Novel rust-proof screw

A screw, a new type of technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of unreachable, good anti-rust effect of screws, waste of anti-rust agent, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

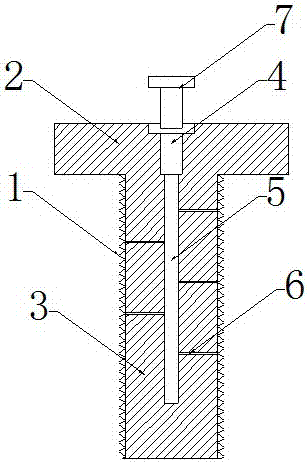

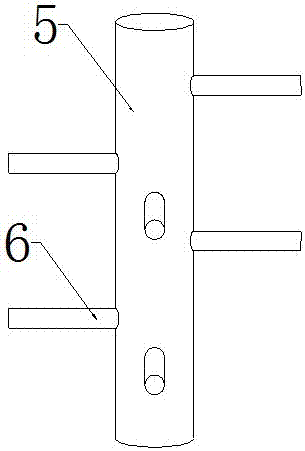

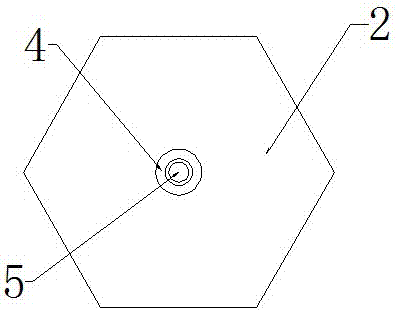

[0017] like figure 1 - Shown in 3: a new type of anti-rust screw, including a screw body 1, the screw body 1 is composed of a conventional screw head 2 and a screw rod 3, and the center position of the screw head 2 is provided with an oil injection hole 4, so The central position of the screw rod 3 is vertically and vertically arranged with an oil storage tank 5, and the oil filling hole 4 communicates with the oil storage tank 5, and the oil storage tank 5 is set horizontally and vertically on the basis of the oil storage tank vertically arranged on the ground. There is an oil guide channel 6, and the said oil guide channel 6 radiates outwards in a radial shape and penetrates the screw rod 3 to communicate with the outside, and the said oil injection hole 4 has a T-shaped structure, and a T-shaped rubber plug 7 is provided with it .

[0018] The number of the oil guide passages 6 set is 10.

[0019] There is only one oil guide channel 6 on the cross-section of a screw rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com