Centring clamping device

A clamping device and clamping jaw technology, used in toolholder accessories, chucks, turning equipment, etc., can solve the problems of high cost, easy damage, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

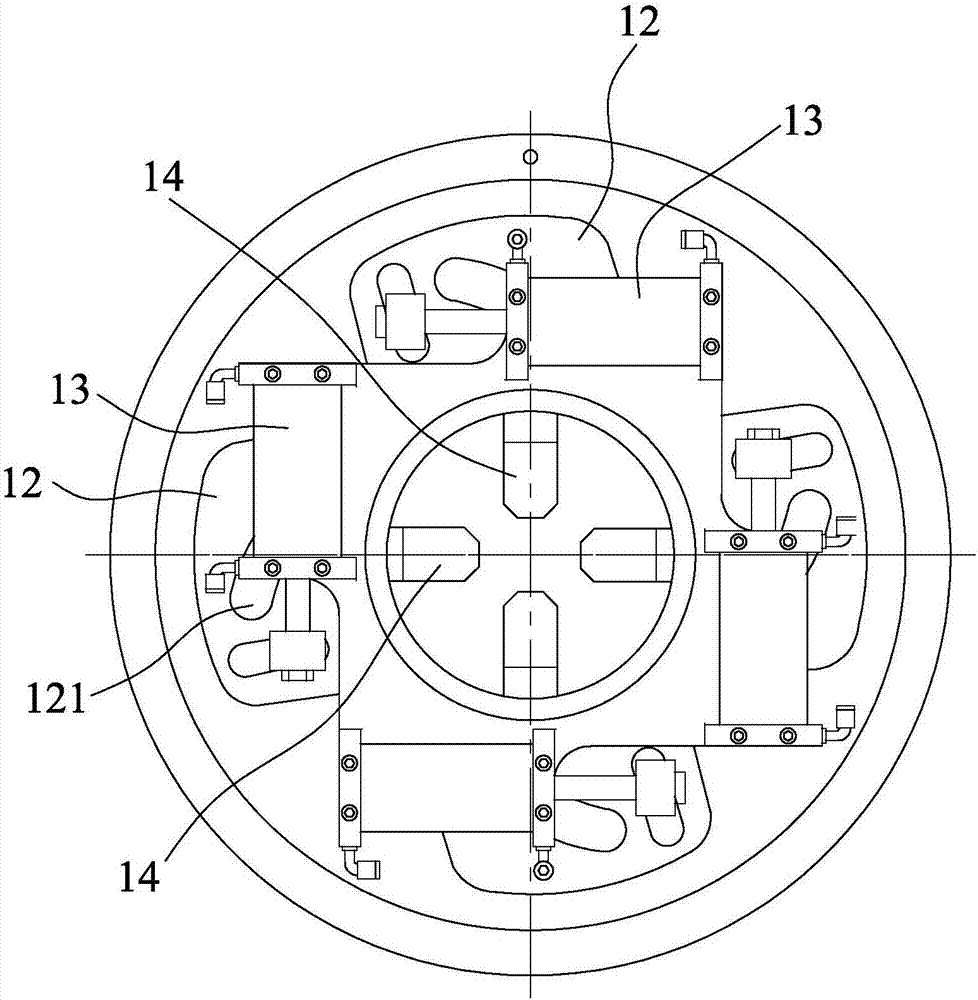

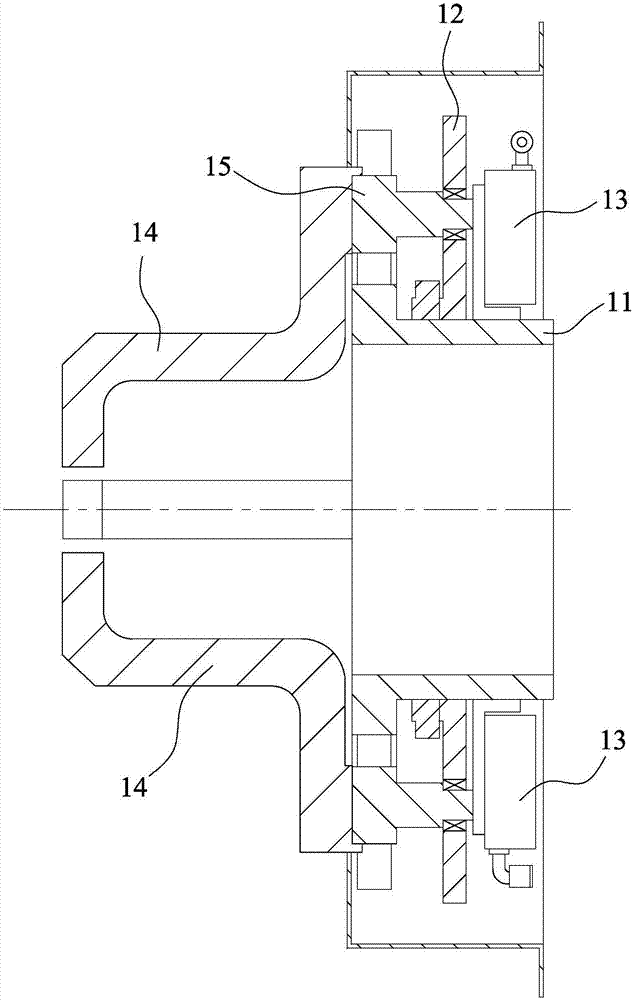

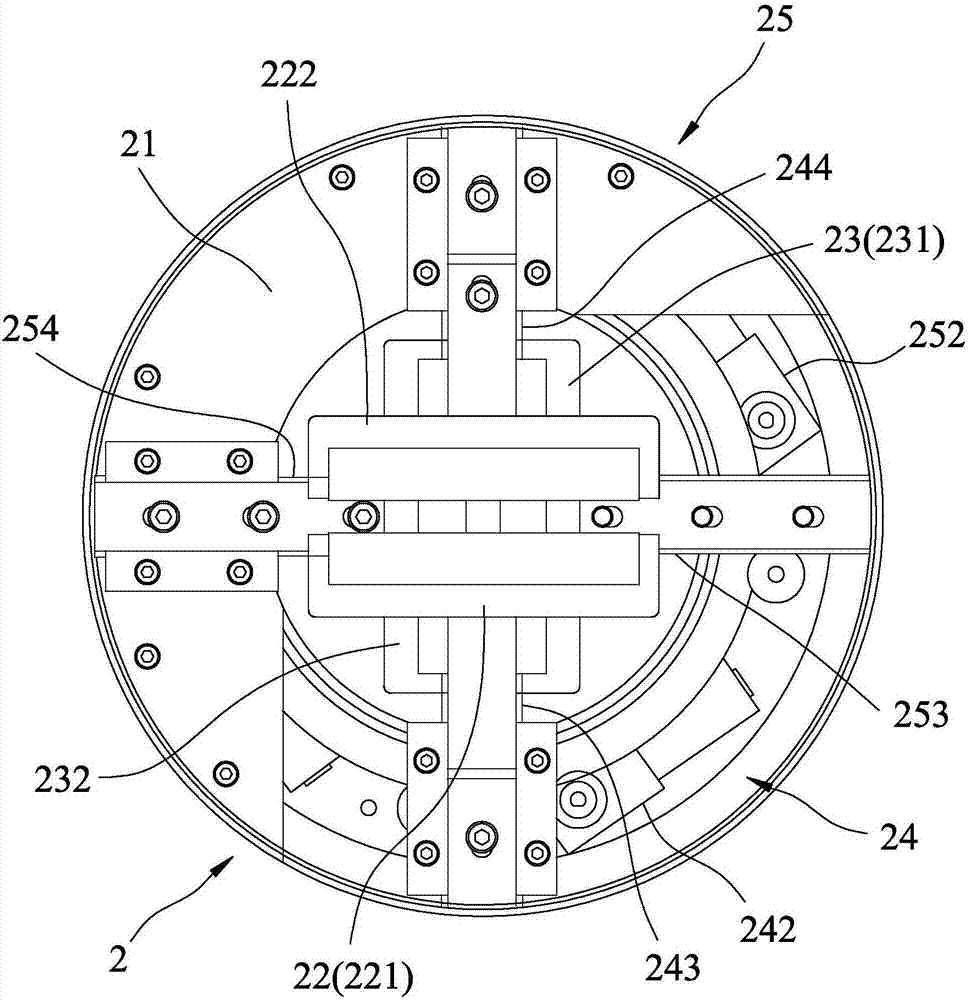

[0029] like Figures 5 to 7 As shown, one embodiment of the centering and clamping device of the present invention includes a base 4 , a clamping module 5 , and a driving module 6 .

[0030] The base 4 includes a seat body 41, and the seat body 41 is defined to have a central axis X, a first axis L1 passing orthogonally through the central axis X, and a second axis L2 passing orthogonally through the central axis X, In this embodiment, the first axis L1 and the second axis L2 are perpendicular to each other.

[0031] The clamping module 5 includes two first clamping jaw units 51 disposed opposite to the base body 41 , and two second clamping jaw units 52 disposed opposite to the base body 41 .

[0032]Each first jaw unit 51 has a first slide rail 511 disposed on the base body 41, a first slide block 512 movably disposed on the first slide rail 511, a first slide block 512 disposed on the first slide block 512 of the first jaw 513 , and a first rack 514 disposed on the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com