Conveying device capable of effectively controlling unwinding tension

A conveying device and tension technology, applied in the field of conveying devices that effectively control unwinding tension, can solve the problems of fiber appearance quality influence, woolen environment pollution, easy generation of voids, etc., so as to improve product quality and production efficiency, and improve yarn spreading. effect, the effect of increasing the spread width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

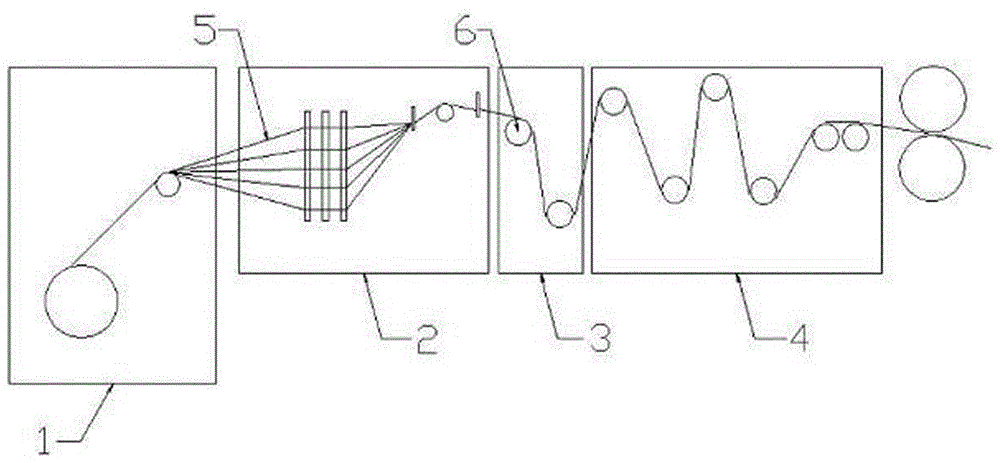

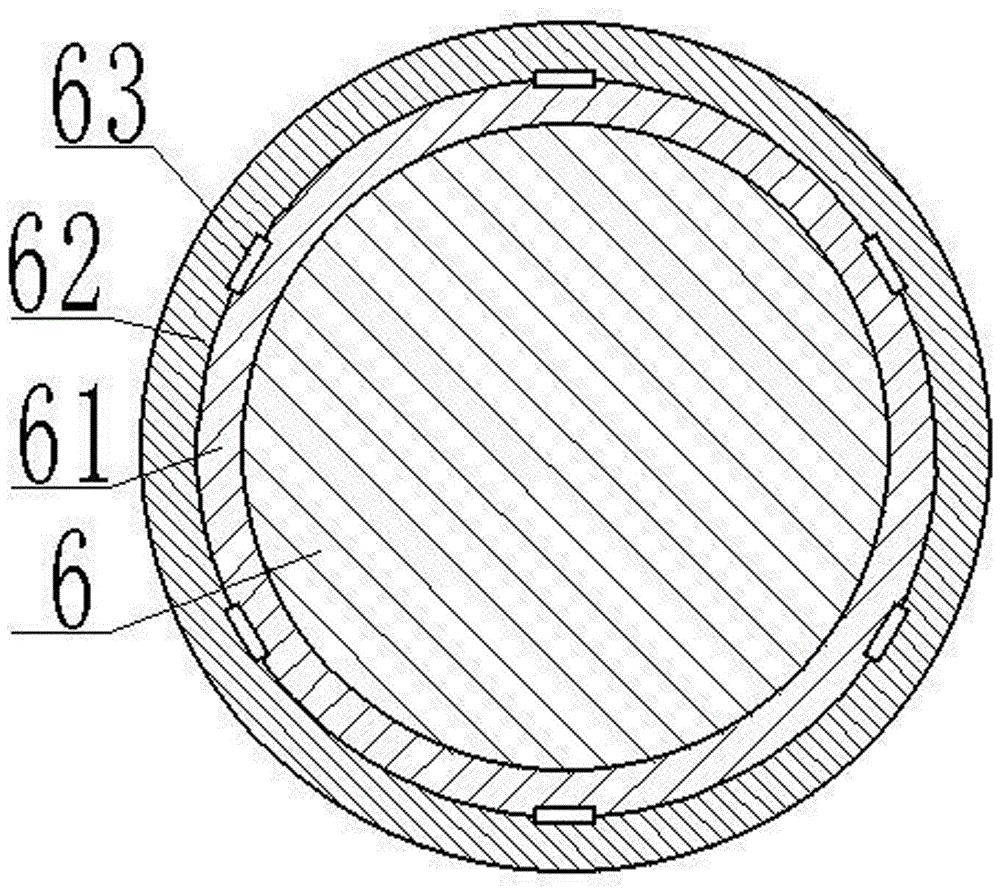

[0028] Such as figure 1 , 2 , 3, a conveying device for effectively controlling the unwinding tension, comprising an unwinding mechanism 1, a threading mechanism 2, a fixed spreading roller group 3 and a spreading mechanism 4 arranged in sequence, and is characterized in that: the fixed The ends of the spreading rollers 6 of the spreading roller group 3 are connected and installed through elastic components. The surface of the spreading rollers 6 is provided with a silica gel layer 61 and a wear-resistant layer 62 in turn. The wear-resistant layer 62 and the silica gel layer 61 A resistance strain gauge pressure sensor 63 is arranged between them, and the wear-resistant layer 62 is made of nitrile rubber. The resistance strain gauge pressure sensor 63 is connected to the wireless communication module, and the wireless communication module is connected to the display screen through a wireless connection.

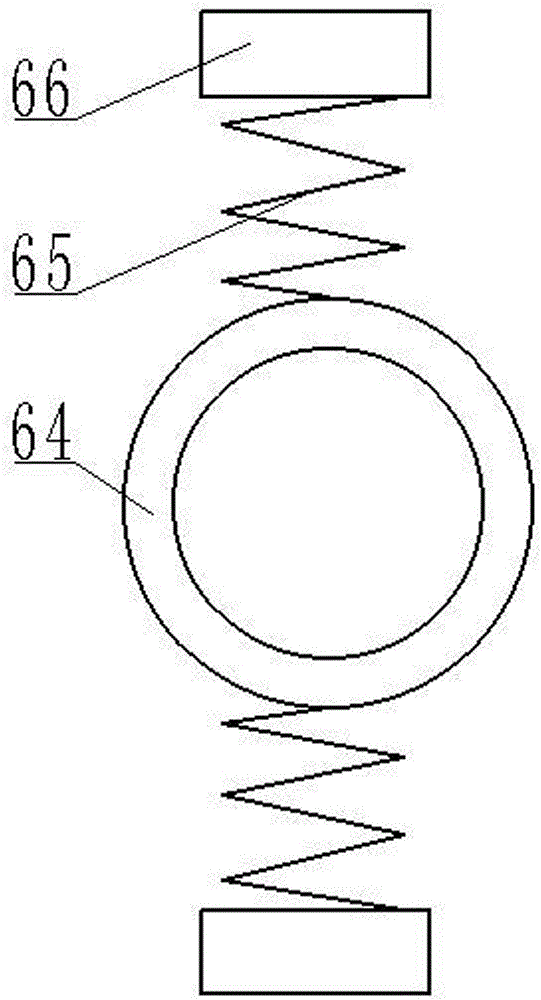

[0029] Described elastic component is tension spring 65 and buffer mat...

Embodiment 2

[0032] Such as figure 1 , 2 , 4, a conveying device that effectively controls the unwinding tension, including an unwinding mechanism 1, a threading mechanism 2, a fixed spreading roller group 3 and a spreading mechanism 4 arranged in sequence, is characterized in that: the fixed The ends of the spreading rollers 6 of the spreading roller group 3 are connected and installed through elastic components. The surface of the spreading rollers 6 is provided with a silica gel layer 61 and a wear-resistant layer 62 in turn. The wear-resistant layer 62 and the silica gel layer 61 A resistance strain gauge pressure sensor 63 is arranged between them, and the wear-resistant layer 62 is made of nitrile rubber. The resistance strain gauge pressure sensor 63 is connected to the wireless communication module, and the wireless communication module is connected to the display screen through a wireless connection.

[0033] Described elastic component is tension spring 65 and buffer material l...

Embodiment 3

[0036] Such as figure 1 , 2 , 5, a conveying device that effectively controls the unwinding tension, including an unwinding mechanism 1, a threading mechanism 2, a fixed spreading roller group 3 and a spreading mechanism 4 arranged in sequence, is characterized in that: the fixed The ends of the spreading rollers 6 of the spreading roller group 3 are connected and installed through elastic components. The surface of the spreading rollers 6 is provided with a silica gel layer 61 and a wear-resistant layer 62 in turn. The wear-resistant layer 62 and the silica gel layer 61 A resistance strain gauge pressure sensor 63 is arranged between them, and the wear-resistant layer 62 is made of nitrile rubber. The resistance strain gauge pressure sensor 63 is connected to the wireless communication module, and the wireless communication module is connected to the display screen through a wireless connection.

[0037] Described elastic component is tension spring 65 and buffer material l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com