Mold for production of continuous fiber reinforced thermoplastic plastic

A technology of reinforced thermoplastics and continuous fibers, which is applied in the field of molds for the production of continuous fiber-reinforced thermoplastics. It can solve the problems of yarn bundles accumulating together, and achieve the effect of increasing the dispersion width and promoting infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

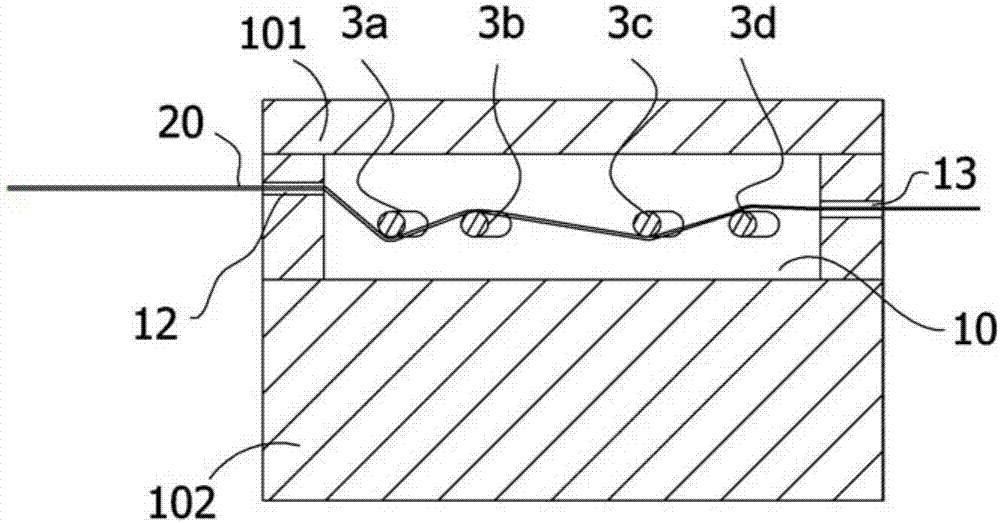

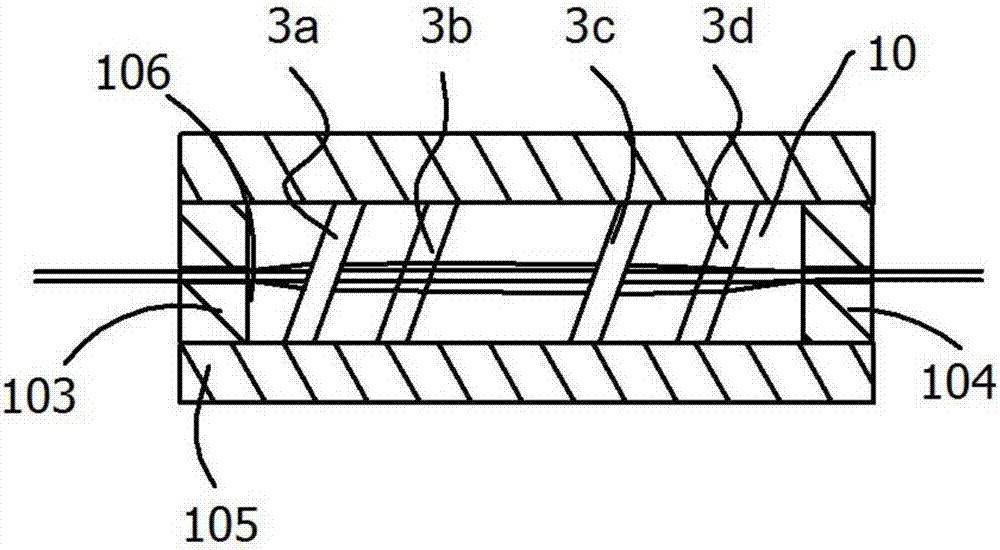

[0031] Embodiment one, see appendix Figure 1~3 , a mold for producing continuous fiber reinforced thermoplastics, comprising an upper mold base 101 and a lower mold base 102, left, right, front and rear mold walls 103, 104, 105 and 106, a mold cavity 10 is formed between the upper mold base, the lower mold base, the left mold wall, the right mold wall, the front mold wall and the rear mold wall, the left mold wall is provided with a feed channel, and the right mold wall is provided with In the discharge channel, the continuous fiber yarn bundle is fed from the left mold wall and discharged from the right mold wall; two groups of fiber dispersions are installed between the front mold wall and the rear mold wall, and each group of fiber dispersions includes two Fiber dispersion blocks, the fiber dispersion blocks are pins, and the two fiber dispersion blocks in each group are parallel to each other, and each group of fiber dispersions is parallel to or not parallel to each othe...

Embodiment 2

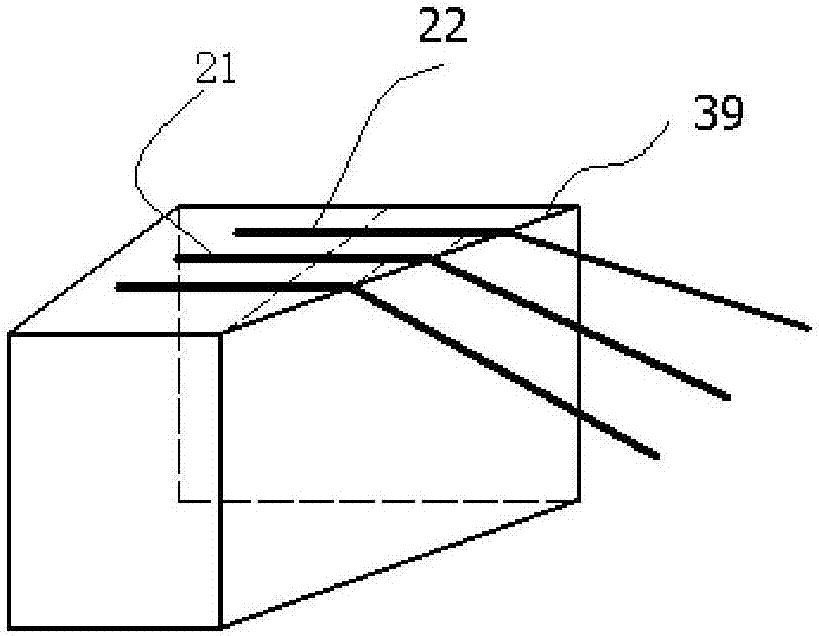

[0034] Embodiment two, see appendix Figure 4 and 5 , including an upper mold base and a lower mold base, left, right, front and rear mold walls are installed between the upper mold base and the lower mold base, the upper mold base, lower mold base, left mold wall, right mold wall, A mold cavity 10 is formed between the front mold wall and the rear mold wall. The left mold wall is provided with a feed channel, and the right mold wall is provided with a discharge channel. The continuous fiber yarn is fed from the left mold wall and exited from the right mold wall. material; the fiber dispersion block is 4 groups of oblique prism structures 3a', 3b', 3c', 3d', and each group of oblique prism structures is provided with a cylindrical surface in contact with the continuous fiber yarn bundle, and the lower side of the upper mold wall is installed There are two sets of oblique prism structures, and two sets of oblique prism structures are also installed on the upper side of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com