Cutting device used for leather manufacturing

A cutting device and leather technology, applied in leather punching/punching/cutting, small raw hide/large raw hide/leather/fur processing, application, etc., can solve the problems of uneven cutting section and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

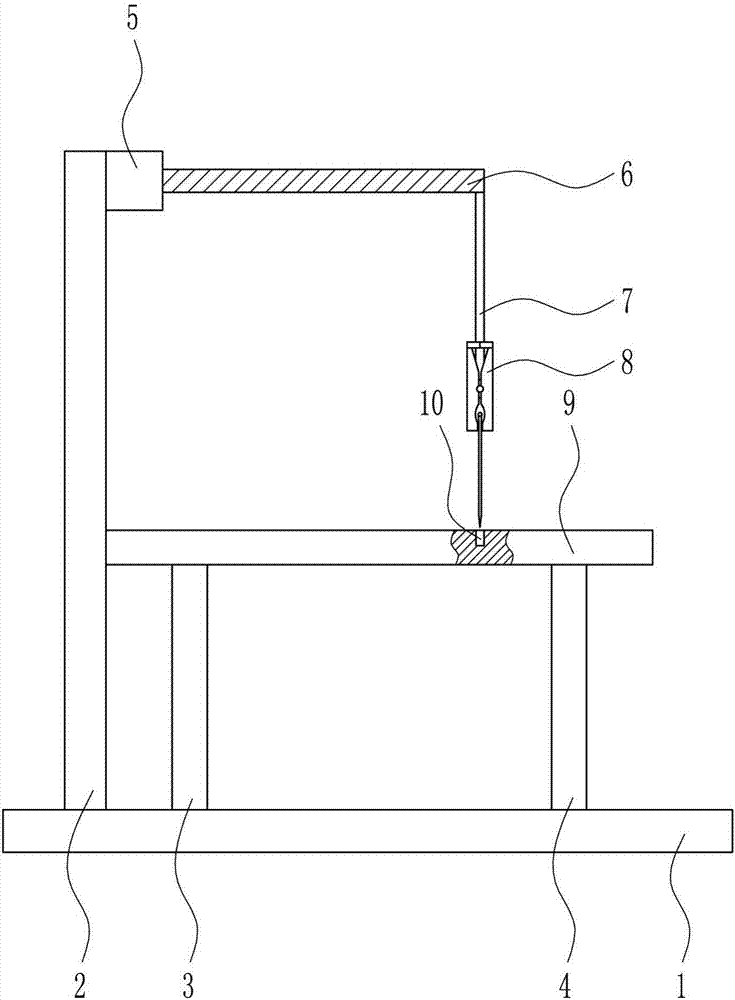

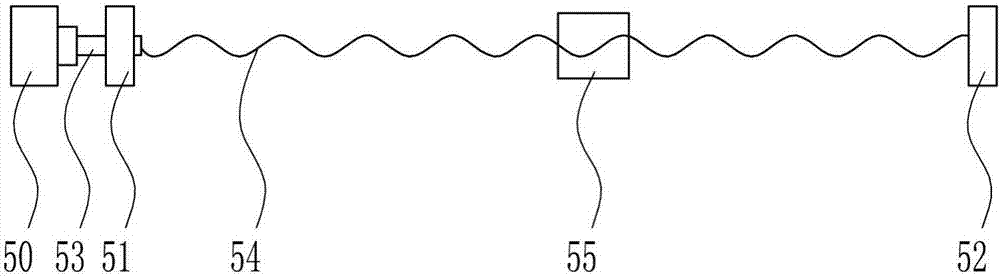

[0037] A cutting device for leather manufacture, such as Figure 1-7 As shown, it includes a base plate 1, a first support 2, a left support 3, a right support 4, a moving device 5, a second support 6, a pole 7, a cutting device 8 and a table 9, and the top of the base plate 1 is in order from left to right There is a first bracket 2, a left bracket 3 and a right bracket 4, a mobile device 5 is provided on the upper right side of the first bracket 2, a second bracket 6 is provided on the right side of the mobile device 5, and a pole is provided at the right end of the bottom of the second bracket 6 7. A cutting device 8 is provided at the lower end of the pole 7, a table 9 is provided on the top of the left bracket 3 and the right bracket 4, and a groove 10 is opened on the right side of the top of the table 9.

Embodiment 2

[0039] A cutting device for leather manufacture, such as Figure 1-7 As shown, it includes a base plate 1, a first support 2, a left support 3, a right support 4, a moving device 5, a second support 6, a pole 7, a cutting device 8 and a table 9, and the top of the base plate 1 is in order from left to right There is a first bracket 2, a left bracket 3 and a right bracket 4, a mobile device 5 is provided on the upper right side of the first bracket 2, a second bracket 6 is provided on the right side of the mobile device 5, and a pole is provided at the right end of the bottom of the second bracket 6 7. A cutting device 8 is provided at the lower end of the pole 7, a table 9 is provided on the top of the left bracket 3 and the right bracket 4, and a groove 10 is opened on the right side of the top of the table 9.

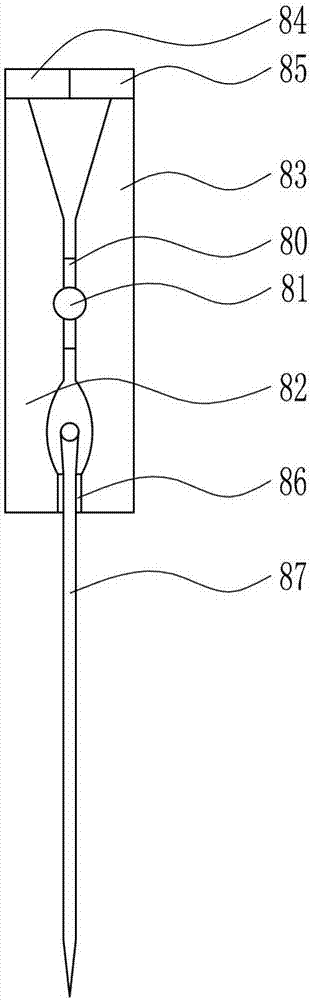

[0040] The cutting device 8 includes a first bearing seat 80, a second rotating shaft 81, a left clamping plate 82, a right clamping plate 83, a first magnet 84, an i...

Embodiment 3

[0042] A cutting device for leather manufacture, such as Figure 1-7 As shown, it includes a base plate 1, a first support 2, a left support 3, a right support 4, a moving device 5, a second support 6, a pole 7, a cutting device 8 and a table 9, and the top of the base plate 1 is in order from left to right There is a first bracket 2, a left bracket 3 and a right bracket 4, a mobile device 5 is provided on the upper right side of the first bracket 2, a second bracket 6 is provided on the right side of the mobile device 5, and a pole is provided at the right end of the bottom of the second bracket 6 7. A cutting device 8 is provided at the lower end of the pole 7, a table 9 is provided on the top of the left bracket 3 and the right bracket 4, and a groove 10 is opened on the right side of the top of the table 9.

[0043] The cutting device 8 includes a first bearing seat 80, a second rotating shaft 81, a left clamping plate 82, a right clamping plate 83, a first magnet 84, an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com