Aerogel waterborne two-component transparent soundproof coating, and preparation method and application method thereof

A sound-insulating coating and glue-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of discounted sound insulation effect of buildings, poor sound insulation effect of glass windows, and relatively high cost, and achieve urban noise pollution and compatibility Good performance, improve the effect of sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

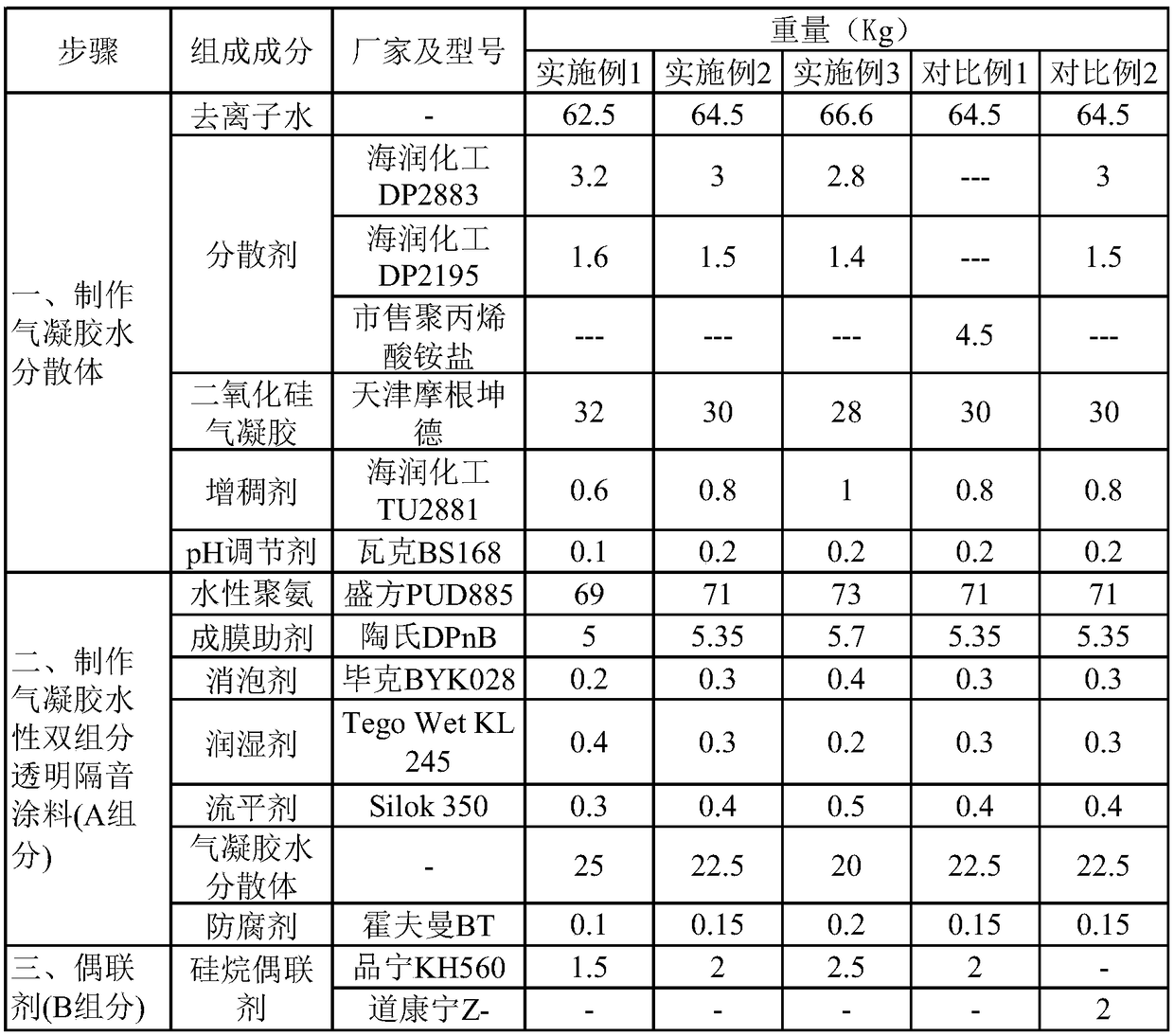

Embodiment 1

[0043] Step 1, preparing a silica airgel aqueous dispersion;

[0044] Add 62.5 kg of deionized water into the pre-dispersion tank, start stirring, then add 3.2 kg of phenolic derivative non-ionic hyperdispersant of Hairun Chemical Co., Ltd. model DP2881 under stirring, stir and mix for 10 minutes after adding, and then Add 32kg of silica airgel particles from Tianjin Morgan Kunde High-tech Development Co., Ltd. at a speed of ~500 rpm and pre-disperse for 10-20 minutes, and then add the phosphate anions of Hairun Chemical Co., Ltd. DP2195 in turn under stirring 1.6kg of dispersant, 0.6kg of TU2881 polyurethane thickener from Hairun Chemical, 0.1kg of BS168 organosilicon pH regulator from Wacker, after adding, stir and increase the stirring speed to 1400-1600 rpm Disperse at high speed for 30 minutes, and then use a pin-type sand mill to grind for 1.5-2.5 hours before being used in step 2.

[0045] Step 2, prepare the A component of the airgel water-based two-component transpar...

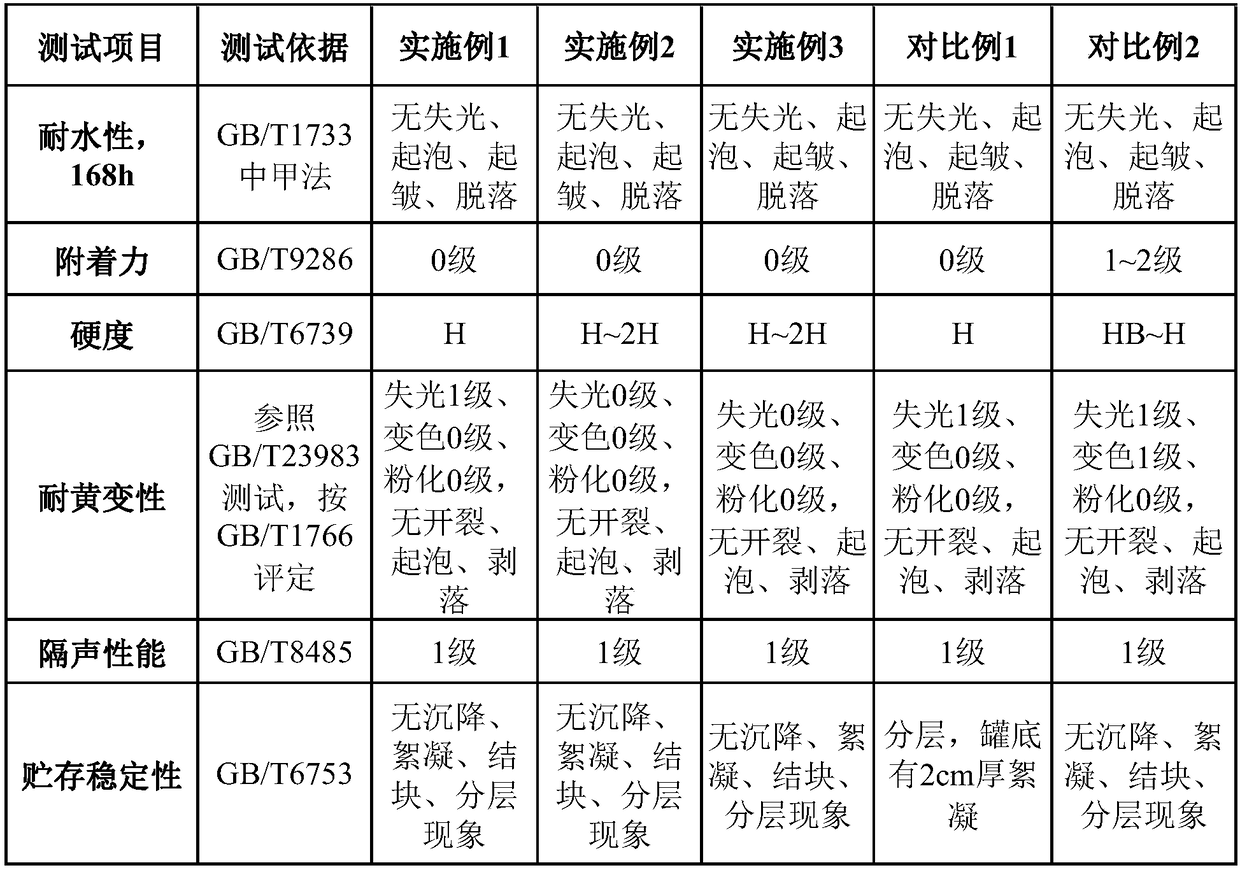

Embodiment 2

[0050] Take each component according to the weight shown in Example 2 in Table 1, and repeat the method described in Example 1, except that 2 kg of component B is used in step 4, diluted with 2 kg of water, and added to component A. The performance testing results are shown in the corresponding data of Example 2 in Table 2.

Embodiment 3

[0052]Take each component according to the weight shown in Example 3 in Table 1, and repeat the method described in Example 1, except that 2 kg of component B is used in step 4, diluted with 2 kg of water, and added to component A. The performance testing results are shown in the corresponding data of Example 3 in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com