Bagging machine frame

A bagging machine and frame technology, applied in plant protection covers, botanical equipment and methods, gardening, etc., can solve the problems of affecting the uniformity of light received by young fruits, affecting the quality of bagging, and the edge of the bag is not neat enough, etc., to achieve Ensure the bag sealing environment and light transmission uniformity, ensure the quality of bag sealing and bagging effect, and avoid the effect of uneven bag mouth or deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

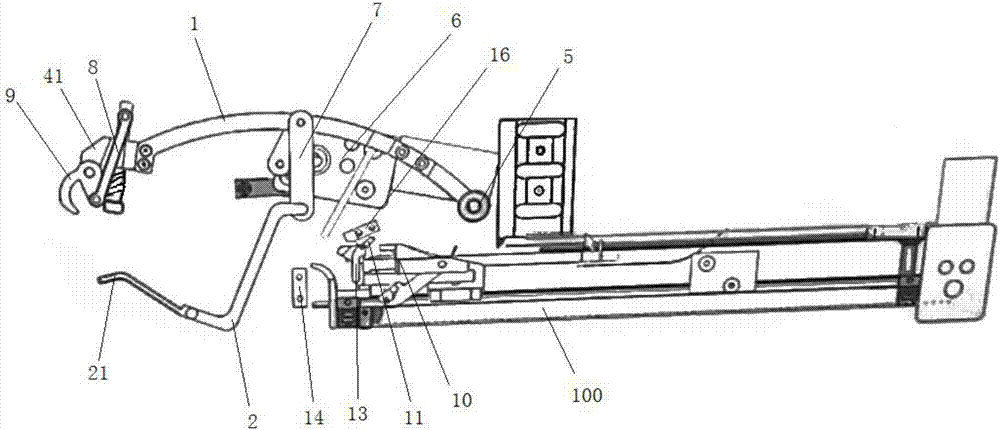

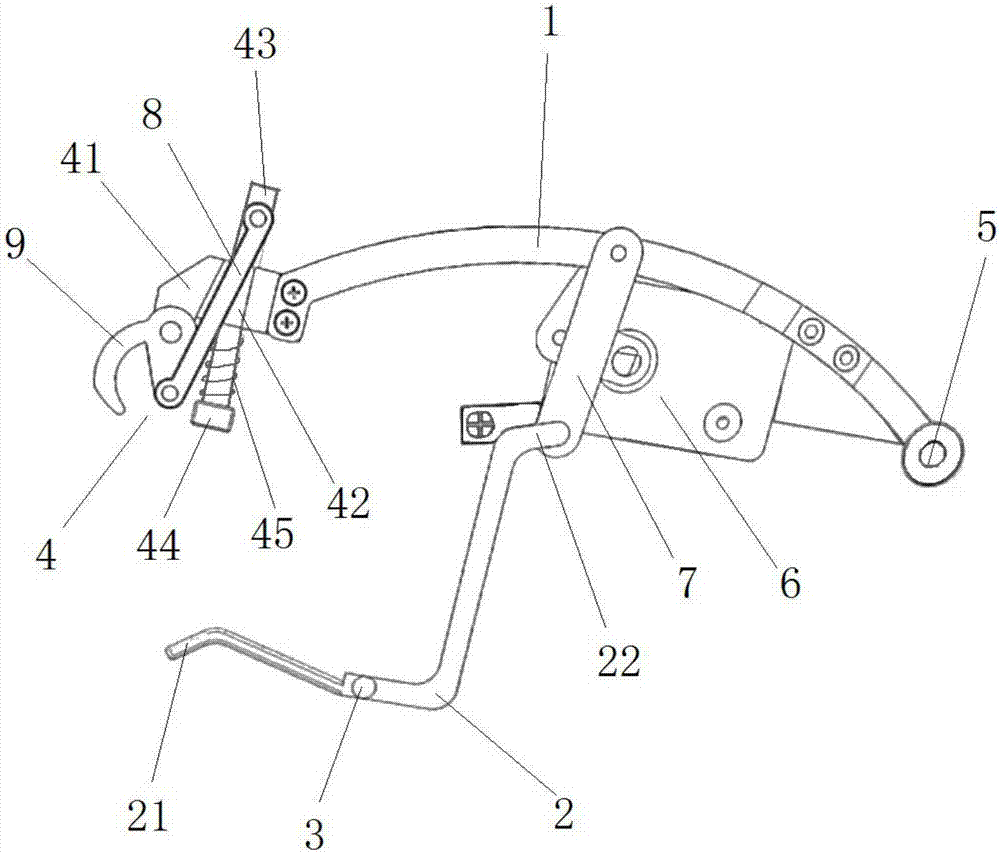

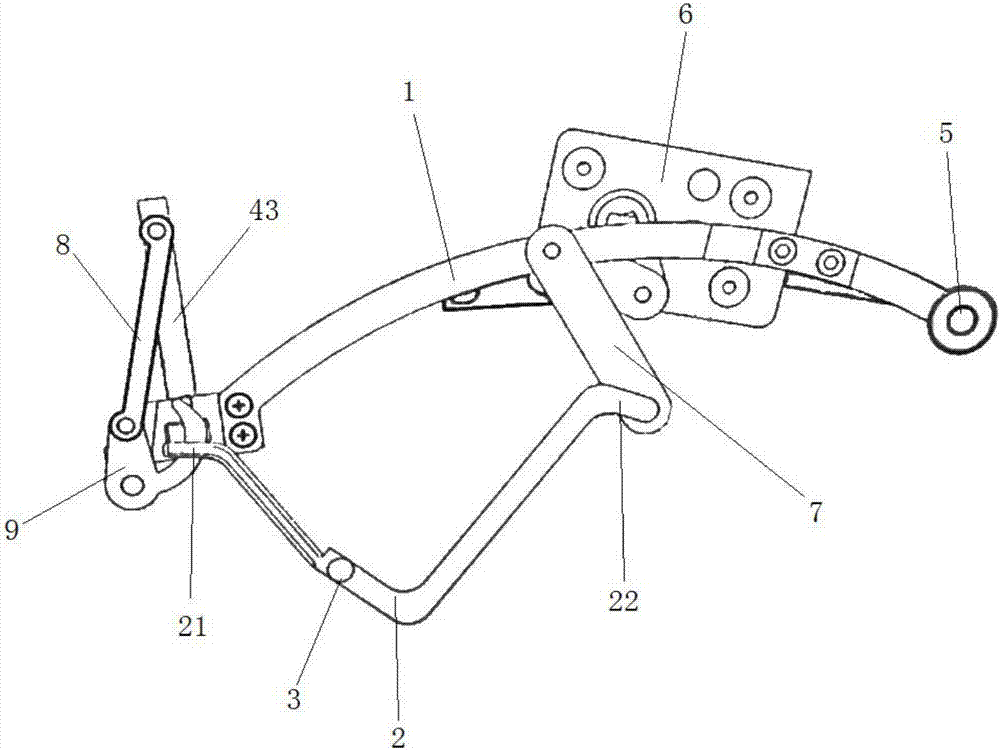

[0026] see Figure 1-3 , a bagging machine frame, the front end of the bagging machine frame 100 is hinged with an upper press frame 1 and a fork plate 2, and the position close to the front end of the bagging machine frame 100 is provided with a bagging machine stretch bag mechanism, the middle part of the fork plate 2 is hinged on the bagging machine frame through the first hinge shaft 3, and one end of the upper pressing frame 1 ( figure 1 Left end) is provided with enveloping bag part 4, one end ( figure 1 The right end) is hinged on the frame of the bagging machine through the second hinge shaft 5, and the frame of the bagging machine is provided with a drive that drives the upper pressing frame 1 to approach or move away from the fork plate 2 side. Device 6, the middle part of the upper press frame 1 is hingedly connected with one end of the connecting rod 7, and the other end of the connecting rod 7 is hinged at the end of the fork plate 2 away from the bag sealing par...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap