Intelligent top coal caving control system and method

A control system and top coal caving technology, which can be used in earth-moving drilling, mine roof support, mining equipment, etc., can solve problems such as low efficiency and high labor intensity, reduce labor intensity, improve recovery rate, and avoid irregularities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

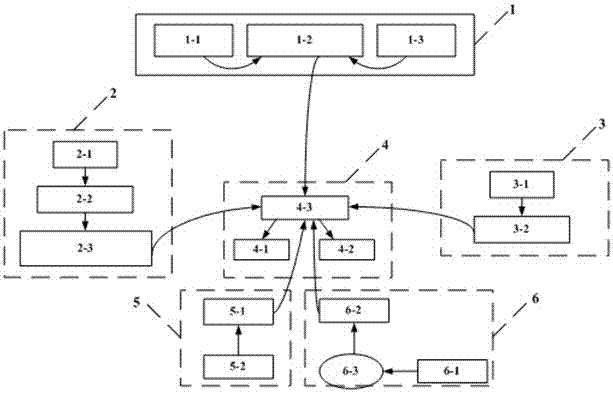

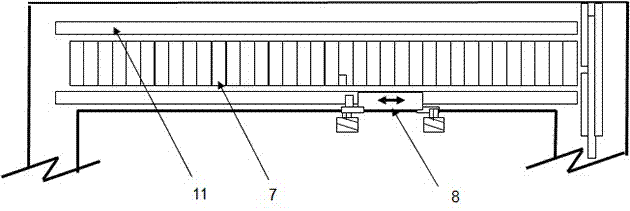

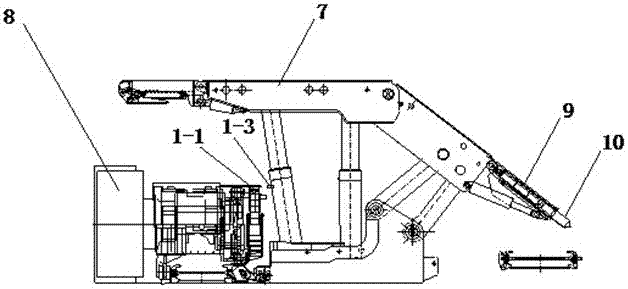

[0035] Such as figure 1 figure 2 image 3 The shown intelligent top-coal caving control system includes data transmission and storage devices, and also includes:

[0036] Coal mining process discrimination system 1, including infrared transmitter 1-1, infrared receiver 1-3, coal mining machine operation identification device 1-2, infrared transmitter 1-1 and infrared receiver 1-3 are used to collect mining coal The motion and position information of the shearer 8 are input to the operation identification device 1-2 of the coal shearer for identification;

[0037] The roof pressure monitoring and forecasting system 2 includes a pressure sensor 2-1, a pressure data acquisition device 2-2, and a roof pressure monitoring and forecasting device 2-3, which are used to collect whether the working face is under pressure and the position of the pressure, and perform pressure forecasting;

[0038] The real-time evaluation system 3 for top-coal caving and caving includes a data colle...

Embodiment 2

[0043] Such as figure 1 figure 2 image 3 As shown, a coal discharging method of an intelligent top coal caving control system comprises the following steps:

[0044] 1) The coal mining process discrimination system 1 identifies the coal cutting process, coal cutting direction and position of the coal shearer 8 in the working face;

[0045] 2) The roof pressure monitoring and prediction system 2 determines whether the working face is under pressure and the position of the pressure;

[0046] 3) Top-coal caving real-time evaluation system 3 evaluates the top-coal caving performance of the working face;

[0047] 4) Coal discharge process decision-making system 4 receives the signal output from roof pressure monitoring and prediction system 2 and top coal caving real-time evaluation system 3 through intelligent coal discharge controller 4-3, and then performs logical operation through intelligent coal discharge controller 4-3 And send control instruction to tail beam 9, inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com