Injection molding machine

A technology for injection molding machines and molding materials, which is applied in the field of injection molding machines, can solve the problems of large fluctuations in the quality of molded products, and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In each of the drawings, the same or corresponding components are given the same or corresponding symbols and descriptions thereof are omitted.

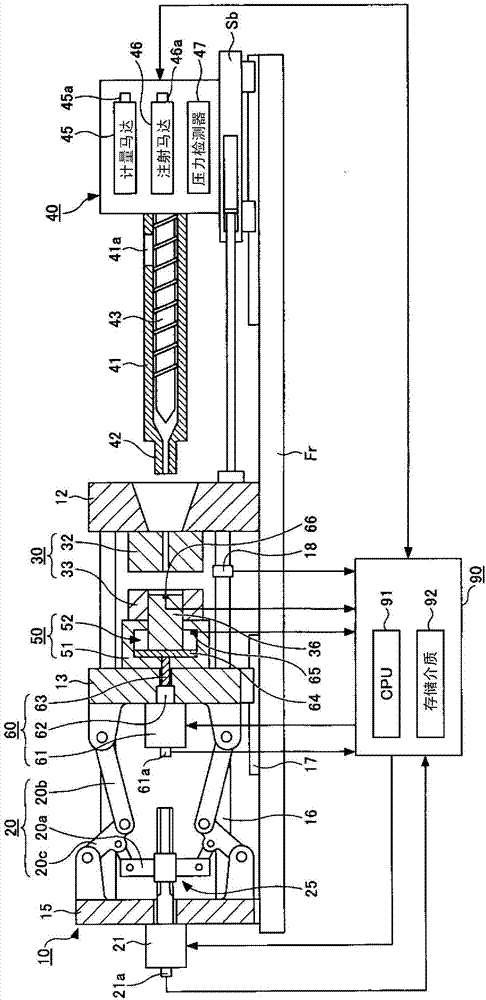

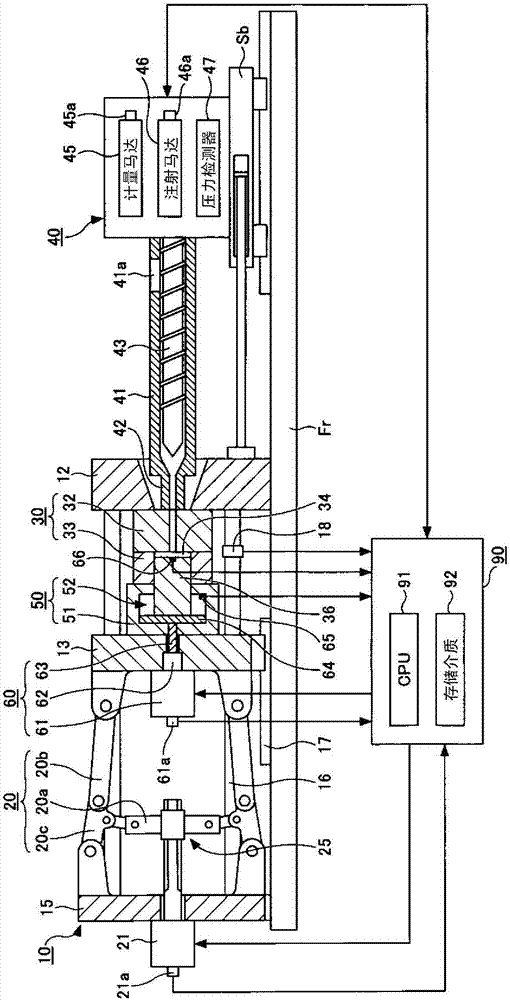

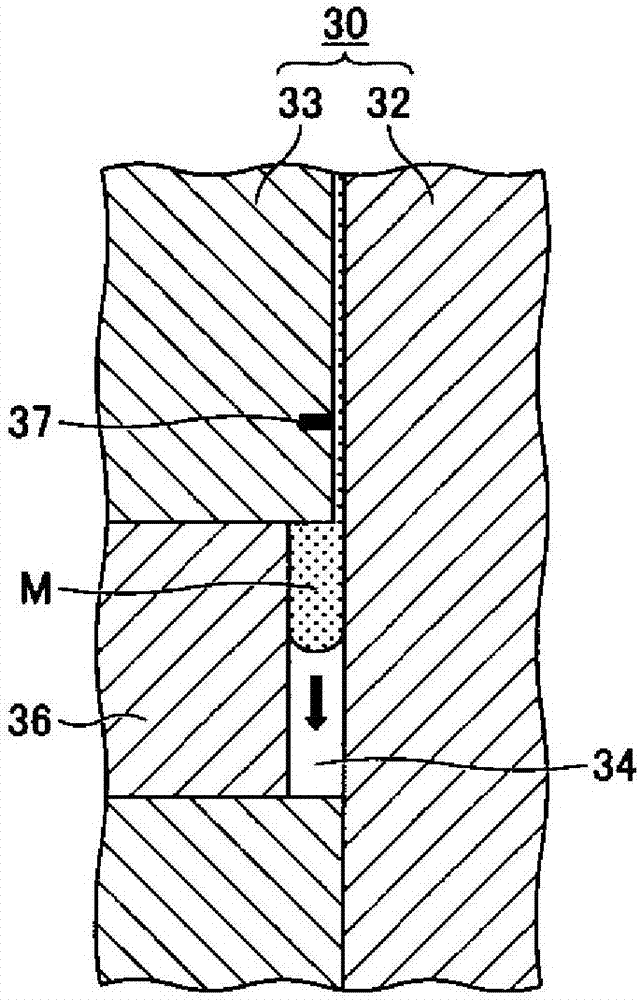

[0019] figure 1 It is a figure which shows the state at the end of mold opening of the injection molding machine of one embodiment. figure 2 It is a figure which shows the state at the time of mold clamping of the injection molding machine of one embodiment. figure 1 and figure 2 In , the flow path of the molding material in the mold device 30 is simplified for convenience of description.

[0020] For example, if figure 1 and figure 2 As shown, the injection molding machine has a frame Fr, a mold clamping device 10 , an injection device 40 , an intermediate device 50 , an ejector device 60 and a control device 90 . In addition, the intermediate unit 50 may be included in the mold unit 30, or may not be included in the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap