Plastic intake manifold detection tool

An intake manifold and plastic technology, applied in the field of plastic intake manifold inspection tools, can solve the problems of low production efficiency, cumbersome operation, prolonged inspection cycle, etc., so as to improve production efficiency, simplify operation procedures, and reduce inspection tooling costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

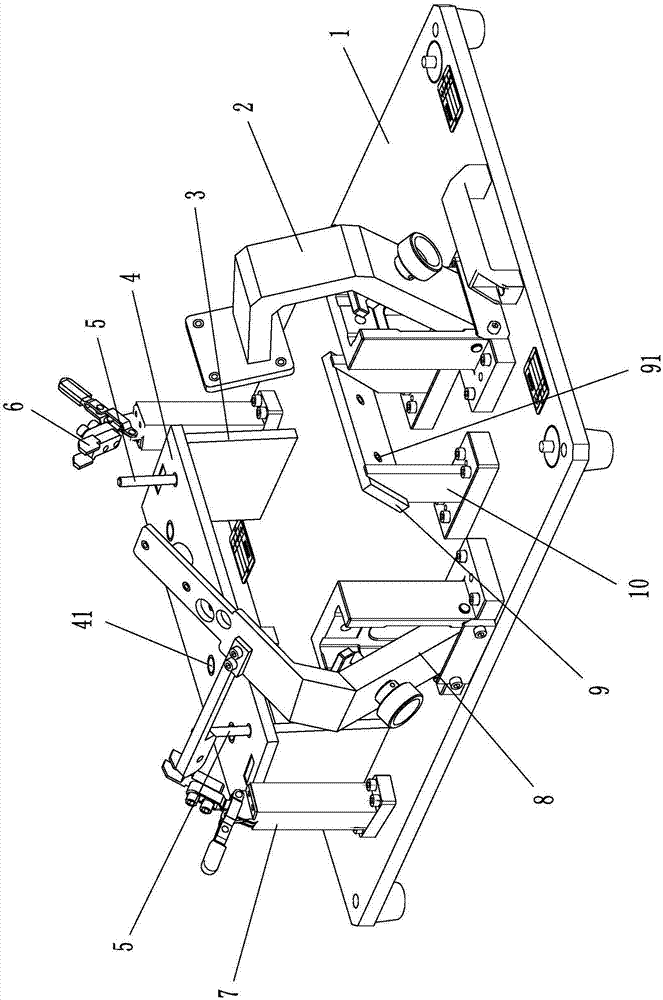

[0024] Embodiment 1: A kind of inspection tool for plastic intake manifold, such as Figure 1-Figure 3 As shown, it includes base 1, detection mechanism I2, support plate I3, main positioning plate 4, clamping mechanism I6, clamping mechanism II7, detection mechanism II8, inclined positioning plate 9 and support plate II10.

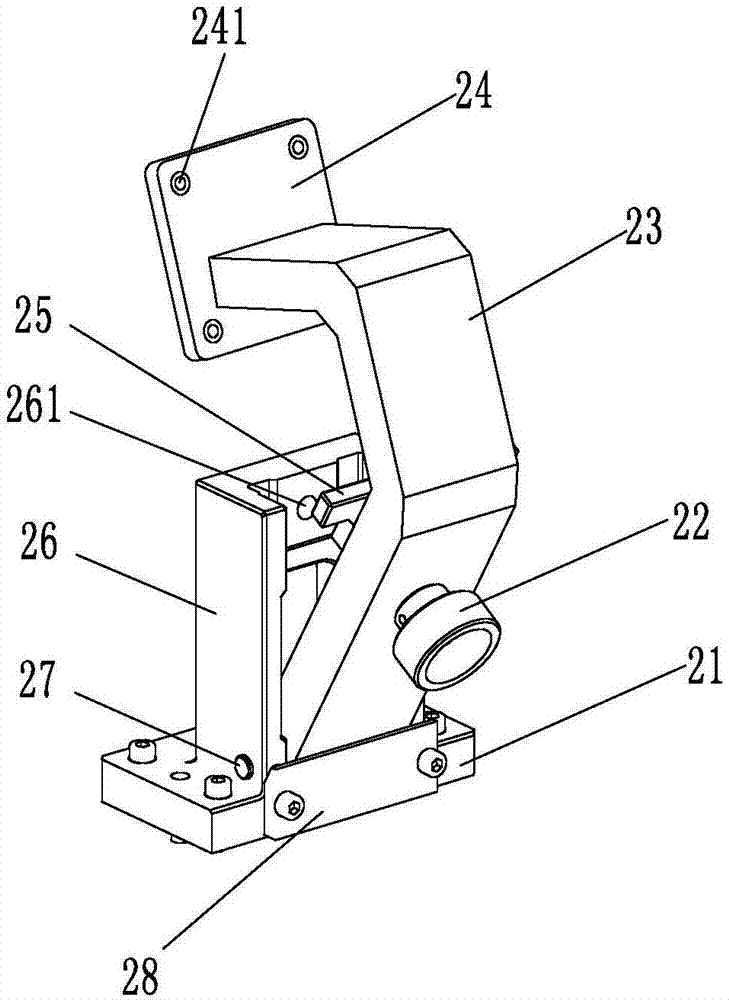

[0025] The detection mechanism I2 includes a detection seat I21, a detection bracket I23, a composite detection block I24, a vertical positioning block I26 and a flip pin I27. The vertical positioning block I26 is installed on the detection seat I21, and the bottom end of the detection bracket I23 Installed in the vertical positioning block I through the flip pin I27, the bottom end of the vertical positioning block I is installed with a limit plate I28 for limiting the flip angle of the detection bracket I, and the composite detection block I24 is installed on the top of the detection bracket I23, There is a detection pin hole I 241 for detecting the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com