Plastic welding machine

A hot-melting machine and plastic technology, applied in the field of plastic hot-melting machines, can solve the problems of increasing the cost of product processing equipment, the fixture base cannot be reused, etc., and achieve the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

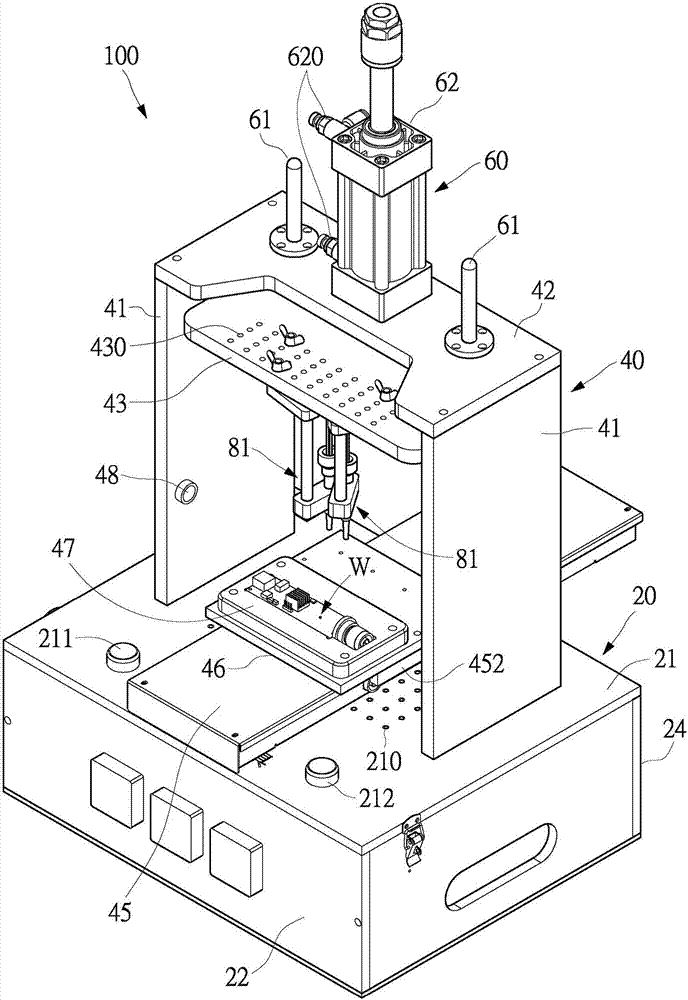

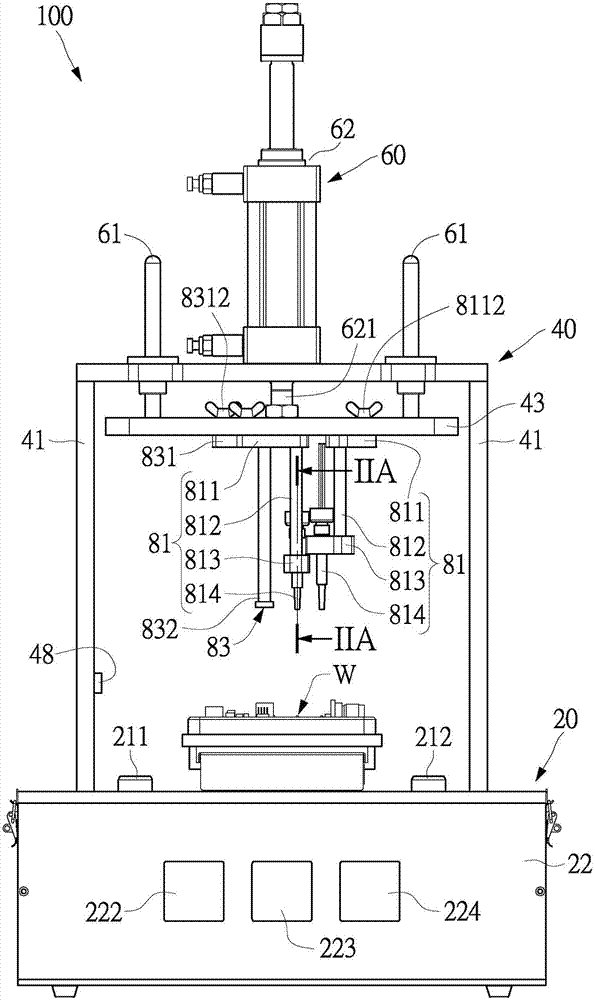

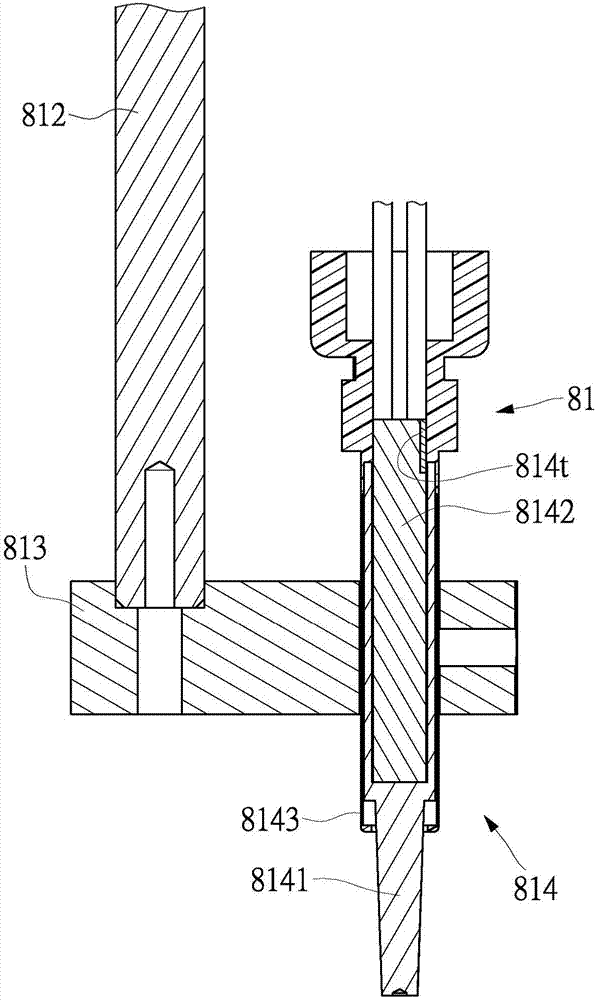

[0078] Please refer to figure 1 and figure 2 , is a perspective view and a front view of the plastic hot-melt machine of the present invention. The present invention provides a plastic hot-melt machine 100, which includes a case 20, a carrying frame 40 disposed on the case 20, a lifting mechanism 60 disposed on the carrying frame 40, an adjustable carrier plate 43 disposed on Inside the carrying frame 40 and a plurality of heating components 81 .

[0079] The case 20 is a cube in this embodiment, and is used for accommodating related control elements and connecting with the outside world. The chassis 20 has at least a top panel 21 , a front panel 22 , and a rear panel 24 . In addition, the chassis 20 further includes a pair of safety buttons 211 , 212 disposed on the top board 21 . The operator needs to press the pair of safety buttons 211 and 212 with both hands at the same time to activate the lifting mechanism 60 to lower the heating assembly 81 to ensure safety.

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap