Method for evaluating the sound insulation performance of vehicle body side cavity block

A technology of body side circumference and evaluation method, which is applied in the testing of vehicles, testing of machines/structural components, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. To study the sound insulation performance of a single barrier block and other issues to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The invention provides a method for evaluating the sound insulation performance of a body side wall cavity barrier block, which comprises the following steps:

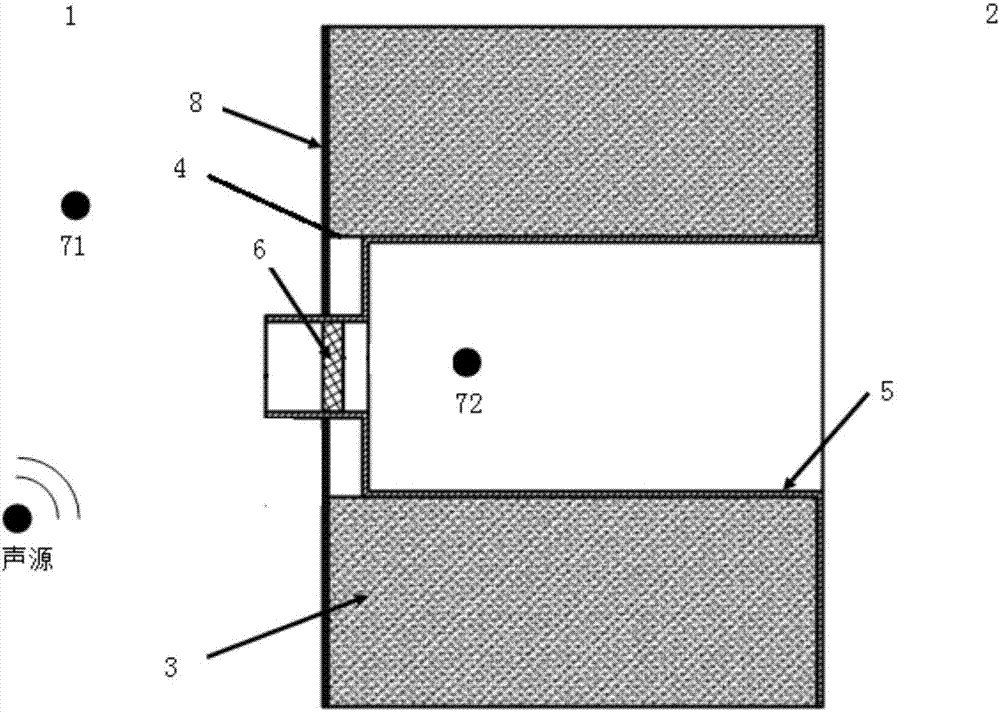

[0030] (1) Build the reverberation chamber 1 and the full anechoic chamber 2, which are separated by a sound-absorbing cotton wall 3 with a thickness of 400mm in the middle, and connected by a connecting channel 4, as figure 1 shown;

[0031] (2) Referring to the SAE standard J2846 for testing the acoustic performance of barrier materials, the barrier block 6 to be tested is placed on the side of the connection channel close to the reverberation chamber 1, and the sound-absorbing baffle 8 is placed around the barrier block parts;

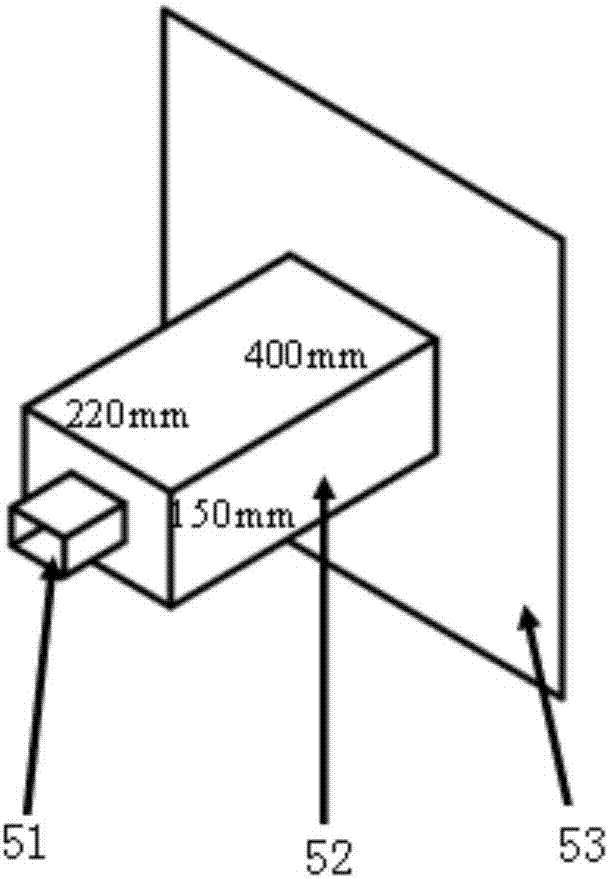

[0032] (3) A cavity channel with a thickness of 22mm is placed on the side of the barrier block 6 to be tested close to the full anechoic chamber 2, such as figure 2 shown, and cover the outer wall of the test piece and the gap between the connecting channel;

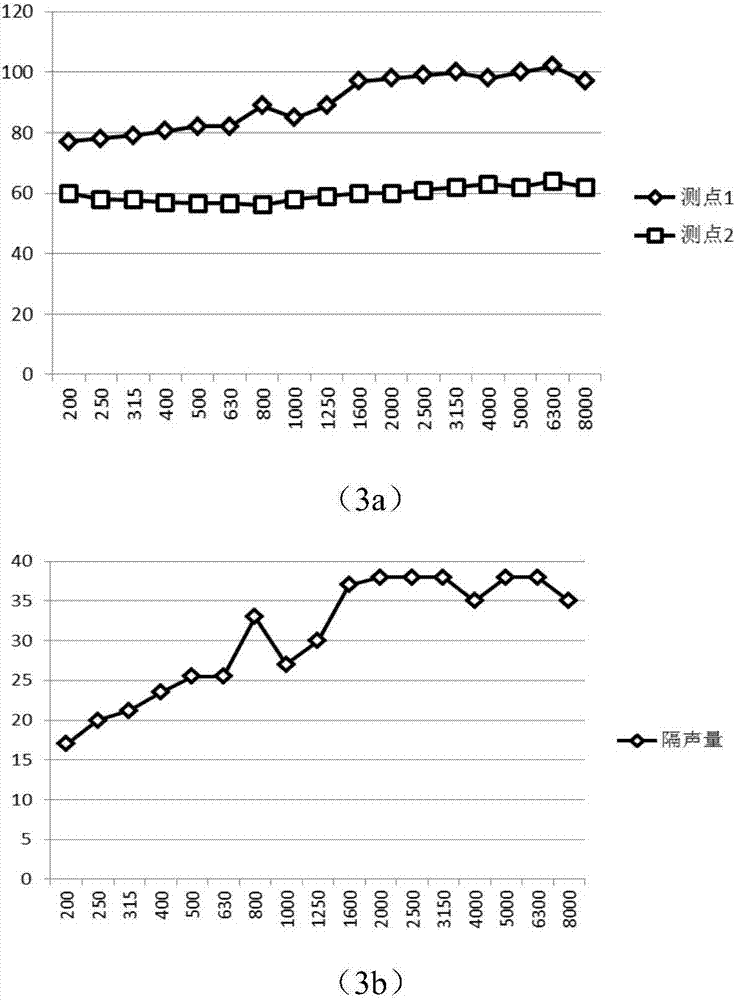

[0033] (4) Arbitrari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com