Novel anti-seismic support special for shield tunnel pre-buried channel

A technology for pre-embedded channels and shield tunnels, which is applied in mining installations, mining equipment, earth-moving drilling, etc., can solve problems such as difficulty in meeting the requirements of seismic specifications, difficulty in meeting lateral seismic requirements, and inability to guarantee lateral stability, etc. Achieve the effect of meeting seismic requirements, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

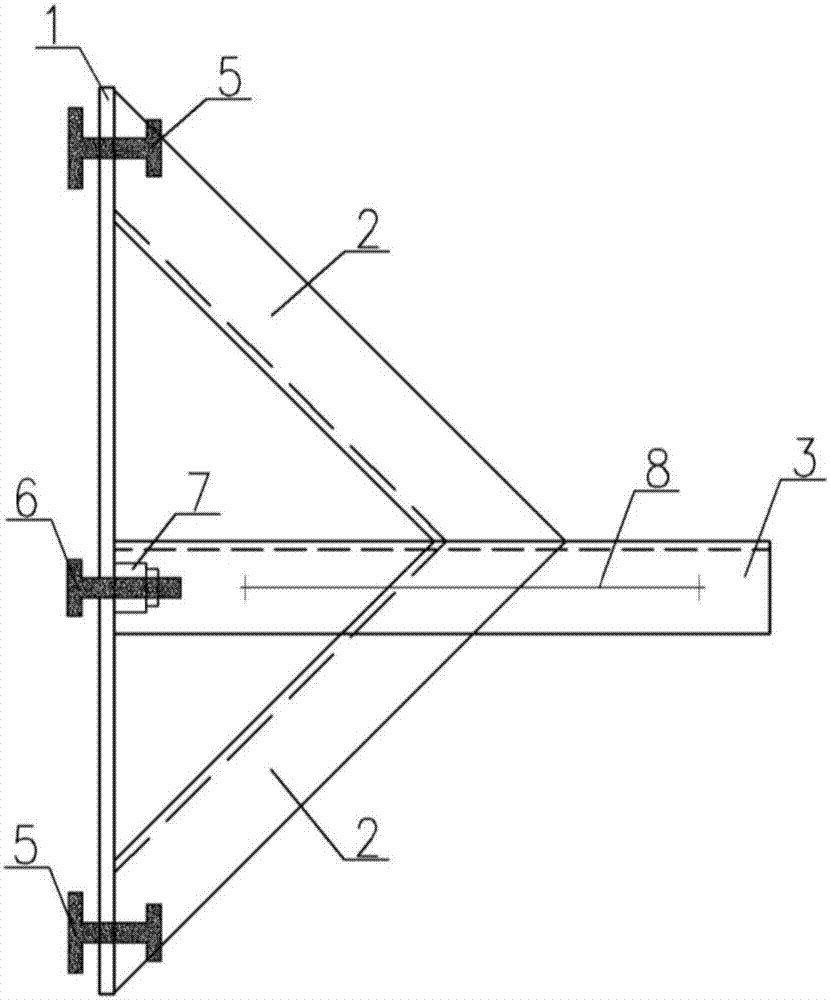

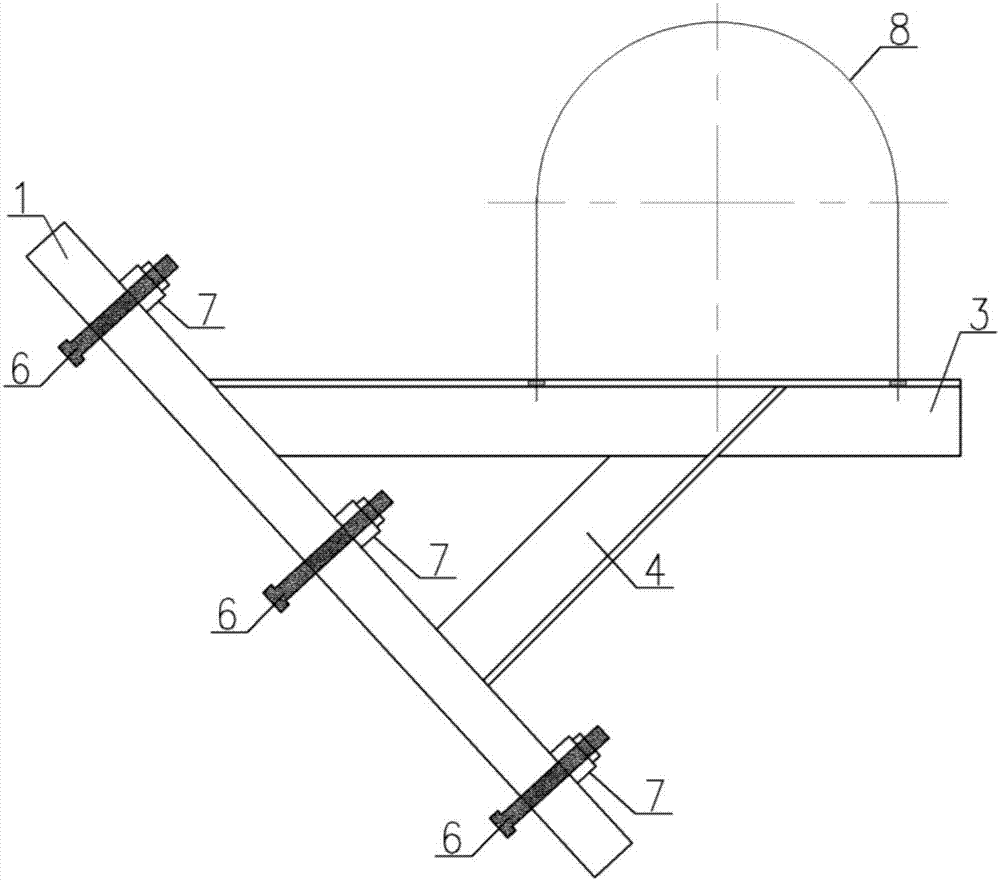

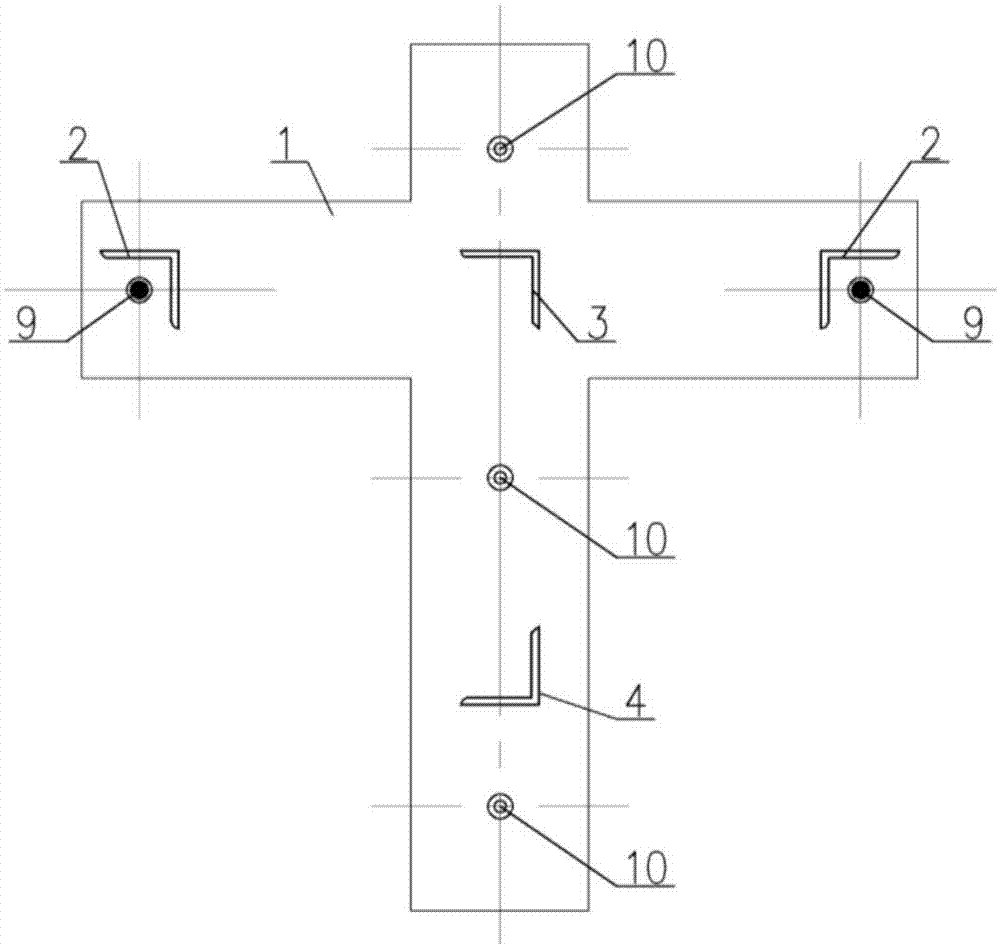

[0024] see as figure 1 —— Figure 6 As shown, this specific embodiment adopts the following technical scheme: it includes base steel plate 1, transverse brace angle steel 2, support angle steel 3, longitudinal brace angle steel 4, jacking bolt 5, chute T-bolt 6, nut 7 and Tube clamp 8; the base steel plate 1 is welded with transverse brace angle steel 2 and longitudinal brace angle steel 4, and the middle part of the base steel plate 1 is welded with support angle steel 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com