Full-automatic tea spreading machine

A greening machine, fully automatic technology, applied in the field of machinery and equipment, can solve the problems of long spreading time, low spreading efficiency, great influence of weather and site, etc., to achieve improved spreading effect, low manufacturing cost, and not easy to damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

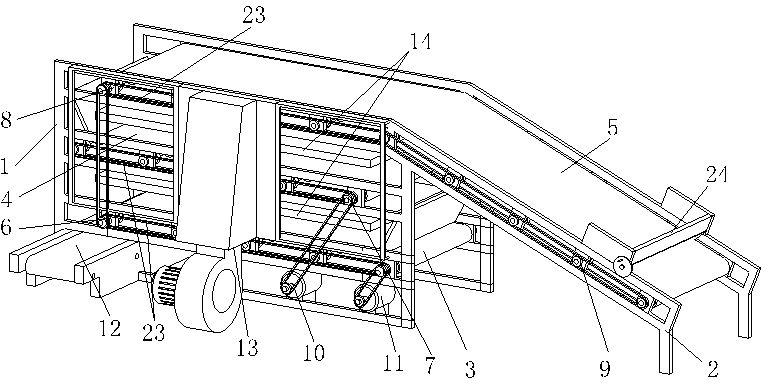

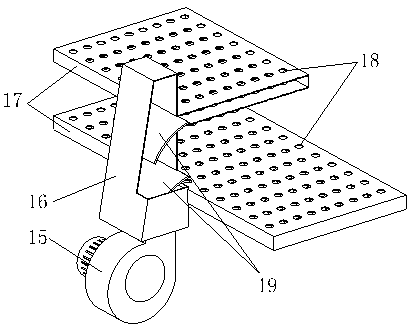

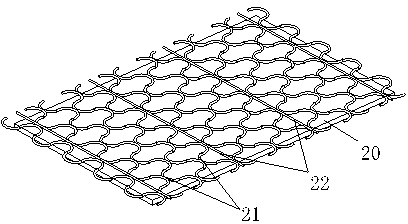

[0018] Embodiments of the present invention: as figure 1 Shown, a kind of full-automatic tea stand green machine, comprises green stand body 1, feed frame body 2, first conveyer belt 3, second conveyer belt 4 and the 3rd conveyer belt 5, feed frame body 2 is inclined to set, feed frame body 2 One end of the stand is fixedly connected to the top of the stand body 1, and the stand body 1 is provided with the first idler group 6, the second idler group 7 and the third idler group 8 sequentially from bottom to top, and the feeding rack body 2 Feeding roller group 9 is installed on it, the first conveyor belt 3 is wound on the first roller group 6, the second conveyor belt 4 is wound on the second roller group 7, the third conveyor belt 5 is wound on the third roller group 8 and On the feeding roller gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com