A kind of preparation method of polyethylene catalyst

A catalyst and polyethylene technology, applied in the preparation of polyethylene catalysts, polyethylene catalysts use single ethylene as a raw material to prepare high-branched polyethylene, to achieve the effect of reducing production costs, good particle shape, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

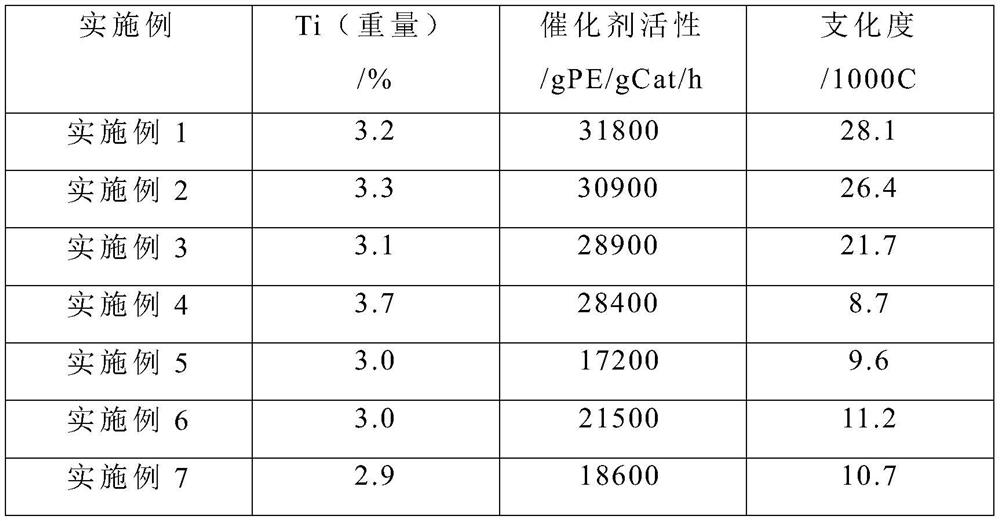

Examples

Embodiment 1

[0051] (1) prepare magnesium alkoxide solution

[0052] Add 100ml of cyclohexanone into a reaction vessel with a condensing device fully replaced with nitrogen, pass through nitrogen, slowly add 0.1 mole of ethoxymagnesium with the stirring turned on, and raise the temperature to 100°C for 3 hours. After the reaction is completed, Filtrate hot, and filter out the residue under the reaction vessel under the protection of nitrogen.

[0053] (2) Treatment of cyanocene compounds

[0054] Add 0.02 mol of IndCpZrCl to another reaction vessel fully replaced with nitrogen 2 , add 20ml of 10% MAO toluene solution under stirring, raise the temperature to 100°C and react for 4 hours, cool to room temperature after the reaction is completed, filter off the supernatant, wash with hexane, dry and add to the solution as described in (1) above for later use .

[0055] (3) Catalyst preparation

[0056] Add the solution obtained in the above (2) into a nitrogen-protected spray dryer, and se...

Embodiment 2

[0058] (1) prepare magnesium alkoxide solution

[0059] Add 85ml of isooctyl alcohol into a reaction vessel with a condensing device fully replaced with nitrogen, pass through nitrogen, slowly add 0.1 mole of ethoxymagnesium with the stirring turned on, and raise the temperature to 85°C for 3 hours. After the reaction is completed, Filtrate hot, and filter out the residue under the reaction vessel under the protection of nitrogen.

[0060] (2) Treatment of cyanocene compounds

[0061] In another reaction vessel fully replaced with nitrogen, add 0.01, mole Cp 2 ZrCl 2 , add 30ml of 10% MAO toluene solution under stirring, raise the temperature to 100°C and react for 4 hours, after the reaction is completed, cool to room temperature, filter off the supernatant, wash with hexane, dry and add to the solution as described in (1) above spare.

[0062] (3) Catalyst preparation

[0063] Add the solution obtained in the above (2) into a nitrogen-protected spray dryer, set the feed...

Embodiment 3

[0065] (1) prepare magnesium alkoxide solution

[0066] Add 110 ml of cyclohexanone and propylene oxide mixture (volume ratio 1:1) into a reaction vessel with a condensing device fully replaced with nitrogen, feed nitrogen, and slowly add 0.03 mole of methoxy Magnesium, heated up to 30°C to react for 3 hours, hot filtered after the reaction, and filtered off the residue under the container under the protection of nitrogen.

[0067] (2) Treatment of cyanocene compounds

[0068] Add 0.01 mole of Cp to another reaction vessel fully replaced with nitrogen 2 ZrMe 2 , add 20ml of 10% MAO toluene solution under stirring, raise the temperature to 100°C and react for 4 hours, cool to room temperature after the reaction is completed, filter off the supernatant, wash with hexane, dry and add to the solution as described in (1) above for later use .

[0069] (3) Catalyst preparation

[0070] Add the solution obtained in the above (2) into a nitrogen-protected spray dryer, set the fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com