Cover module capable of opening by rotating

A component and cover technology, which is applied in the field of cover components, can solve the problems of not being able to install sealing sheets and pull rings, and achieve the effects of simple structure, good liquid discharge and sealing, and convenient and hygienic use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

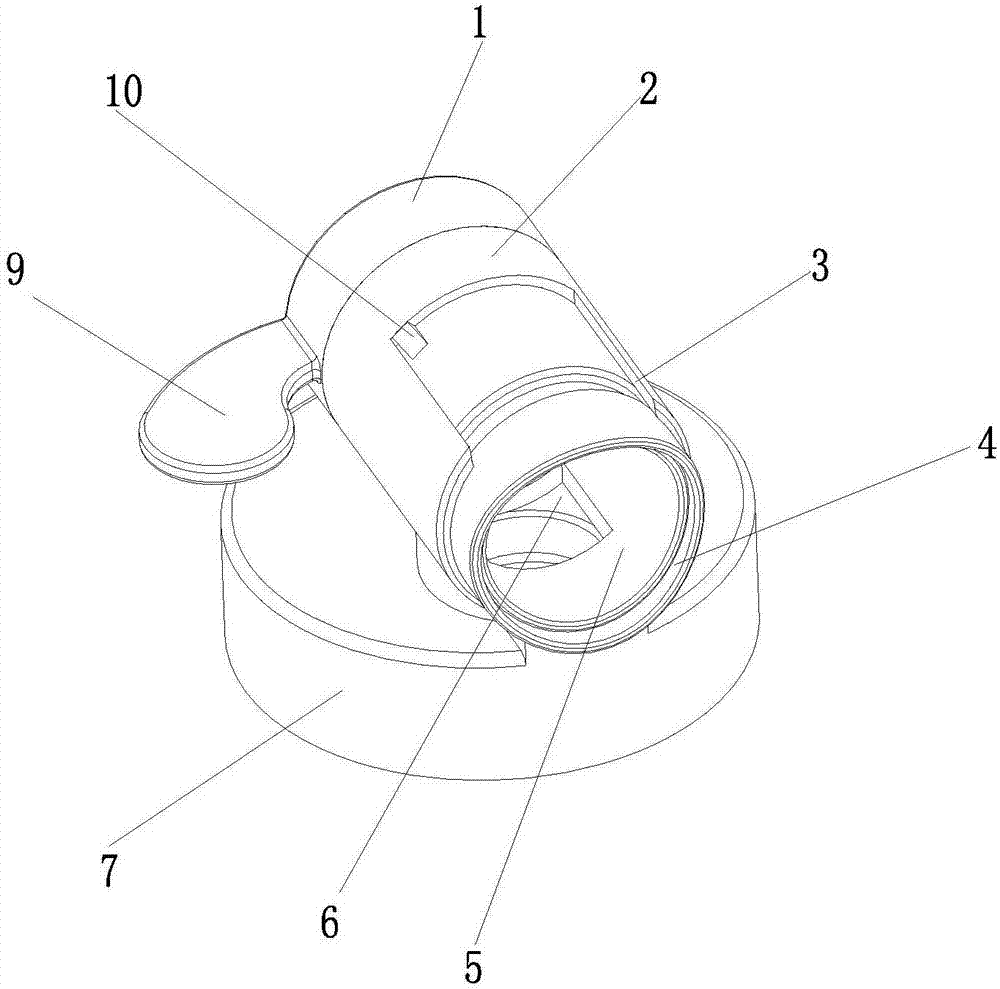

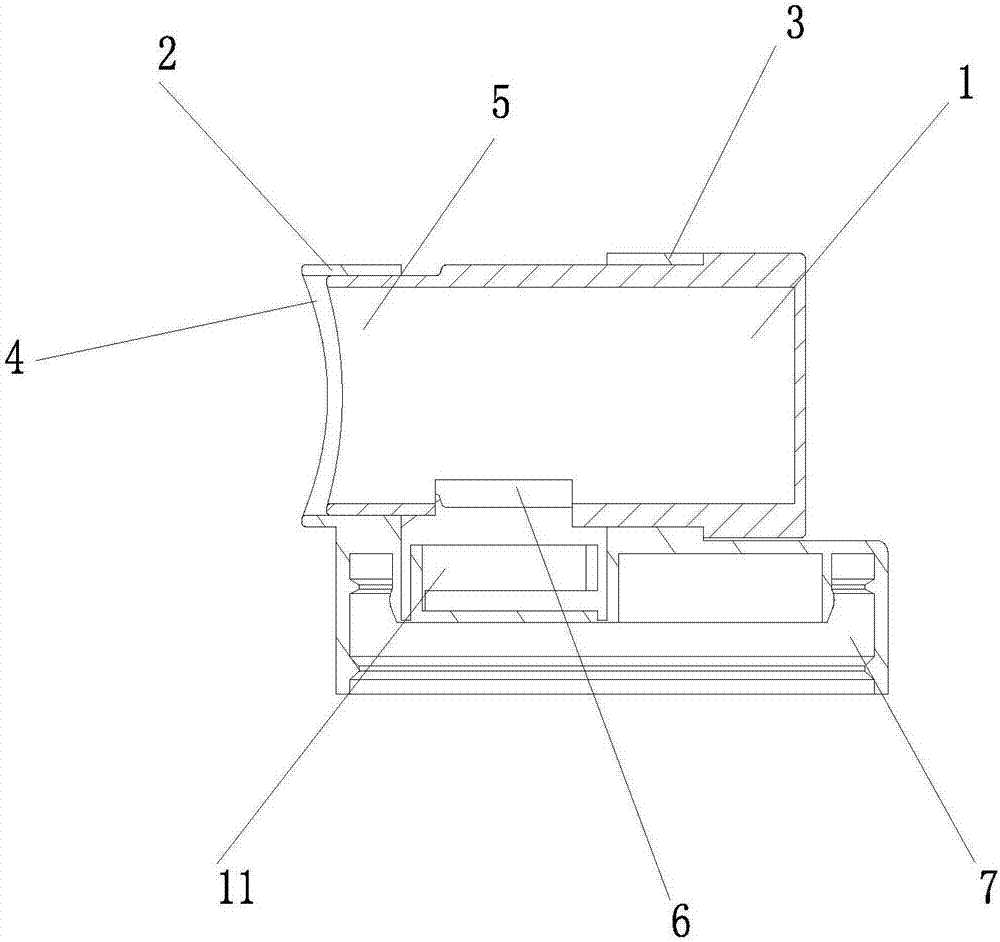

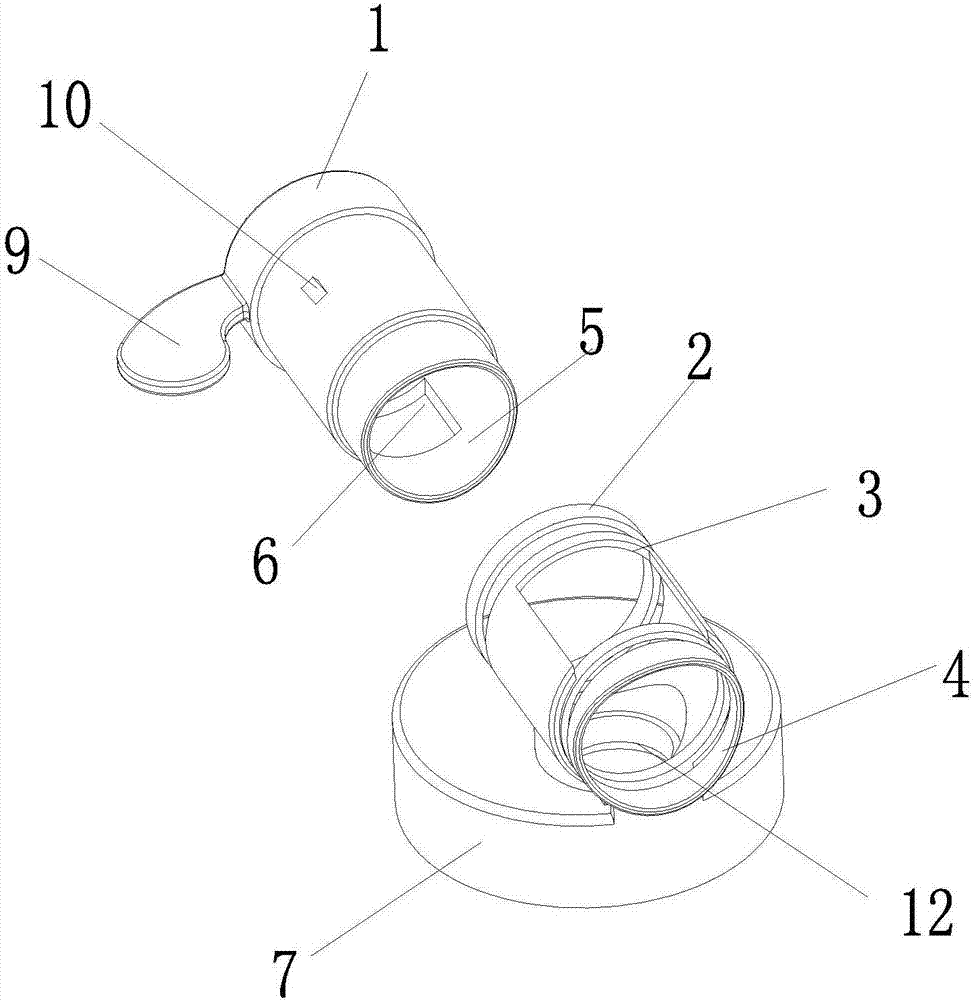

[0014] Embodiment one: refer to Figure 1-Figure 5 Shown:

[0015] A cap assembly that can be turned and opened is provided, including a lower cap seat 7 that is buckled or screwed on the liquid outlet of the container. A transverse tube body 2 is provided on the top surface of the lower cap seat 7, and one end of the transverse tube body 2 is A liquid outlet port, a lower liquid outlet hole 12 is provided between the horizontal pipe body 2 and the top surface of the lower cover seat 7, and a breakable sealing sheet 11 is integrally formed in the lower liquid outlet hole 12, the A pull ring is provided on the upper surface of the sealing sheet 11; a square or polygonal opening 3 corresponding to the lower outlet hole is provided on the tube body of the transverse tube body 2, and a A rotatable rotating tube 1, one end of the rotating tube 1 is closed, the other end of the rotating tube 1 is a liquid outlet port, the tube body at the closed end is provided with a limit step, a...

Embodiment 2

[0017] Embodiment two: refer to Figure 6-Figure 7 Shown:

[0018] The second embodiment is based on the first embodiment, an outer baffle 15 is integrally formed on the inner hole wall of the liquid outlet port of the horizontal pipe body 2, and one or more outer liquid outlets 16 are opened on the outer baffle, and the above-mentioned The structure can have a buffering effect on the liquid flowing out of the end of the pipe body. The working principle is the same as that of the first embodiment.

Embodiment 3

[0019] Embodiment three: refer to Figure 6-Figure 7 Shown:

[0020] In the third embodiment, on the basis of the first embodiment, an inner baffle 17 can be integrally formed at the liquid outlet port of the rotating tube 1, and one or more inner liquid outlets 14 are opened on the inner baffle. Adding the above-mentioned structure can have a buffering effect on the liquid flowing out from the end of the pipe body. The working principle is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com