Edge chamfering equipment for small-size round hard and brittle material sheets and edge chamfering method of edge chamfering equipment

A hard and brittle material, small-sized technology, applied in the field of beveling equipment for small-sized round hard and brittle material sheets, can solve the problems of inconvenient use, scrapped processed parts, high cost, etc., and achieve reasonable overall design, convenient maintenance and saving The effect of training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

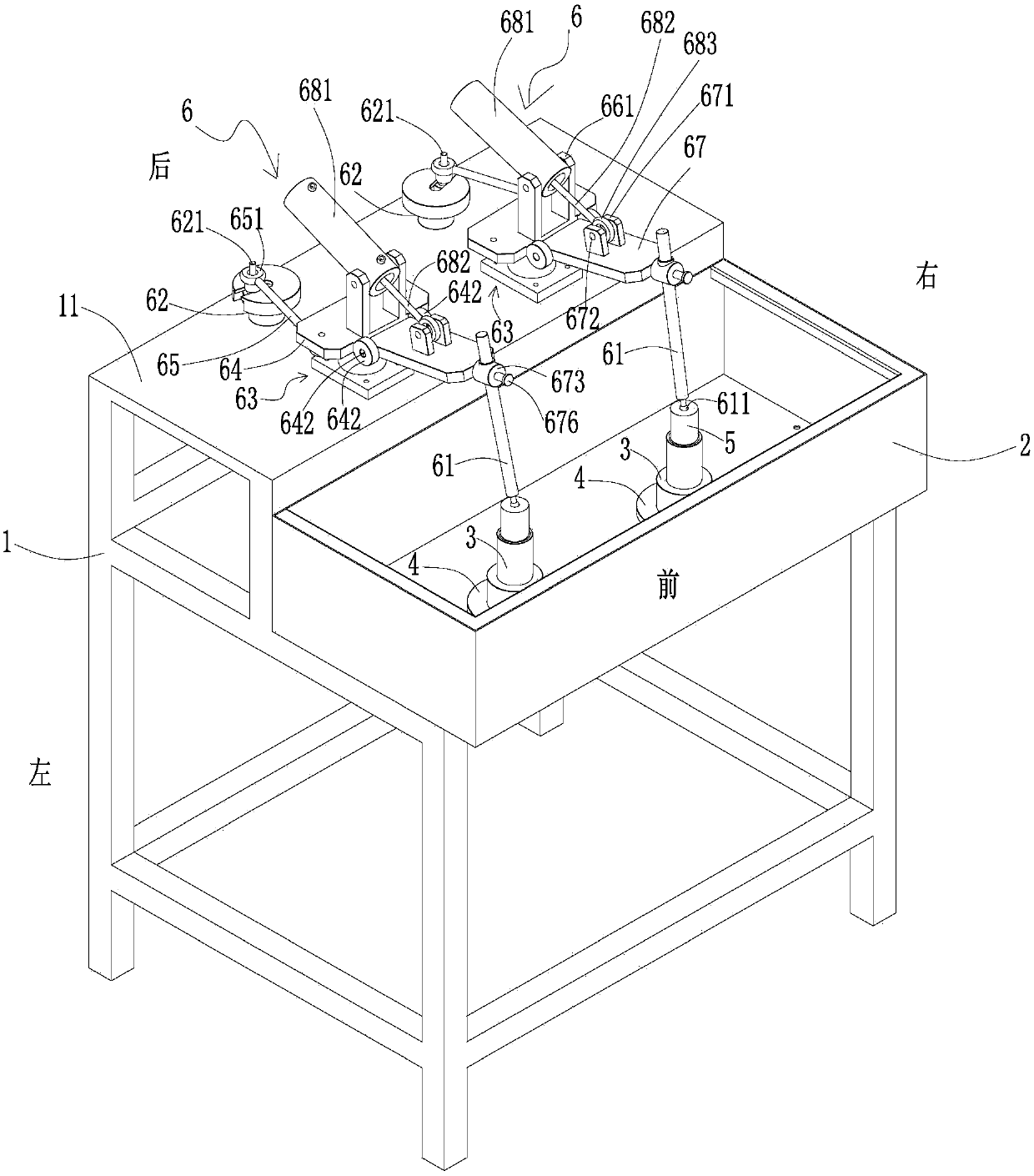

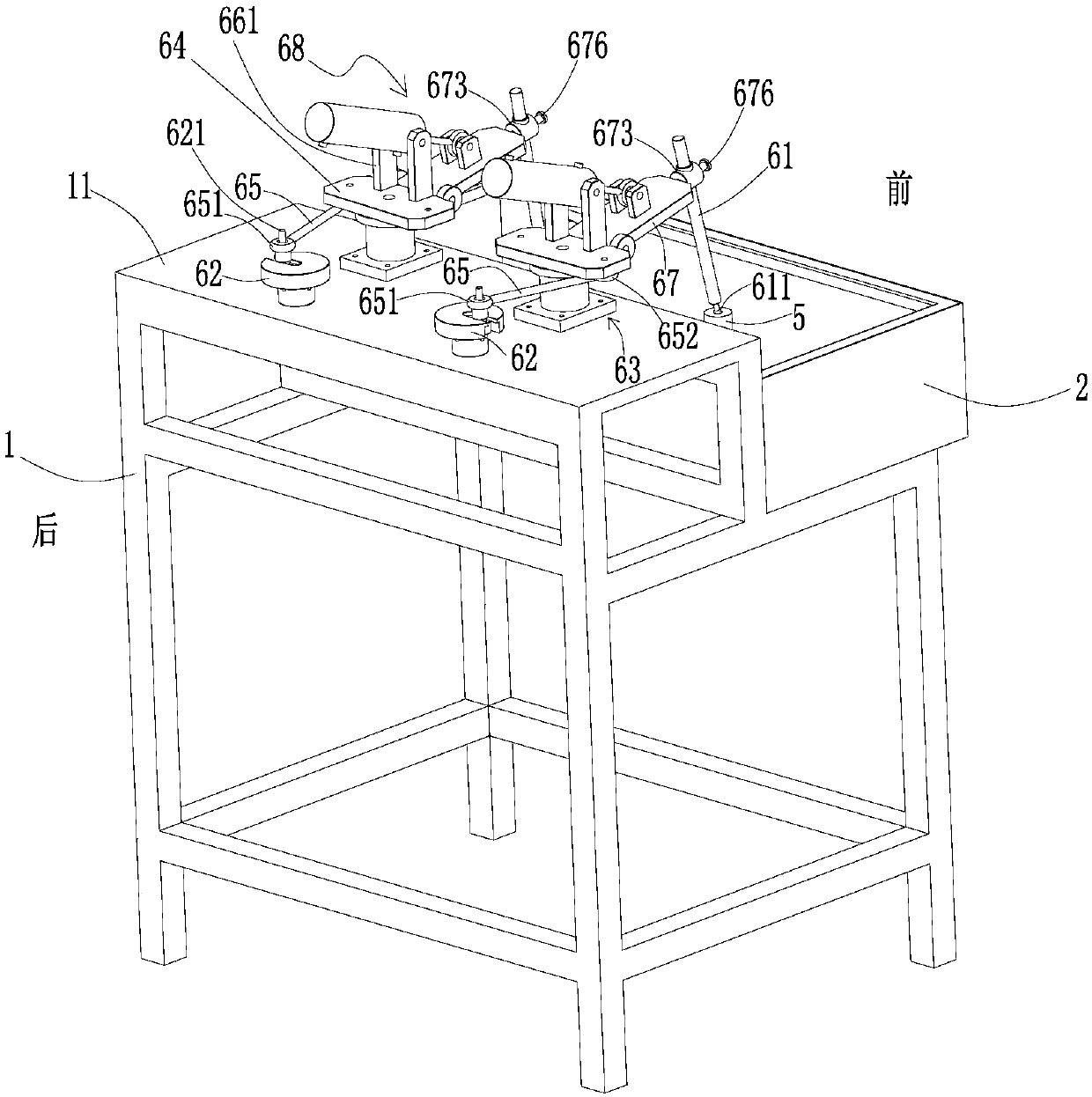

[0035] For the convenience of description, use figure 1 Chinese characters refer to the definitions of "front", "rear", "left", and "right" in the examples, with sapphire as a representative instead of hard and brittle materials.

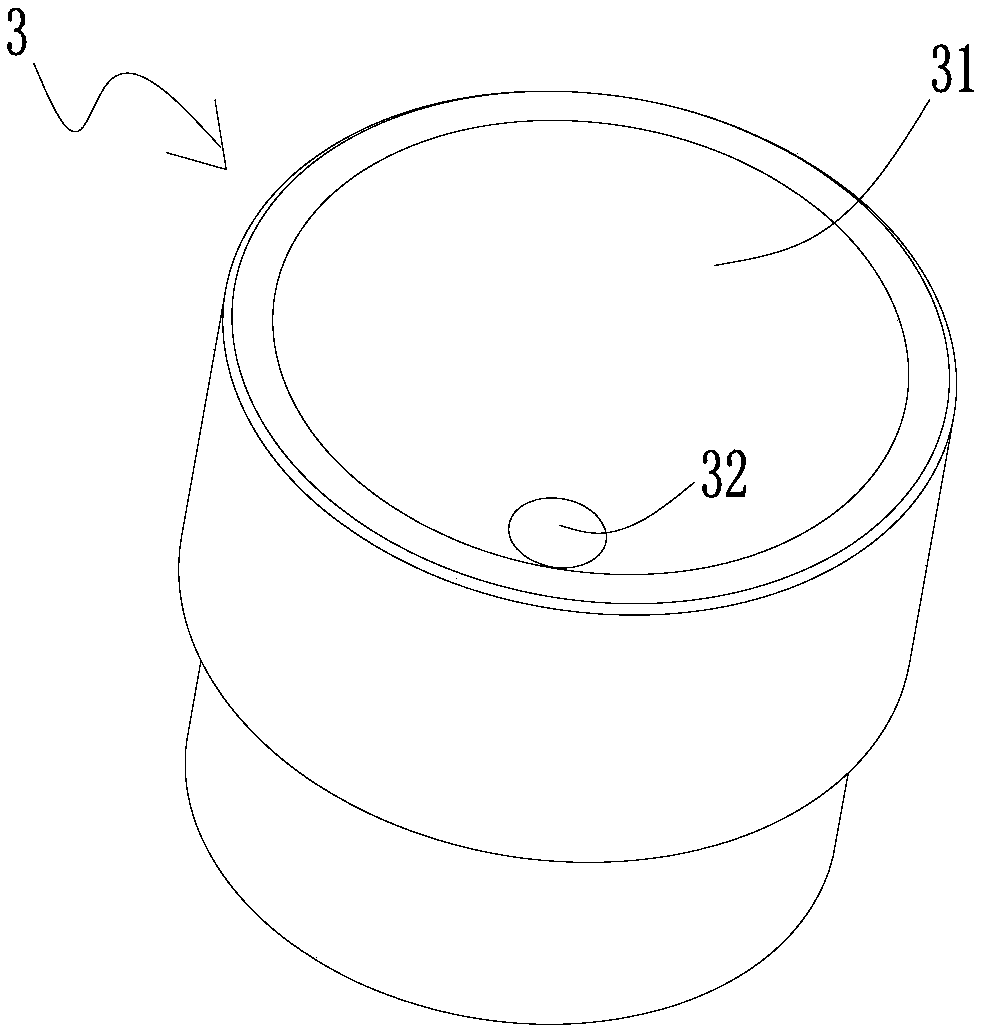

[0036] Such as Figure 1 ~ Figure 7 As shown, a small-size round hard and brittle material sheet beveling device includes a bracket 1, a water tank 2, an sand bowl 3, a rotating motor 4, and a round sapphire sheet (ie, a round hard and brittle material sheet). At the bottom of the emery bowl 3, an indenter 5 that makes the sapphire sheet relatively rotate relative to the emery bowl 3, and an eccentric pressurizing system 6 that rotates eccentrically to apply pressure to the indenter 5 to ensure uniform beveling of the sapphire sheet.

[0037] The top surface of the support 1 is stepped, the water tank 2 is arranged on the lower step of the support 1, the rotating motor 4 is arranged at the bottom of the water tank 2, and the sand bowl 3 can be rotated at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com