf technology, applied in the field of new logistics shelves, can solve the problems of inability to absorb shock protection, waste space, affect the performance and scope of application of logistics shelves, etc., and achieve the effect of flexible structure adjustment and good shock absorption and buffering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

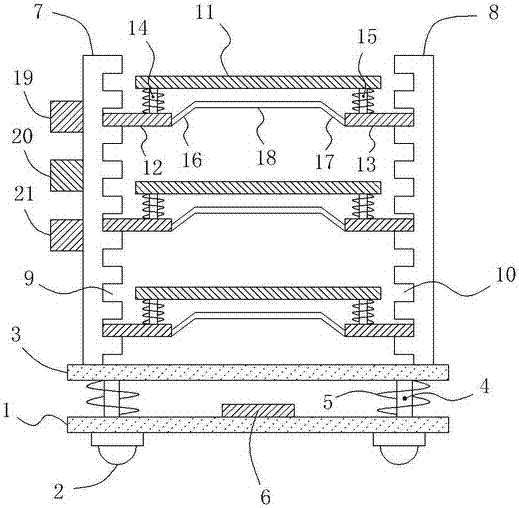

[0013] Such as figure 1 As shown, a new type of logistics shelf includes a base 1 and a universal wheel 2 located at the bottom of the base 1. A support plate 3 parallel to the base 1 is also provided above the base 1. Between the support plate 3 and the base 1 A plurality of vertically arranged bottom telescopic rods 4 are connected, and a bottom coil spring 5 is sheathed outside the bottom telescopic rods 4 to achieve good shock absorption and buffering. At the same time, a limit block 6 is also provided on the base 1; The top left end and the top right end of the support plate 3 are respectively vertically provided with a left vertical board 7 and a right vertical board 8, and a plurality of left strip-shaped grooves 9 are evenly opened from top to bottom on the right side plane of the left vertical board 7. The left plane of the right vertical plate 8 is uniformly provided with a plurality of right bar-shaped grooves 10 corresponding to the left bar-shaped groove 9 from to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com