Swing-type conveyor

A conveyor and swinging technology, applied in the field of swinging conveyors, can solve the problems of low production and conveying capacity, short service life, and backward overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

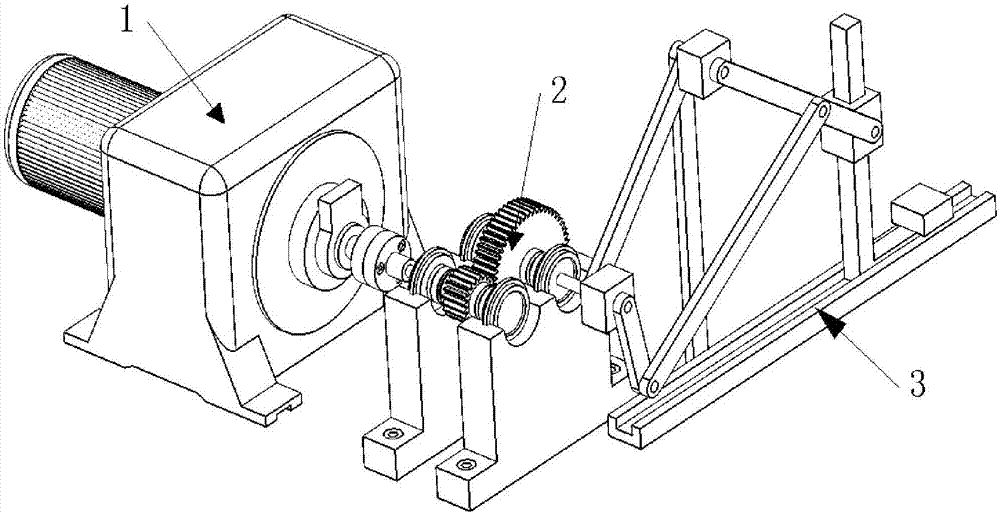

[0014] Such as figure 1 As shown, a swing conveyor includes a motor 1 fixed on the worktable to provide power for the whole mechanism. The motor 1 is connected with a transmission mechanism 2, the transmission mechanism 2 is a pair of gears meshing, the transmission mechanism 2 is connected with the output shaft of the motor 1 through a coupling, and has the function of deceleration. The transmission mechanism 2 is fixed on the machine base.

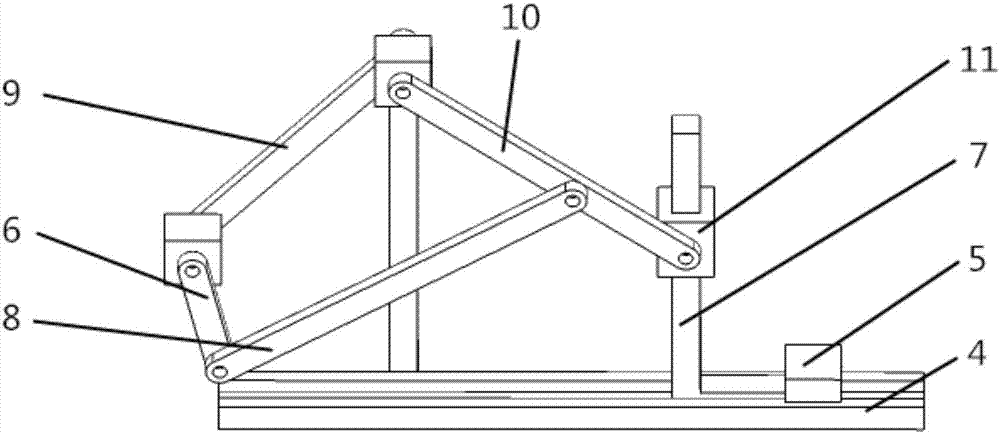

[0015] Such as figure 2 Shown, also comprise six-bar linkage mechanism 3, described six-bar linkage mechanism 3 comprises crank 6, connecting rod 7, guide rod 8, fixed rod 9, rocking bar 10, slide block 11, described crank 6 one ends and Guide rod 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com