Automatic feeding machine for pig breeding

A feeder, automatic technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of easy mildew of leftover materials, loss of producers, uneven feeding, etc., to reduce labor intensity of workers, reduce Feed wastage and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

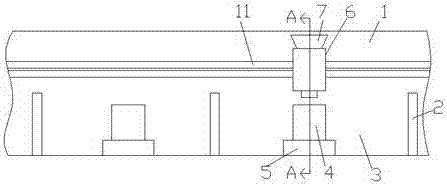

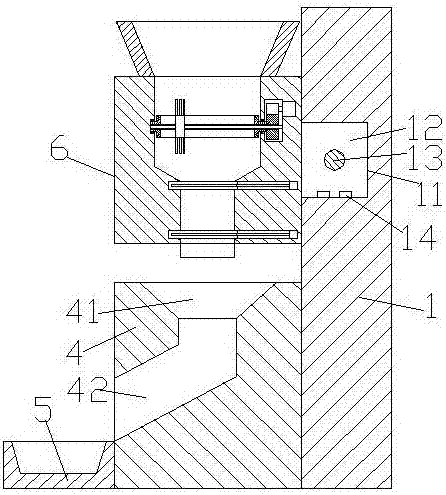

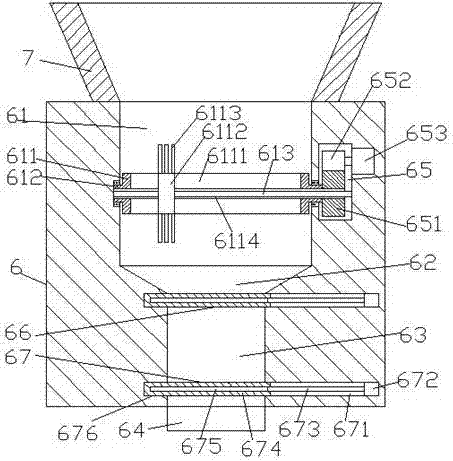

[0022] Such as Figure 1-Figure 4 As shown, a kind of automatic feeder for pig breeding of the present invention comprises an enclosure wall 1 provided with a chute 11 extending laterally, a moving block 12 slidingly fitted in the chute 11 and fixed on the chute 11. The feeding body 6 on the front end surface of the moving block 12, the top of the feeding body 6 is provided with a feeding hopper 7, and the inside of the feeding body 6 is sequentially provided with a first through cavity 61, a funnel-shaped cavity body 62 and a second through-cavity body 63, a drive chamber 65 is provided in the feeding body 6 on the rear side of the first through-cavity body 61, and a rotating roller extending forward and backward is provided in the first through-cavity body 61 611, the ends of the front and rear sides of the rotating roller 611 are provided with rotating shafts 612 respectively extending to the front and rear sides, and the extension of the rotating shaft 612 to the rear side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com