Back cover of washing machine

A washing machine and back cover technology, which is applied in the field of mechanical washing, can solve problems such as easy damage, easy wear, and unreasonable structural design, and achieve the effects of reasonable overall design, reasonable integration of resources, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

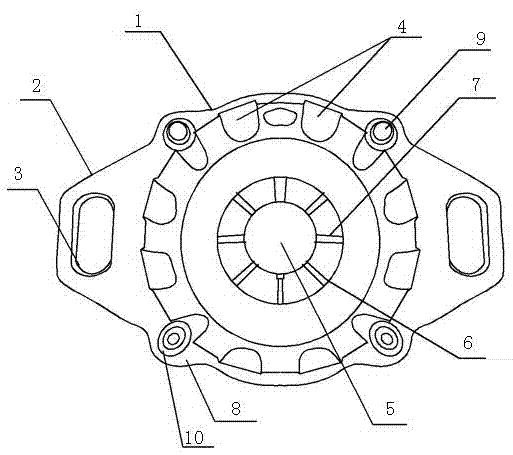

[0014] Such as figure 1 As shown, a back cover for a washing machine includes a back cover body 1, and the back cover body 1 is symmetrically extended outwardly with snap-in fixing ears 2, and the snap-in fixing ears 2 are provided with fixing holes 3, and the side of the back cover body 1 is evenly spaced. A heat dissipation observation hole 4 is provided, and a motor shaft positioning hole 5 is provided on the back cover body 1, and a reinforcing ring 6 is extended from the motor shaft positioning hole 5, and an L-shaped reinforcing rib 7 is provided outside the reinforcing ring 6.

[0015] The back cover body 1 is symmetrically extended outwardly with a connecting reinforcing flange 8 , and a connecting hole 9 is provided on the connecting reinforcing flange 8 . A countersunk head 10 is provided on the outer edge of the connecting hole 9, and four c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com