Laser etching appearance treatment process for notebook computer metal shell

A metal shell and laser etching technology, which is applied in metal processing, metal processing equipment, laser welding equipment, etc., can solve problems such as improper handling, non-wear-resistant transfer layer, and easy wear of the pattern on the metal, so as to achieve pattern unevenness Controllable depth, controllable surface roughness, rich appearance and style effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

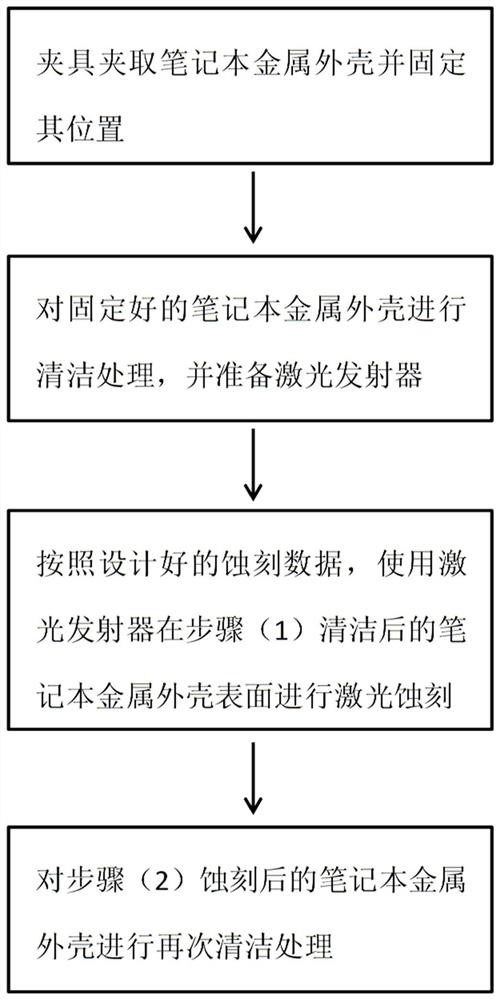

[0025] A laser etching appearance treatment process for a notebook metal casing, comprising the following steps:

[0026] (1) The fixture clamps the metal case of the notebook and fixes its position, then cleans the fixed metal case of the notebook and prepares the laser transmitter;

[0027] (2) According to the designed etching data, use a laser transmitter to perform laser etching on the surface of the notebook metal case cleaned in step (1). In the laser etching process, the laser transmitter is a green light source laser with a wavelength of 530nm and a power of 2.5 W, the frequency is 15KHz;

[0028] (3) Clean the metal casing of the notebook etched in step (2) again.

[0029] In this embodiment, the roughness of the surface pattern of the metal casing of the notebook obtained after laser etching is 0.05 μm, and the depth of the concavo-convex is 0.05 mm.

Embodiment 2

[0031] A laser etching appearance treatment process for a notebook metal casing, comprising the following steps:

[0032] (1) The fixture clamps the metal case of the notebook and fixes its position, then cleans the fixed metal case of the notebook and prepares the laser transmitter;

[0033] (2) According to the designed etching data, use a laser transmitter to perform laser etching on the surface of the notebook metal case cleaned in step (1). In the laser etching process, the laser transmitter is a UV violet light source laser with a wavelength of 350nm and a power of 3.5 W, the frequency is 17.5KHz;

[0034] (3) Clean the metal casing of the notebook etched in step (2) again.

[0035] In this embodiment, the roughness of the surface pattern of the metal casing of the notebook obtained after laser etching is 1 μm, and the depth of the concavo-convex is 0.2 mm.

Embodiment 3

[0037] A laser etching appearance treatment process for a notebook metal casing, comprising the following steps:

[0038] (1) The fixture clamps the metal case of the notebook and fixes its position, then cleans the fixed metal case of the notebook and prepares the laser transmitter;

[0039] (2) According to the designed etching data, use a laser transmitter to perform laser etching on the surface of the notebook metal case cleaned in step (1). In the laser etching process, the laser transmitter is a CO2 light source laser with a wavelength of 1600nm and a power of 4.5W. , the frequency is 20KHz;

[0040] (3) Clean the metal casing of the notebook etched in step (2) again.

[0041] In this embodiment, the roughness of the surface pattern of the metal casing of the notebook obtained after laser etching is 0.5 μm, and the depth of the concavo-convex is 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com