Quilted cushion and manufacturing method thereof

A cushioning and quilting technology, applied in the field of cushioning, can solve problems such as broken needles, damaged needles, and failure to produce normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

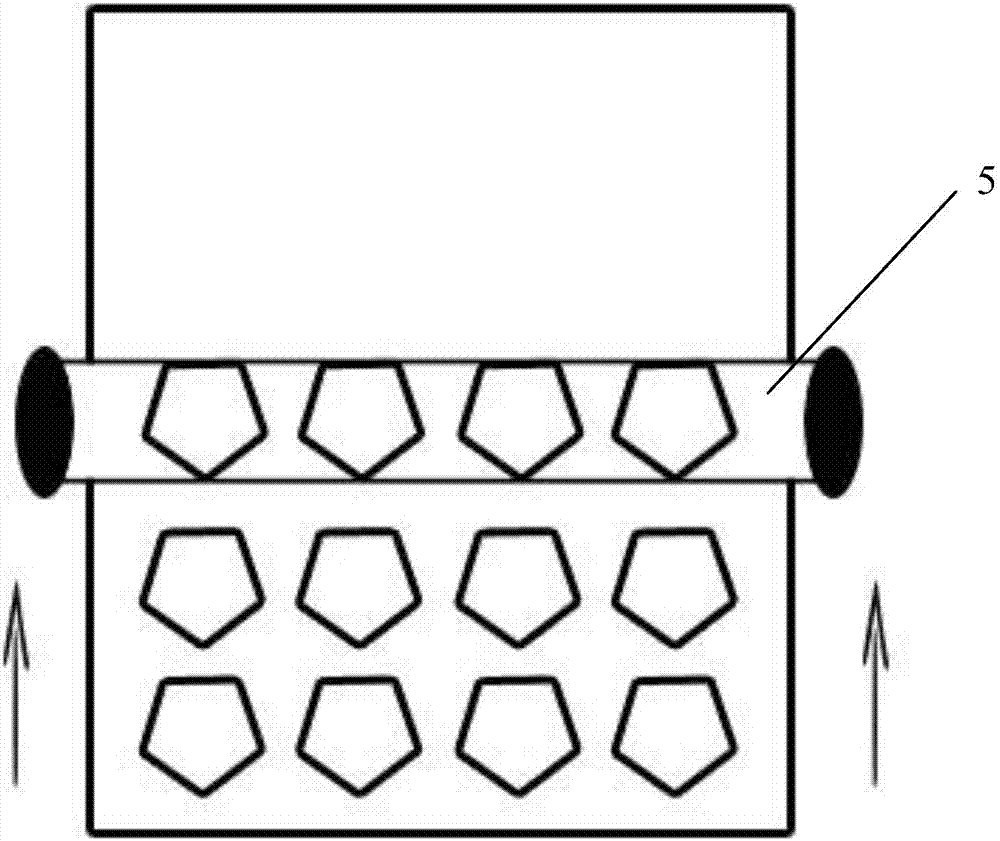

[0018] Such as Figure 1 to Figure 4 The quilted cushion shown includes a 3D warp-knitted spacer fabric layer, and the 3D warp-knitted spacer fabric layer is integrated with the fabric layer on the surface through ultrasonic high-temperature fusion bonding; the quilted cushion does not need to be sewn with needles and threads, There is also no need to use glue for bonding, so that the quilted cushion has the characteristics of three-dimensional beauty, continuous thread, no glue, environmental protection and non-toxicity, and the middle of the quilted cushion uses 3D warp-knitted spacer fabric made of polyester as the middle layer filling material , to ensure that the cushion is environmentally friendly, comfortable, breathable, and easy to clean. At the same time, ultrasonic bonding is used, so that the quilted cushion does not need to be stit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com