Battery core needle rotation and revolution device

A technology for winding needles and needles of battery cells, which is applied to circuits, electrical components, secondary batteries, etc., can solve the problems of high requirements for revolution drive components, complex turret devices, and large moment of inertia, and achieves compact structure, high rotational speed, etc. Effects of reduced inertia and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

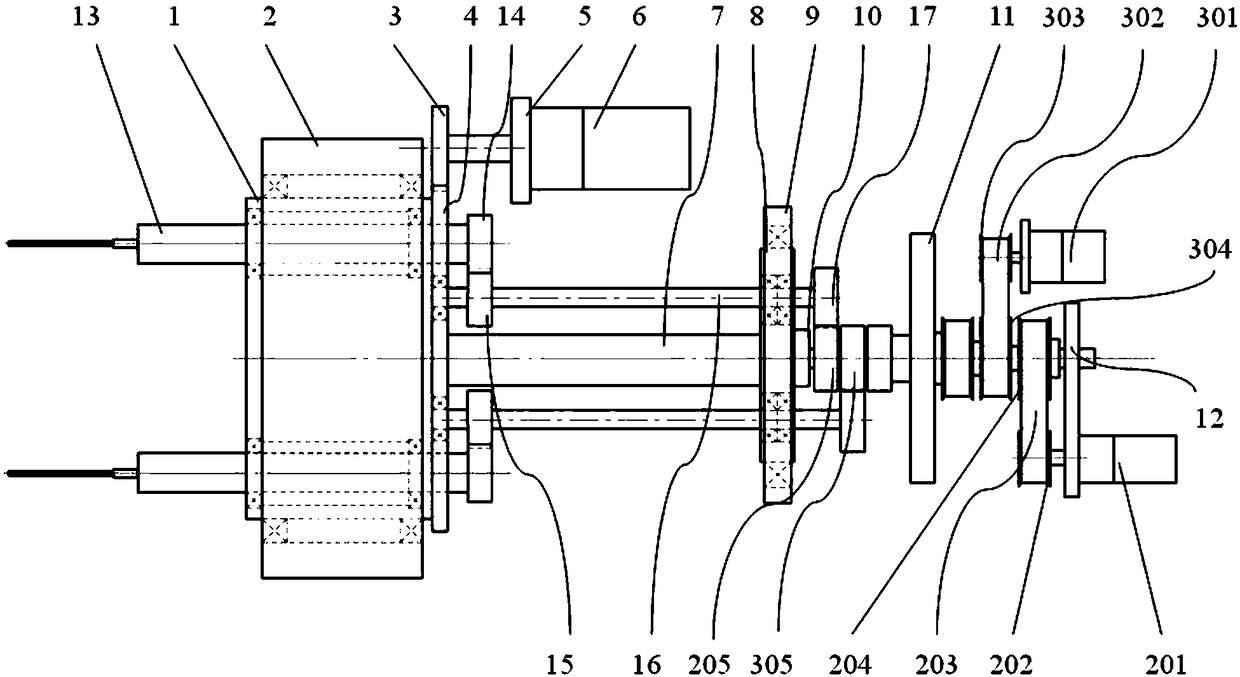

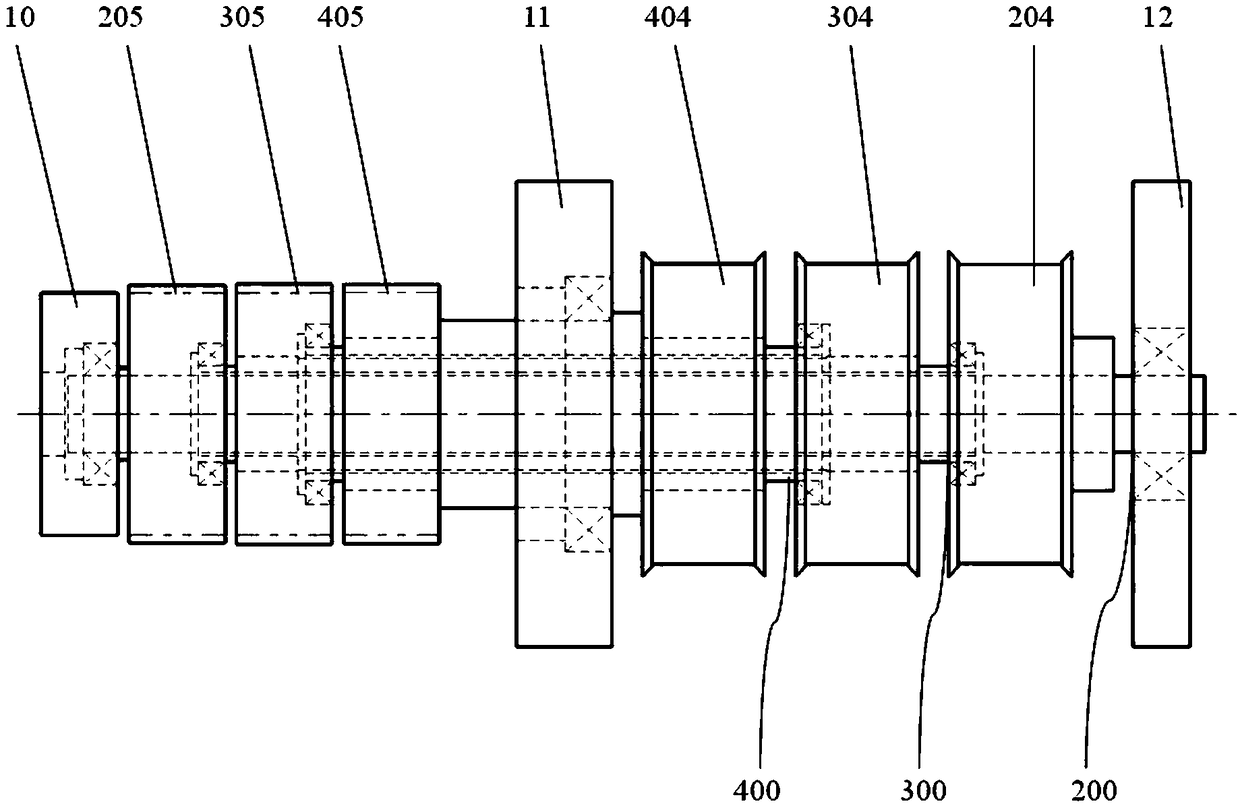

[0023] As shown in the figure: the electric core winding needle rotation and revolution device in the embodiment is mainly composed of two parts: the winding needle revolution mechanism and the needle winding mechanism.

[0024] like figure 1 , figure 2 As shown, the needle roll revolution mechanism is mainly composed of a turret 1, a turret base 2, a revolution drive gear 3, a revolution driven gear 4, a revolution motor frame 5, a revolution drive component 6, a revolution connecting shaft 7, a revolution turntable 8 and The turntable seat 9 is composed of the turret seat 2 and the turntable seat 9 are fixedly installed, and the revolution motor frame 5 is fixedly installed; the turret 1 is assembled in the turret seat 2 through bearing support, and the revolution driven gear 4 Fixedly installed on the rear end of the turret 1, the revolving turntable 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com