A Bending Detection Method of Steam Turbine Major Shaft

A detection method and steam turbine technology, which are applied in the testing of mechanical parts, the testing of machine/structural parts, and measuring devices, etc., can solve the problems of shortening the idle time of shutdown, neglecting the judgment of the curvature of the major shaft, and achieving the elimination of thermal bending, The effect of preventing untimely processing and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementation described here is only used to explain the invention, not to limit the utility model.

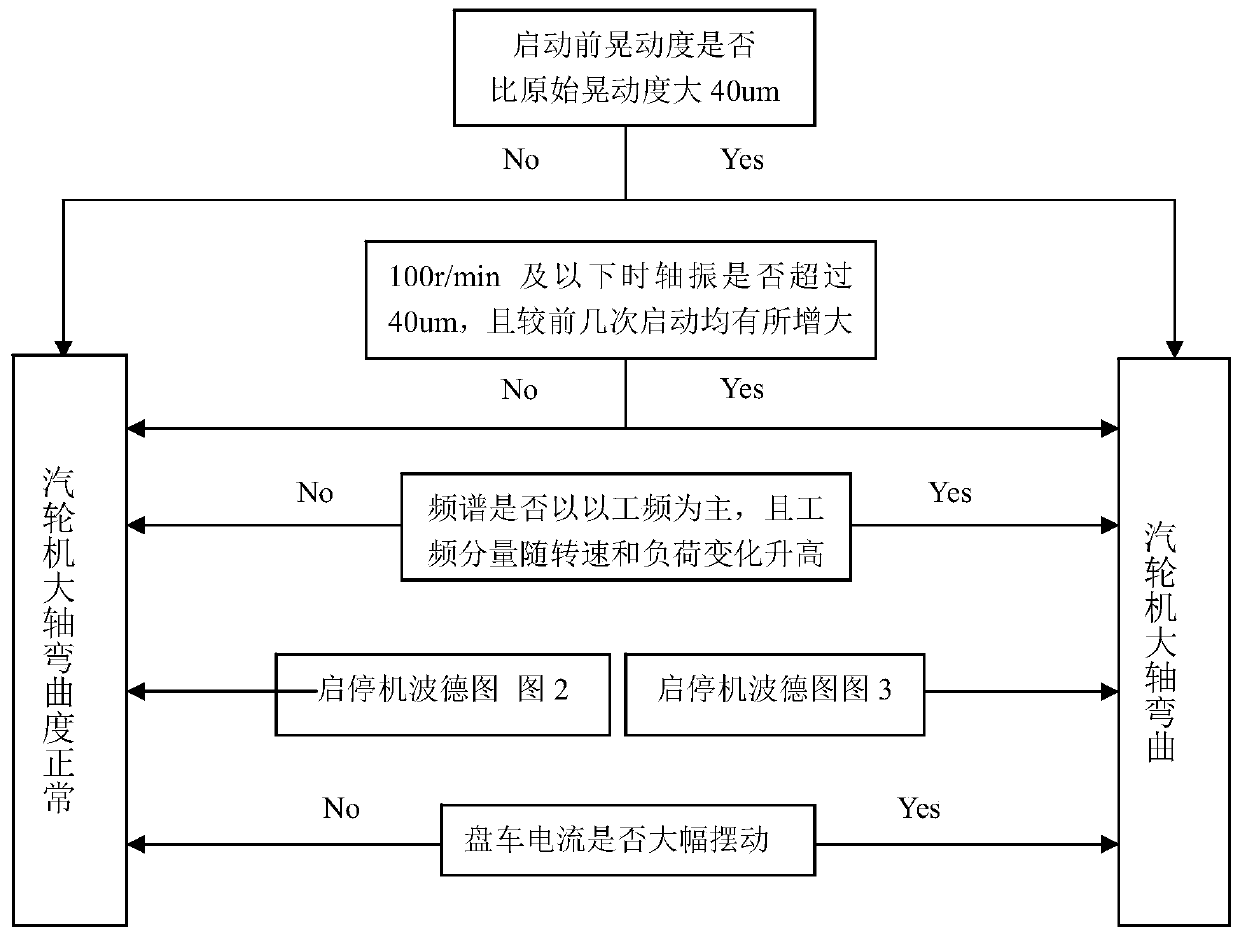

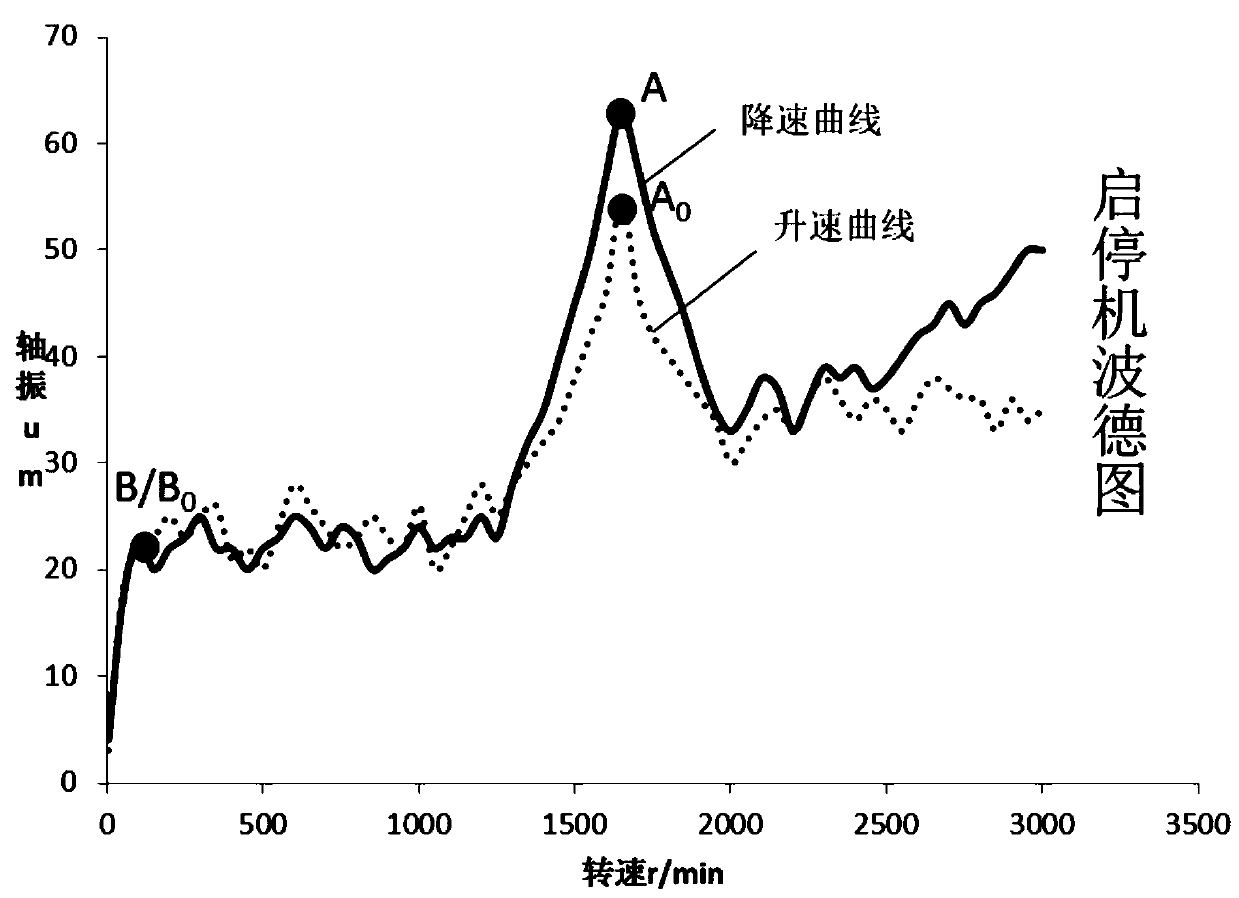

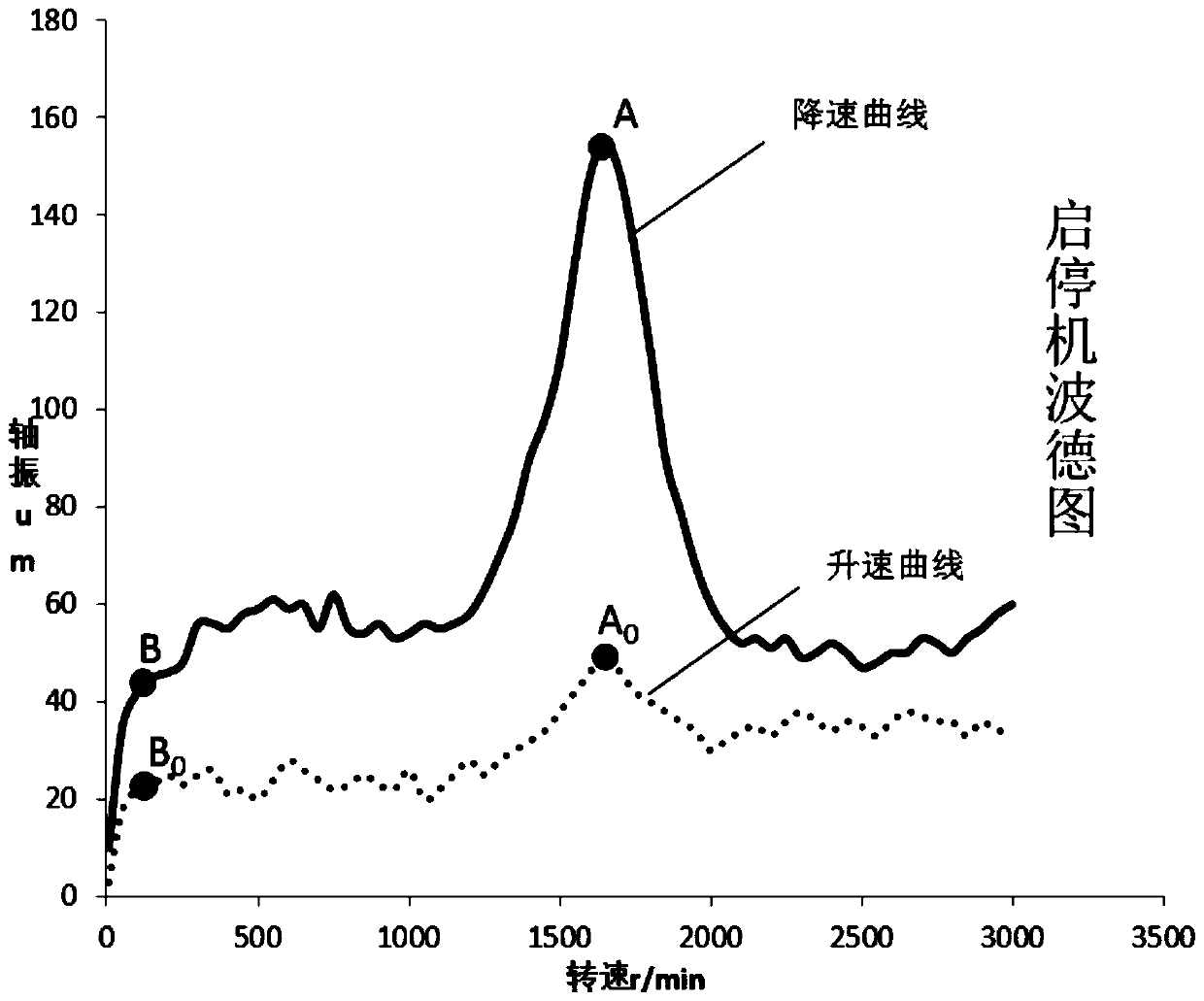

[0030] In order to achieve the above requirements and solve technical problems, such as figure 1 As shown, the method for judging the large shaft bending of the steam turbine used in the present invention uses an online vibration monitoring and analysis system to monitor the vibration of the steam turbine, and record the vibration curves of the unit during startup and shutdown; The Bode plot, such as figure 2 , 3 shown, where figure 2 , 3 The speed-up curve marked in is the Bode diagram of the shafting vibration changing with the speed during the start-up process, and the deceleration curve shows the Bode diagram of the shafting vibration changing with the speed during the shutdown proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com