Preparation process of a double-needle bed jacquard flannel fabric with embossed effect

A technology of jacquard flannel and embossing effect, applied in the directions of knitting, warp knitting, textile and paper making, etc., can solve the problem of many restrictions on patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

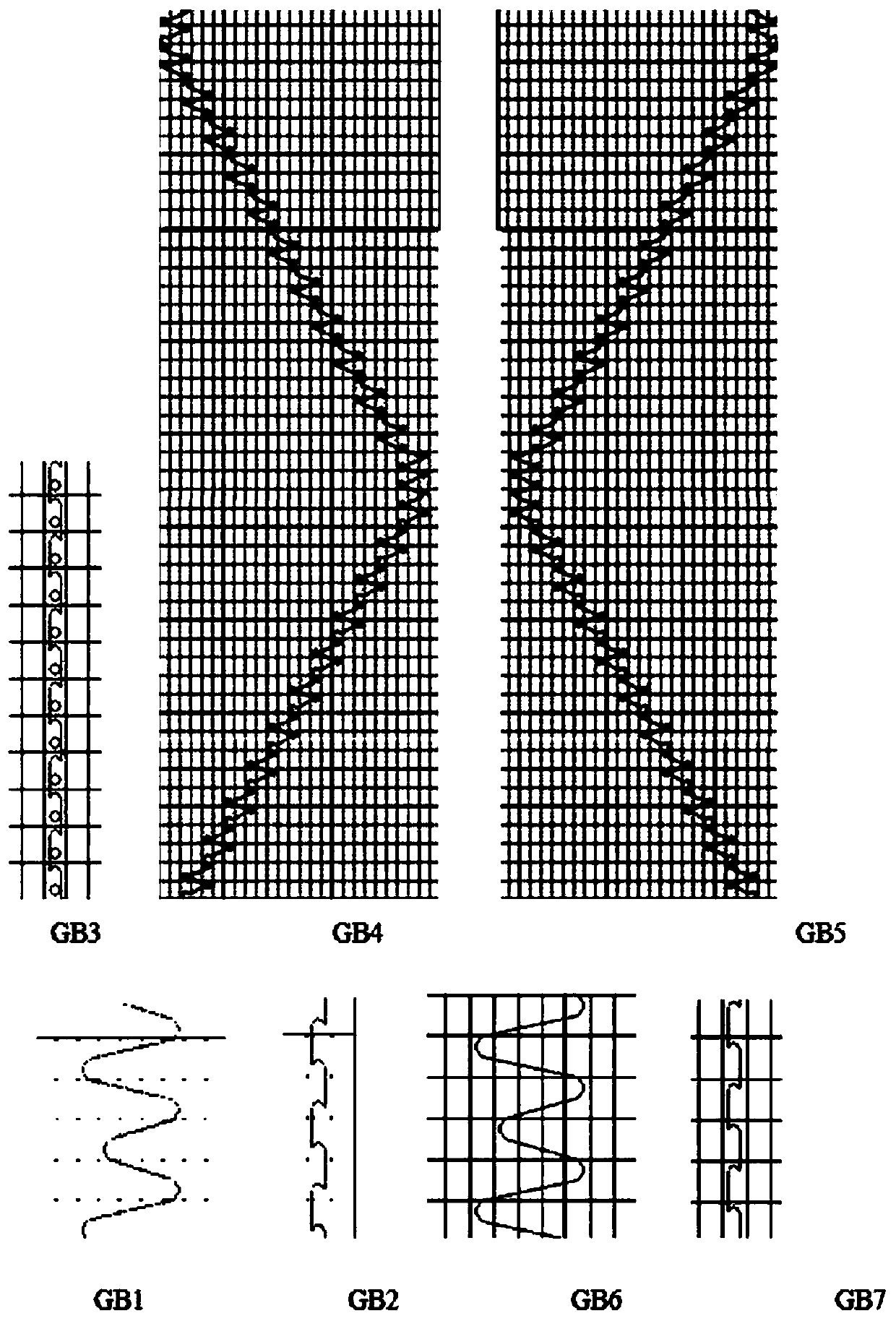

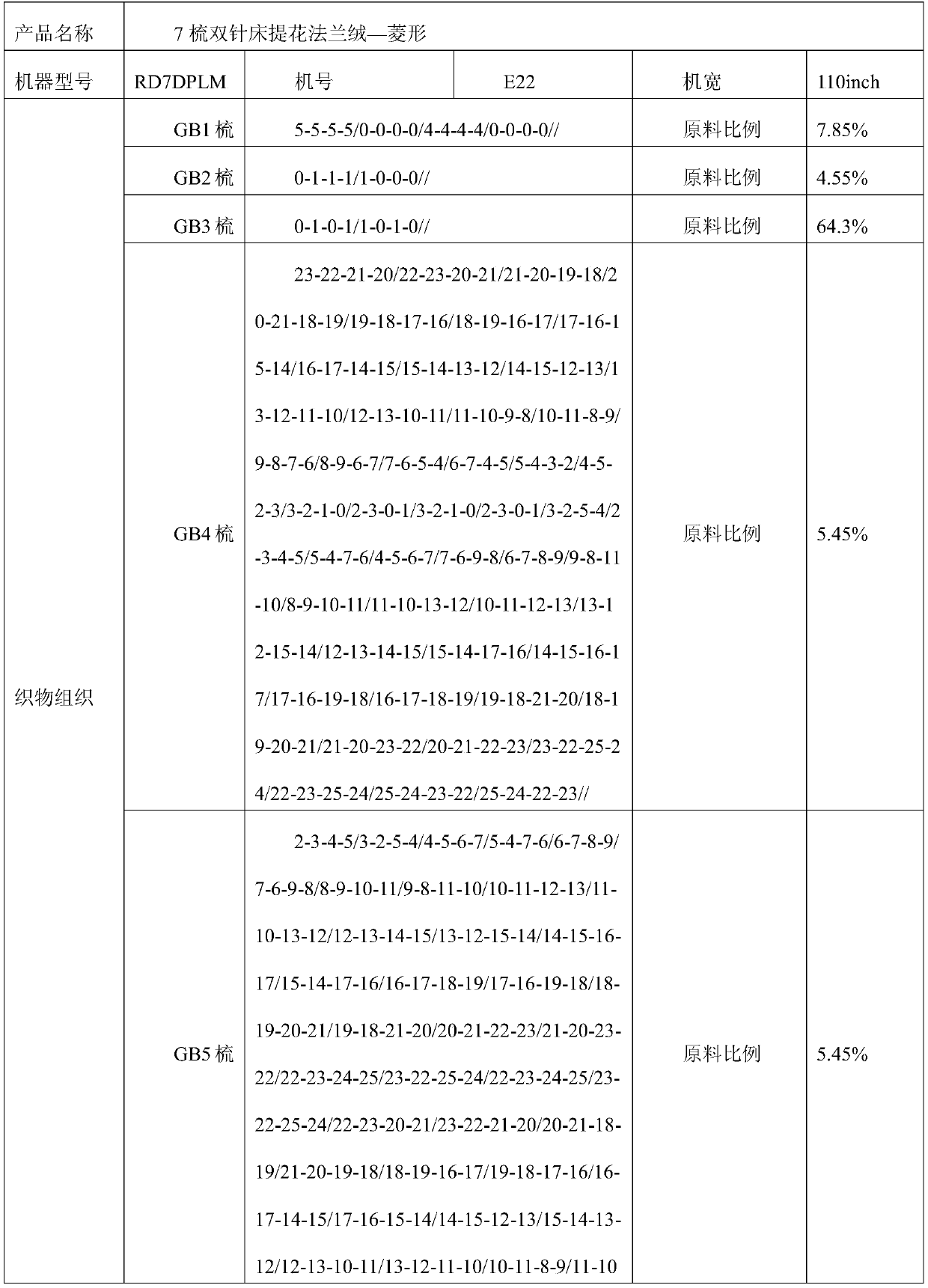

Embodiment 1

[0053] A double-needle bed jacquard flannel fabric with relief effect, which is composed of the following mass percentage components: 75D / 36f semi-gloss polyester FDY is 24.8%, 120D / 192f semi-gloss polyester DTY is 64.3%, 120D / 192f cationic polyester Or yarn-dyed polyester is 10.9%. This fabric uses the high-low pile effect and the pattern to form a diamond pattern with a three-dimensional relief effect.

[0054] The preparation process of the fabric is as follows: the specific process of each process is as follows: including single comb structure selection, preparation process, warping, weaving, setting and so on.

[0055] 1. Preparation process

[0056] Choose 50-100D semi-gloss polyester FDY, 120-200D semi-gloss polyester DTY, 120-200D cationic polyester or yarn-dyed polyester DTY;

[0057] 2. Warping process

[0058] Temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, high and stable temperature and humidity contribute to the stabil...

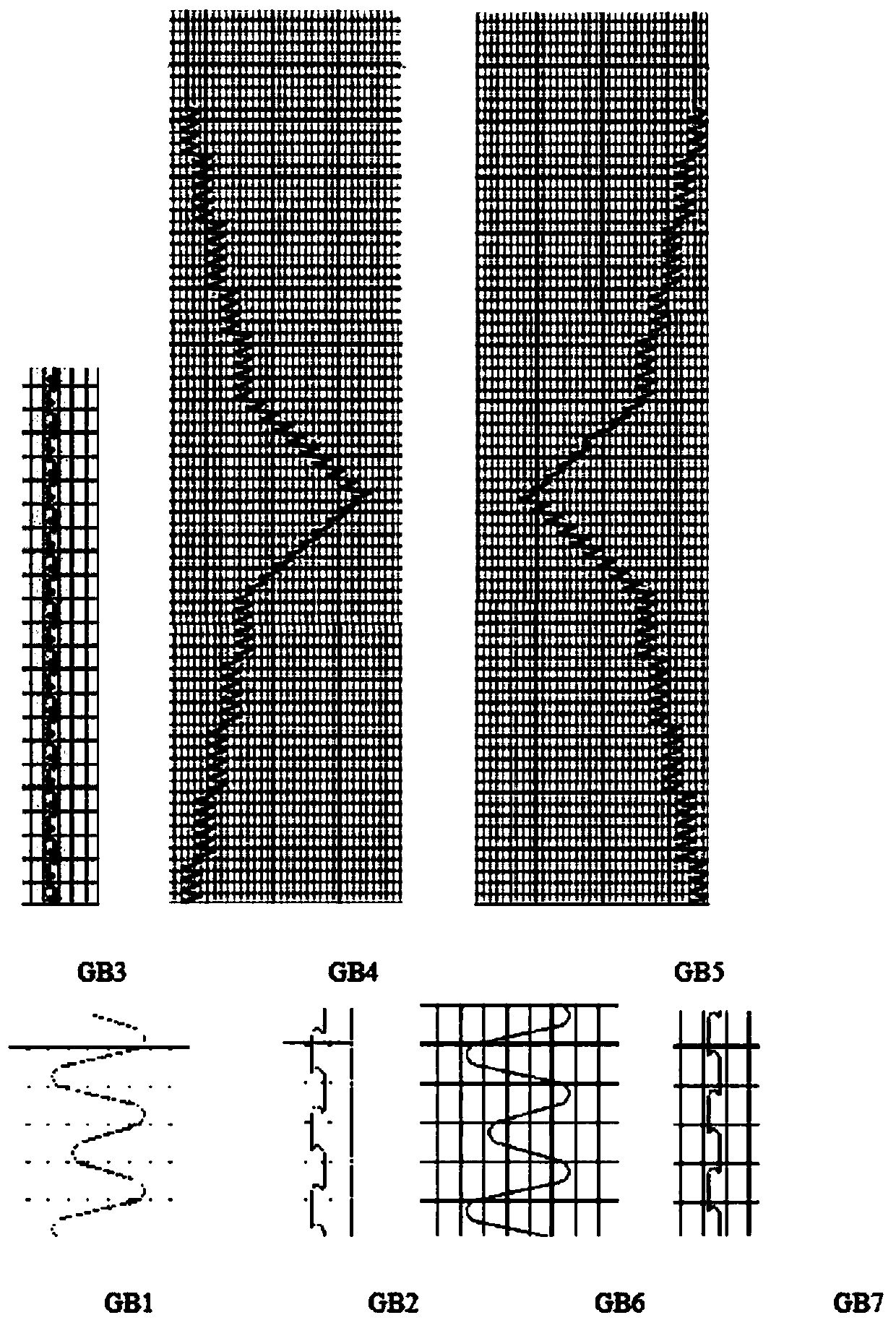

Embodiment 2

[0090] A double-needle bed jacquard flannel fabric with relief effect, which is composed of the following mass percentage components: 75D / 36f semi-gloss polyester FDY is 27.2%, 120D / 192f semi-gloss polyester DTY is 65.8%, 120D / 192f cationic polyester Or yarn-dyed polyester is 7.0%. This fabric utilizes the high-low pile effect and pattern matching to form a star-shaped pattern with a three-dimensional relief effect.

[0091] The preparation process of the fabric is as follows: the specific process of each process is as follows: including single comb structure selection, preparation process, warping, weaving, setting and so on.

[0092] 1. Preparation process

[0093] Choose 50-100D semi-gloss polyester FDY, 120-200D semi-gloss polyester DTY, 120-200D cationic polyester or yarn-dyed polyester DTY;

[0094] 2. Warping process

[0095] Temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, high and stable temperature and humidity are conduciv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com