A variable cross-section engine block suture bolt structure and its assembly process

A technology for engine body and stitching bolts, which is applied in the direction of engine components, machines/engines, bolts, etc., can solve the problems of vibration fatigue fracture, vibration load, etc., and achieve the effect of increasing the natural frequency of vibration, improving reliability, and reliable stitching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

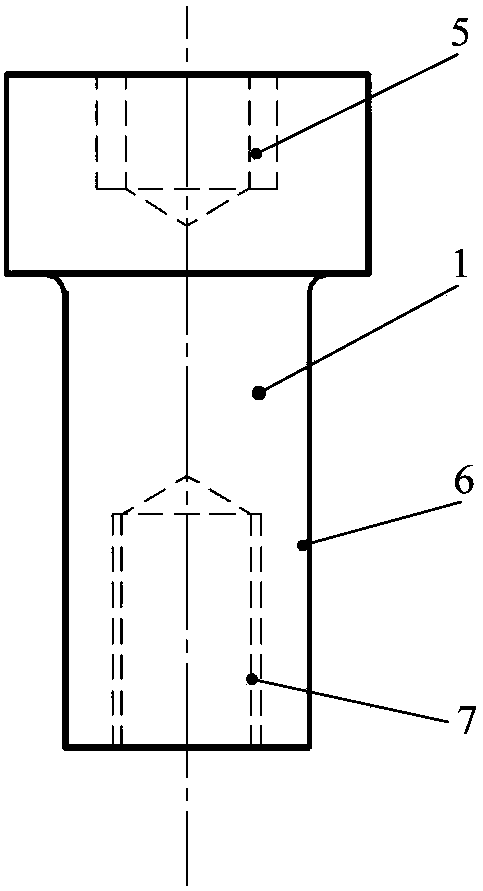

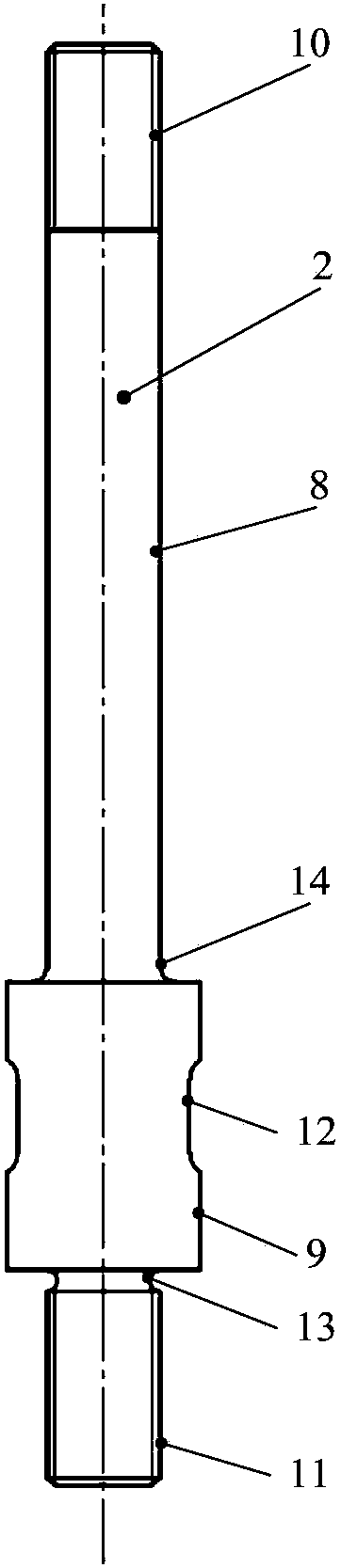

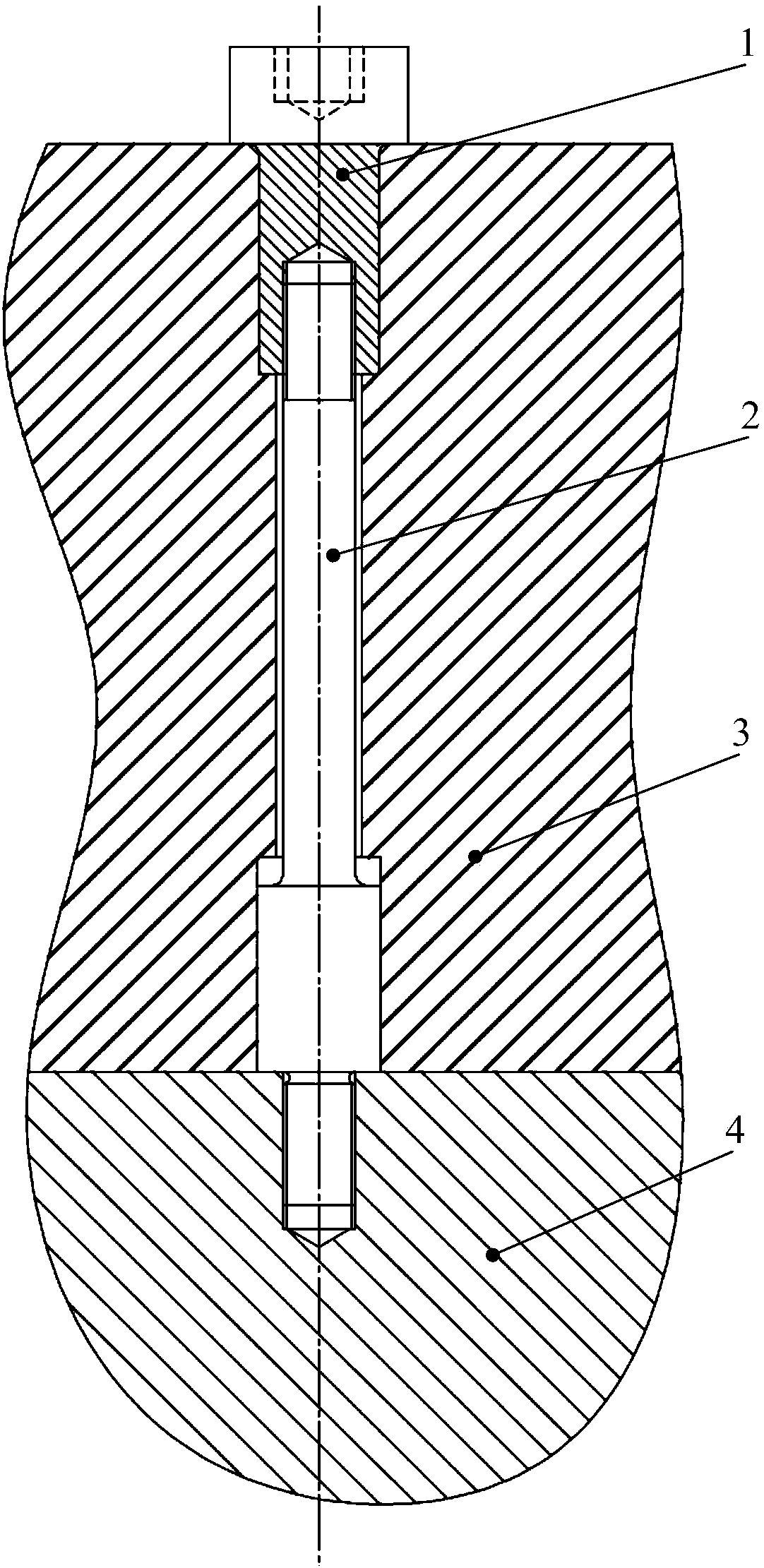

[0033] A suture bolt structure for a variable-section engine body, comprising a bolt locking sleeve 1, a variable-section screw rod 2, an upper crankcase 3 and a lower crankcase 4. There is an inner hexagonal nut 5 used during assembly and disassembly at one end of the top of the bolt locking sleeve 1, and the optical axis 6 assembled with the upper crankcase 3 is arranged on the bolt locking sleeve 1, and the bolt locking sleeve 1 On the optical axis of 1, there is a threaded blind hole 7 assembled with the upper external thread 10 of the variable cross-section screw rod 2, such as figure 1 As shown; one end of the variable cross-section screw 2 has an upper external thread 10 assembled with the threaded blind hole 7 of the bolt locking sleeve 1, and the other end of the variable cross-section screw 2 has a threaded hole corresponding to the lower crankcase 4. Assembled lower external thread 11, the middle part of the variable cross-section screw 2 is two small diameter polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com